Heat-conducting polymer-base composite material and preparation method thereof

A technology of composite materials and composite material plates, which is applied in the field of thermally conductive polymer-based composite materials and its preparation, and can solve the problems of poor thermal conductivity and high cost of polymer-based composite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

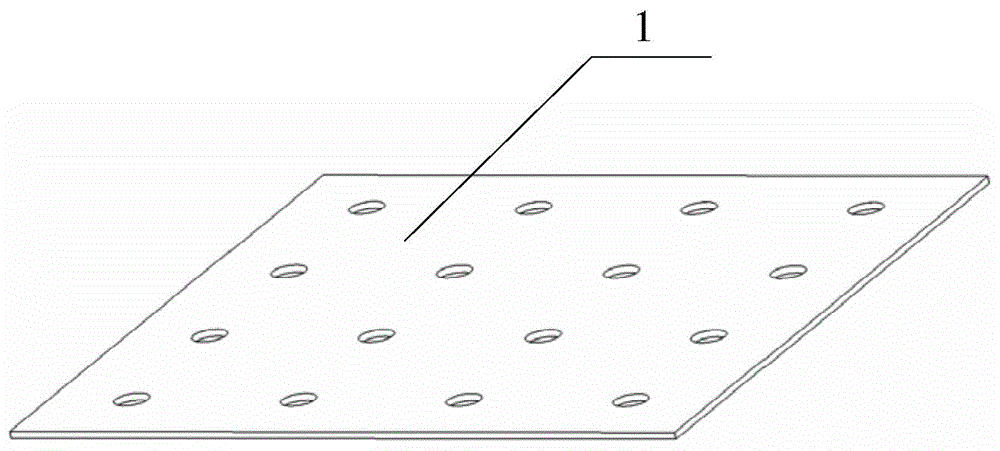

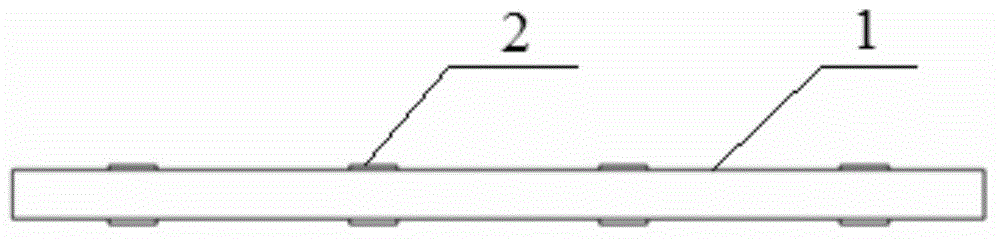

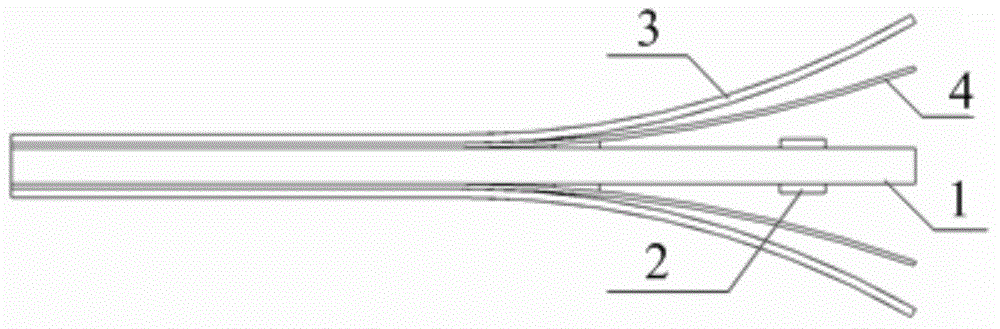

[0083] Embodiment 1: A thermally conductive polymer-based composite material in this embodiment consists of a composite material plate 1 with through holes, a filling material 2 filled in the through holes of the composite material plate 1 with through holes, and a Composed of a membrane material layer 3 on the composite material plate and lower surface of the hole;

[0084] The material of the composite material plate 1 with through holes is a polymer-based composite material;

[0085] The shape of the filling material 2 is cylindrical or quasi-cylindrical, the filling material 2 is a material with a thermal conductivity of 200W / (m·K)~1000W / (m·K), and the filling material 2 The thickness is greater than the thickness of the composite material plate 1 with through holes;

[0086] The material of the film material layer 3 is aluminum foil, copper foil or graphite film;

[0087] The volume ratio of the composite material plate 1 with through holes to the thermally conductive p...

specific Embodiment approach 2

[0090] Embodiment 2: This embodiment is different from Embodiment 1 in that: the filling material 2 is copper, aluminum or carbon fiber. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0091] Embodiment 3: This embodiment is different from Embodiment 1 or Embodiment 2 in that: the diameter of the filling material 2 is 0.2mm-5mm. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com