Conveying equipment for tobacco materials

A technology for conveying equipment and tobacco, which is applied in the fields of tobacco, conveyors, and cigarette manufacturing. It can solve the problems of conveyor belt swelling and bandwidth limitation, and achieve the effects of increasing conveying width, reducing expansion characteristics, and improving conveying power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

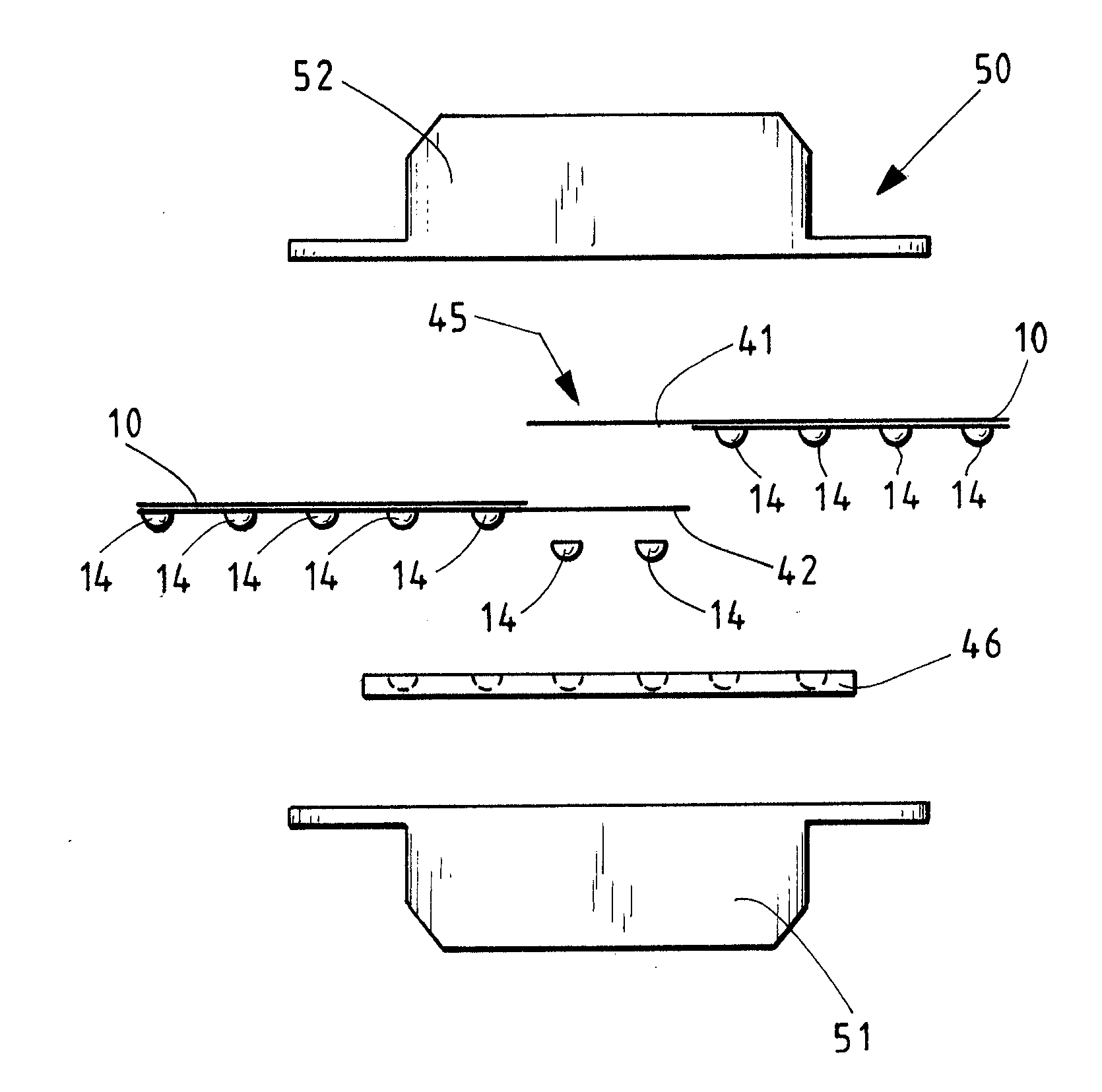

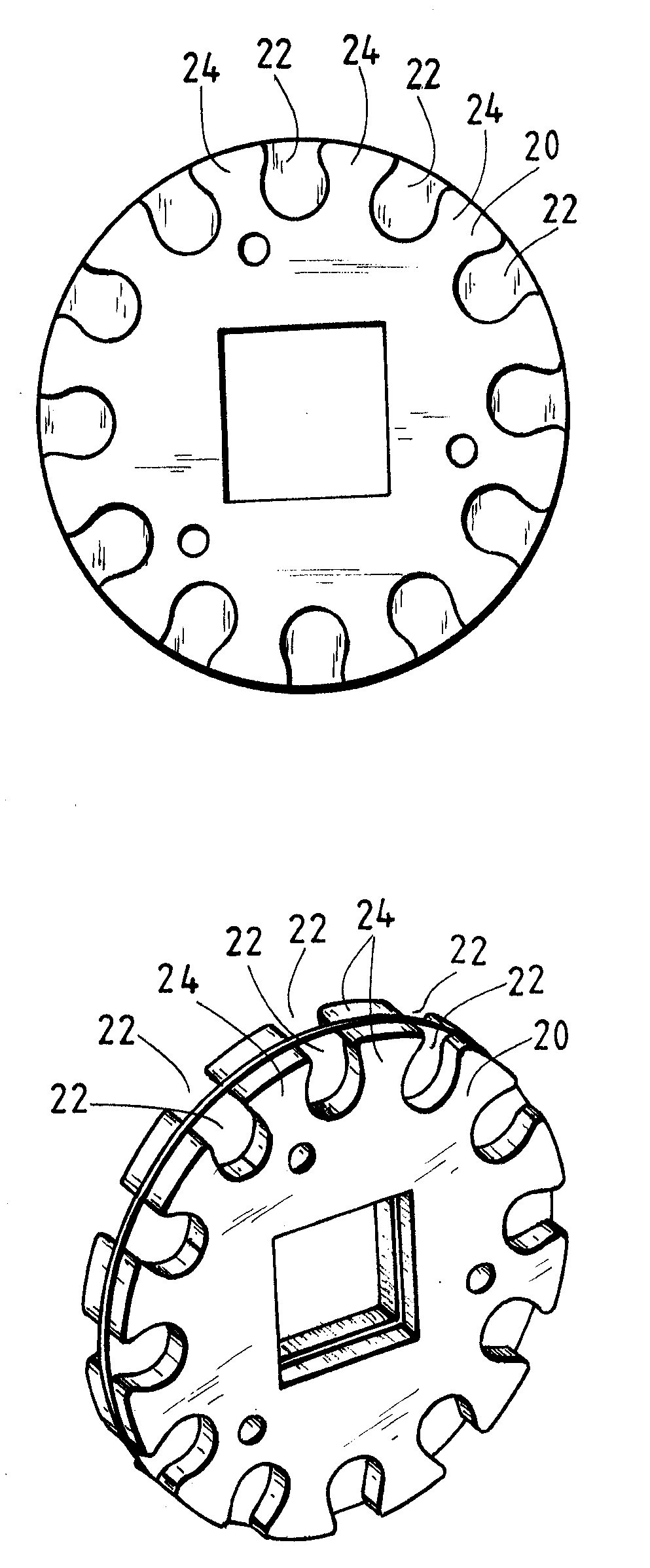

[0048] figure 1 The conveying equipment F of the tobacco processing industry is partially shown in side view. The conveying device F has a conveyor formed by a conveying fabric belt 10 . The conveyor fabric 10 has a support surface 11 on its outer side and a running surface 12 on its inner side. The running surface 12 of the conveyor fabric 10 also has cams 14 arranged at regular intervals, which engage on the conveyor device F in the deflection region of the conveyor fabric 10 to be driven by a drive (not shown here). In the lug receiving part 22 of the lug wheel 20.

