Heat sink material for energy-saving LED lamp

A technology of LED lamps and heat dissipation materials, applied in the field of heat dissipation, can solve problems such as insufficient insulation performance, large thermal conductivity, and good heat dissipation effect, and achieve excellent heat conduction and heat dissipation performance, high hardness and mechanical properties, and high environmental heat dissipation. Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

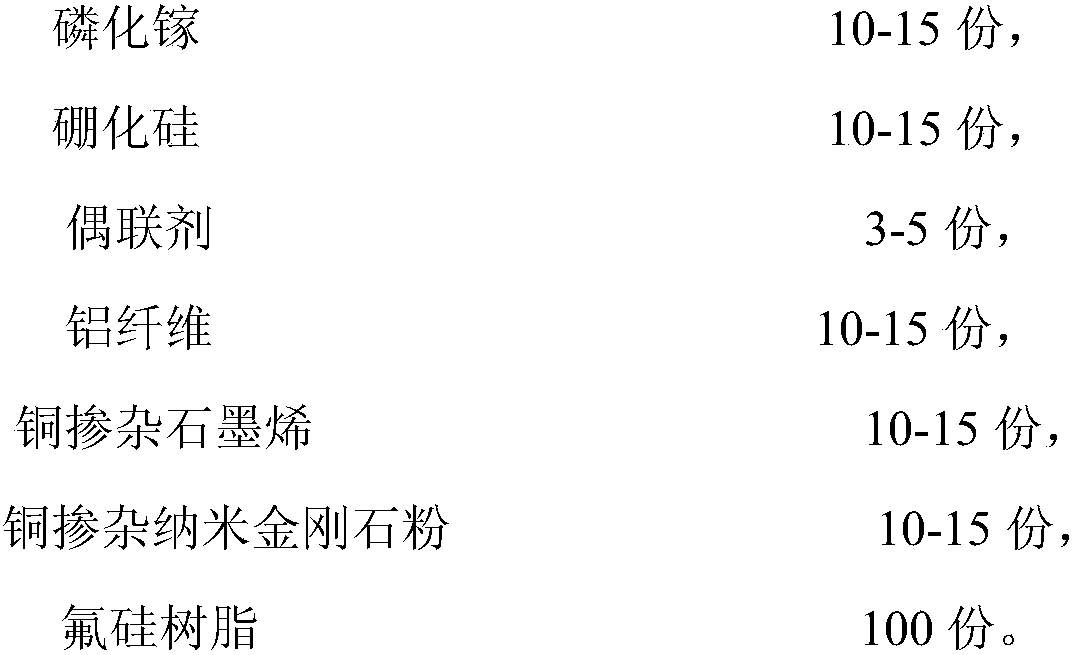

[0026] A heat dissipation material for an energy-saving LED lamp, consisting of the following components in parts by weight:

[0027]

[0028] Wherein, the preparation method of copper-doped graphene comprises the following steps:

[0029] 1) Graphene surface modification: Disperse 60 g of graphene in 300 g of acetonitrile, then add 30 g of triethoxychlorosilane, stir at room temperature for 1 hour, add 10 g of melamine, and reflux at 60 ° C for 5 hours, Then filter, wash 5 times with ethanol, and put into a vacuum drying oven at 60° C. for 8 hours;

[0030] 2) Preparation of copper-doped graphene: the product in step 1) was immersed in an aqueous solution of 1mol / L chlorocupric acid at 50°C for 20 hours, and then put into 5mol / L hydroboration at 50°C Sodium aqueous solution for 20 hours, then filter, take the filter cake and dry it in a vacuum oven at 60°C for 12 hours;

[0031] The preparation method of copper-doped nano-diamond powder comprises the steps:

[0032] 1) ...

