Package substrate and its manufacturing method and LED package structure based on the package substrate

A technology for LED packaging and packaging substrates, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of complex manufacturing process, rising PN junction junction temperature, aging of chips and packaging materials, etc., to simplify the manufacturing process, Reduced production cost and increased installation height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

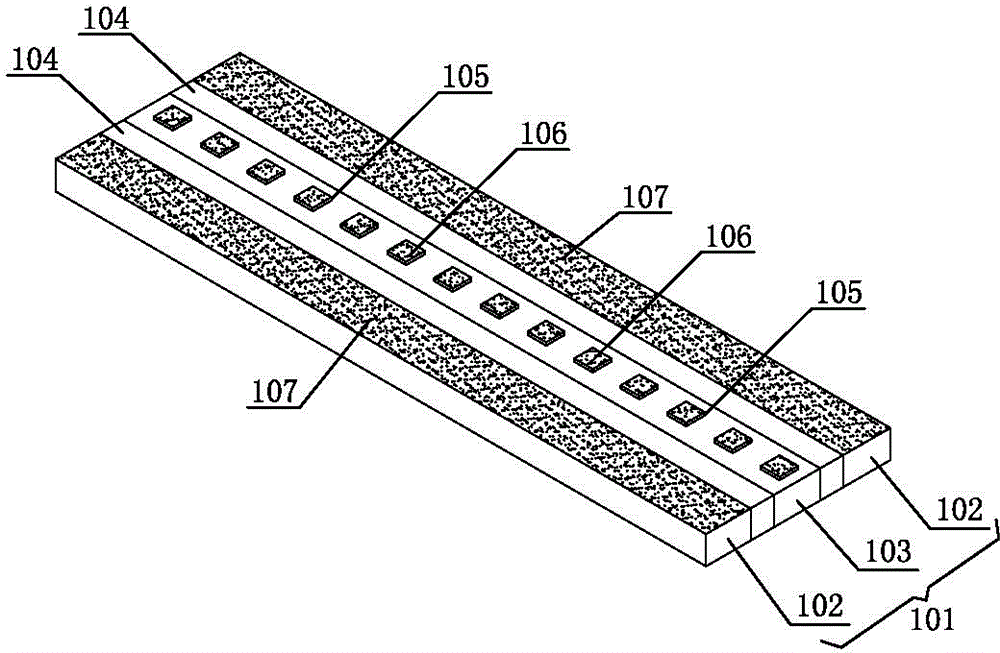

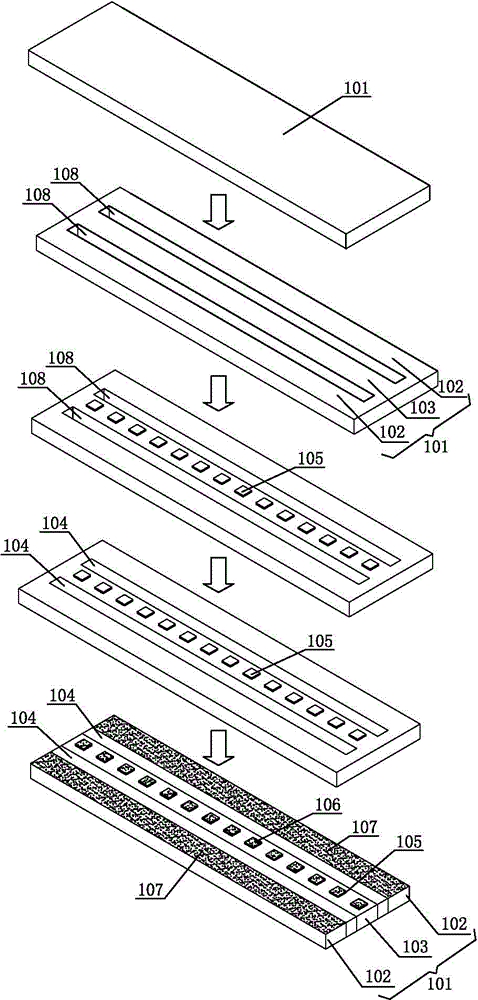

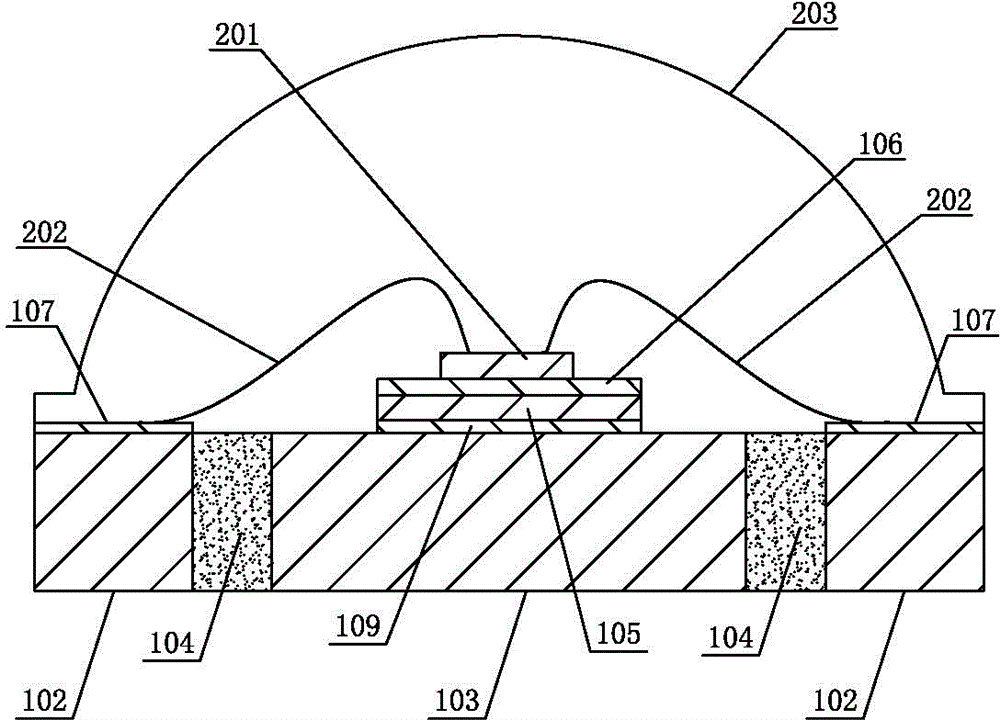

[0028] see figure 1 , the package substrate shown in the figure includes: a copper heat sink plate 101, two insulating strips 104 are embedded on the copper heat sink plate 101, and the two insulating strips 104 separate the copper heat sink plate 101 into Electrode 102, welding strip 103, three regions of electrode 102, welding strip 103 is positioned between two electrodes 102; The tungsten-copper alloy boss 105 that fixes LED chip passes silver-copper solder layer (see image 3 ) are welded on the welding strip 103, and electroplating layers 106 and 107 are respectively provided on the surfaces of the tungsten-copper alloy boss 105 and the two electrodes 102. Preferably, the electroplating layers 106 and 107 are provided with two layers of nickel electroplating layer (not shown) and silver electroplating layer (not shown in the figure) from the inside to the outside, and the silver electroplating layer covers the nickel electroplating layer; or, the nickel electroplating la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com