[0049] The cam wheel 20 forming the conveyor wheel has cam receptacles 22 in the circumferential direction, into which the cams 14 of the conveyor fabric web 10 engage. For this purpose, the cams 14 welded or bonded to the running surface 12 of the conveyor fabric 10 are designed to be complementary in shape and function to the cam receptacles 22 of the cam wheel 20 .

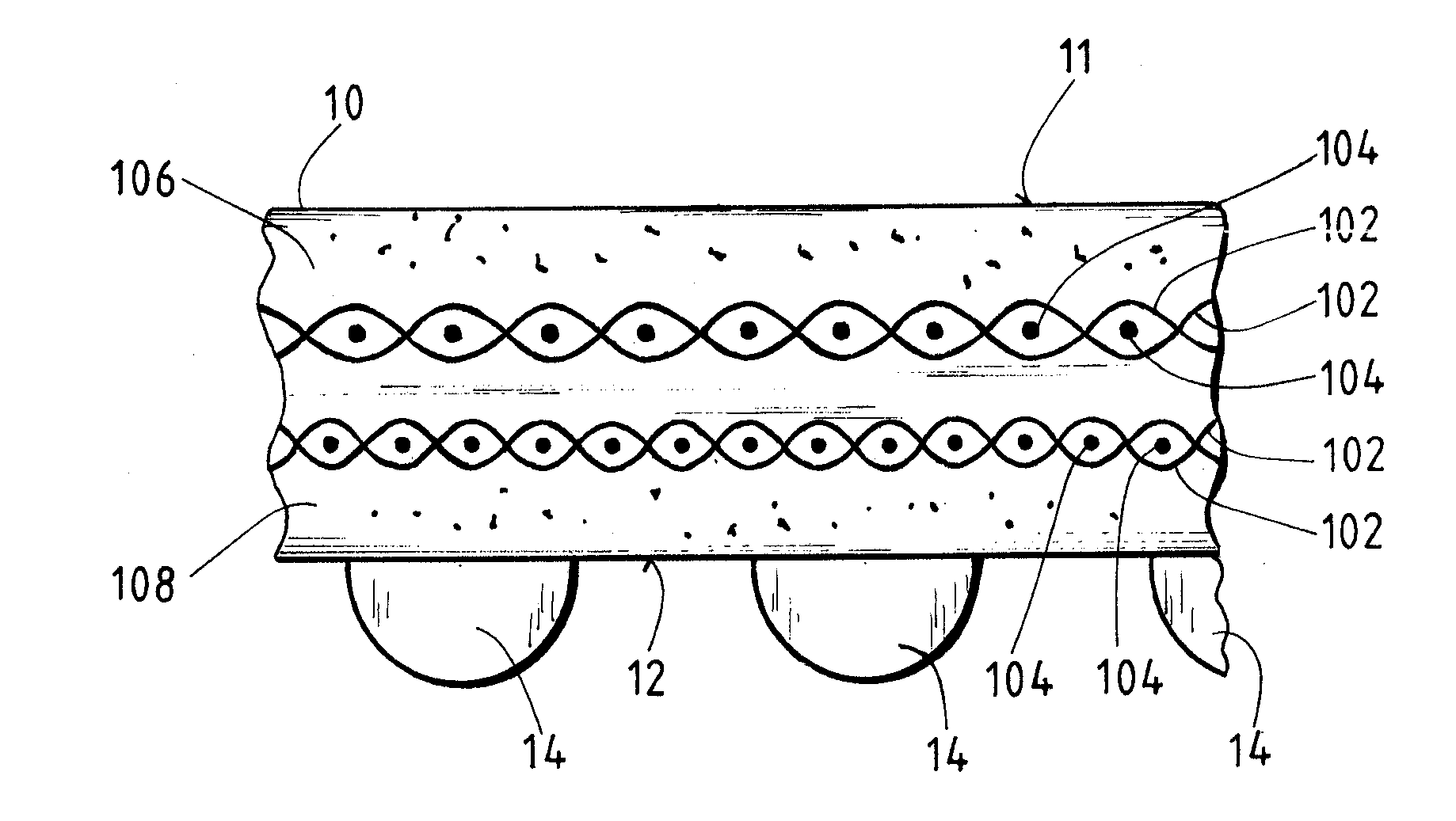

[0050] exist figure 2 A cross-secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com