Embodiment 2

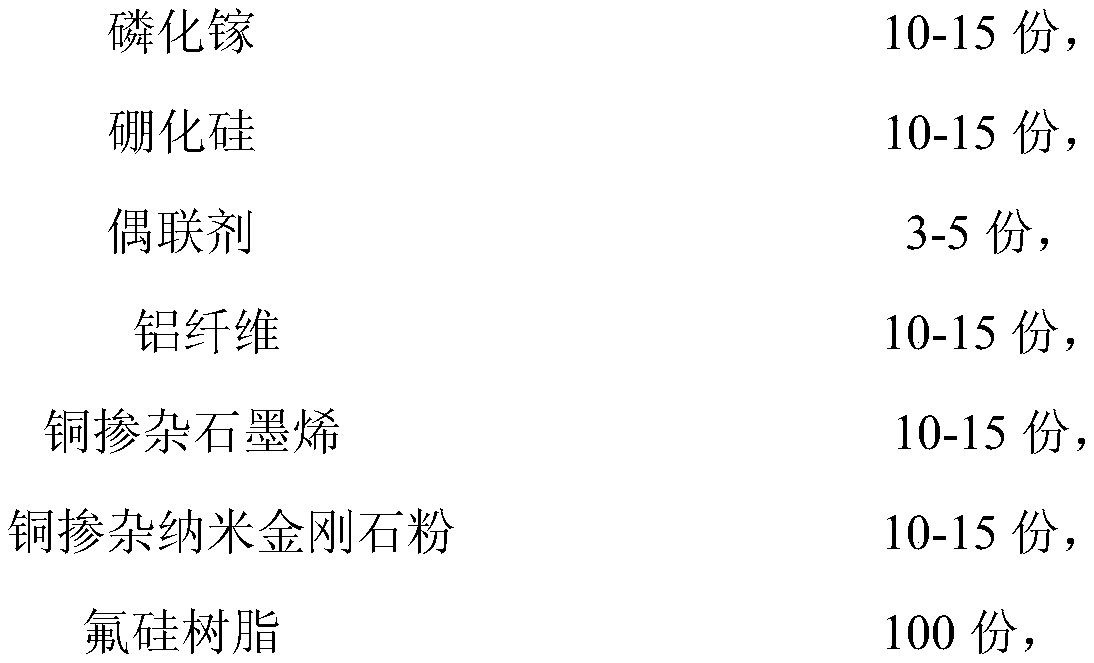

[0036] A heat dissipation material for an energy-saving LED lamp, consisting of the following components in parts by weight:

[0037]

[0038] Wherein, the preparation method of copper-doped graphene comprises the following steps:

[0039] 1) Graphene surface modification: Disperse 70 g of graphene in 350 g of acetonitrile, then add 30 g of triethoxychlorosilane, stir at room temperature for 1.5 hours, add 10 g of melamine, and reflux at 70 ° C for 6 hours. Then filter, wash 6 times with ethanol, put into a vacuum oven at 70°C and dry for 9 hours;

[0040] 2) Preparation of copper-doped graphene: soak the product in step 1) in an aqueous solution of 2mol / L chlorocupric acid at 55°C for 25 hours, then put it into 7mol / L hydroboration at 55°C Sodium aqueous solution for 25 hours, then filter, take the filter cake and dry it in a vacuum oven at 70°C for 14 hours;

[0041] The preparation method of copper-doped nano-diamond powder comprises the steps:

[0042] 1) Nano-diamon...

Embodiment 3

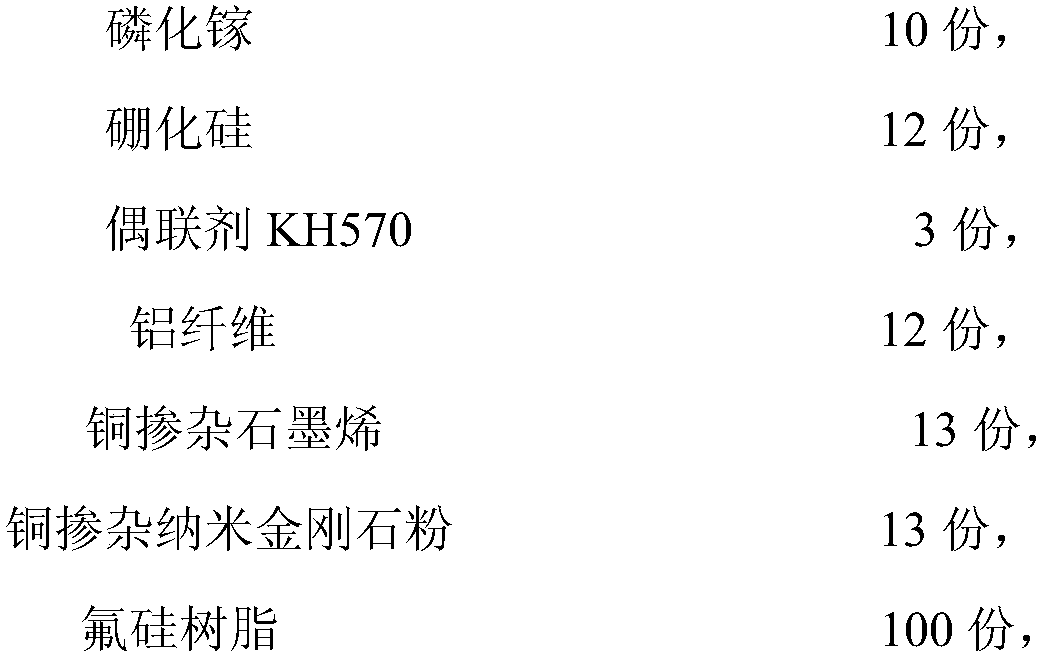

[0046] A heat dissipation material for an energy-saving LED lamp, consisting of the following components in parts by weight:

[0047]

[0048] Wherein, the preparation method of copper-doped graphene comprises the following steps:

[0049]1) Graphene surface modification: Disperse 74g of graphene in 340g of acetonitrile, then add 30g of triethoxychlorosilane, stir at room temperature for 2 hours, add 10g of melamine, and reflux at 70°C for 7 hours. Then filter, wash 7 times with ethanol, and put into a vacuum drying oven at 77° C. for 10 hours;

[0050] 2) Preparation of copper-doped graphene: the product in step 1) was immersed in an aqueous solution of 3mol / L chlorocupric acid at 60°C for 20 hours, and then put into 8mol / L hydroboration at 50°C Sodium aqueous solution for 27 hours, then filter, take the filter cake and put it in a vacuum drying oven at 76°C for 13 hours;

[0051] The preparation method of copper-doped nano-diamond powder comprises the steps:

[0052] 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com