Copper matrix composite material and preparation method thereof

A technology of copper-based composite materials and copper powder, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of increased thermal expansion coefficient of plates, unoptimized rolling process, low thermal expansion coefficient, etc., and achieve high tensile strength and hardness, improve the powder mixing effect, and the effect of good low expansion characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

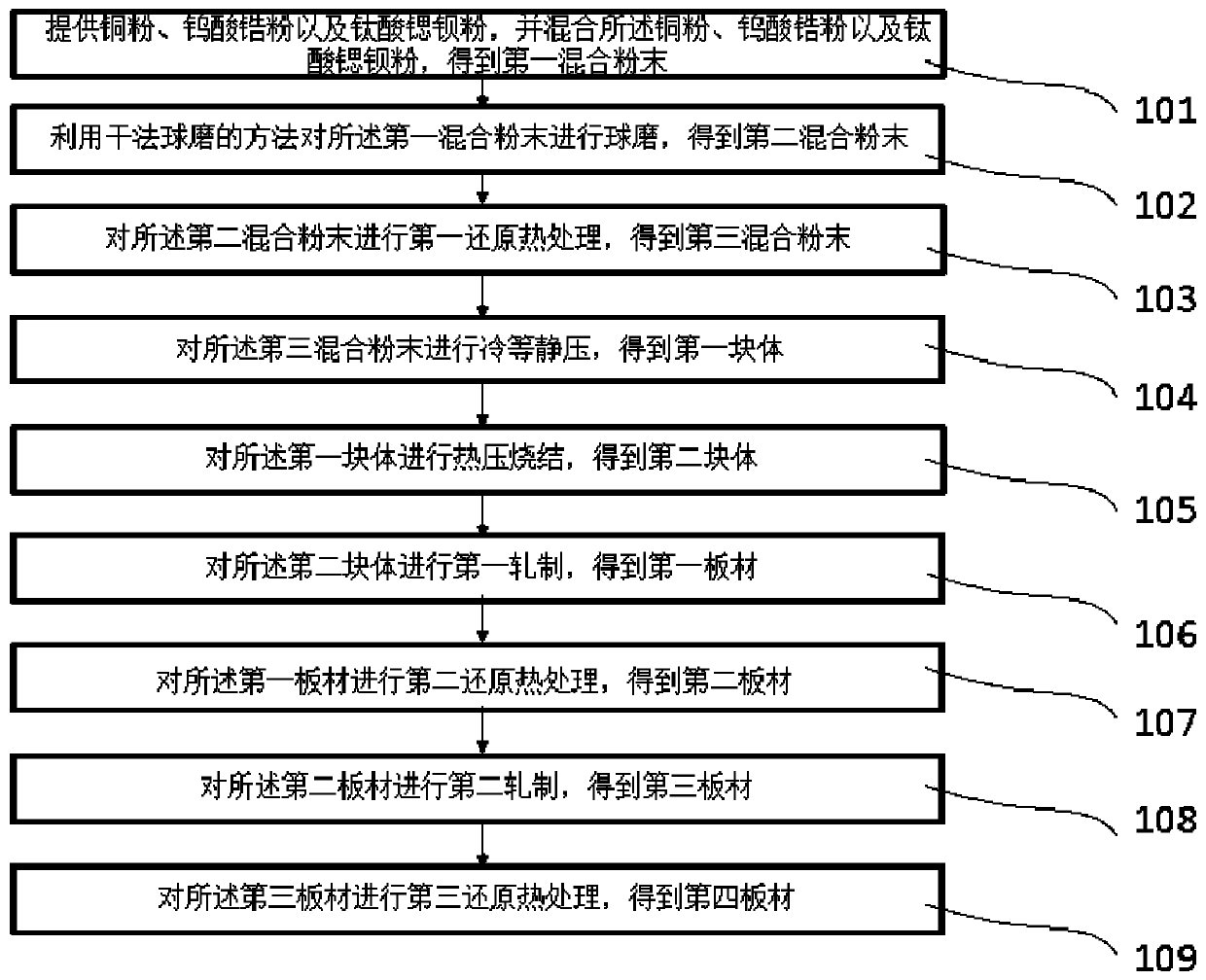

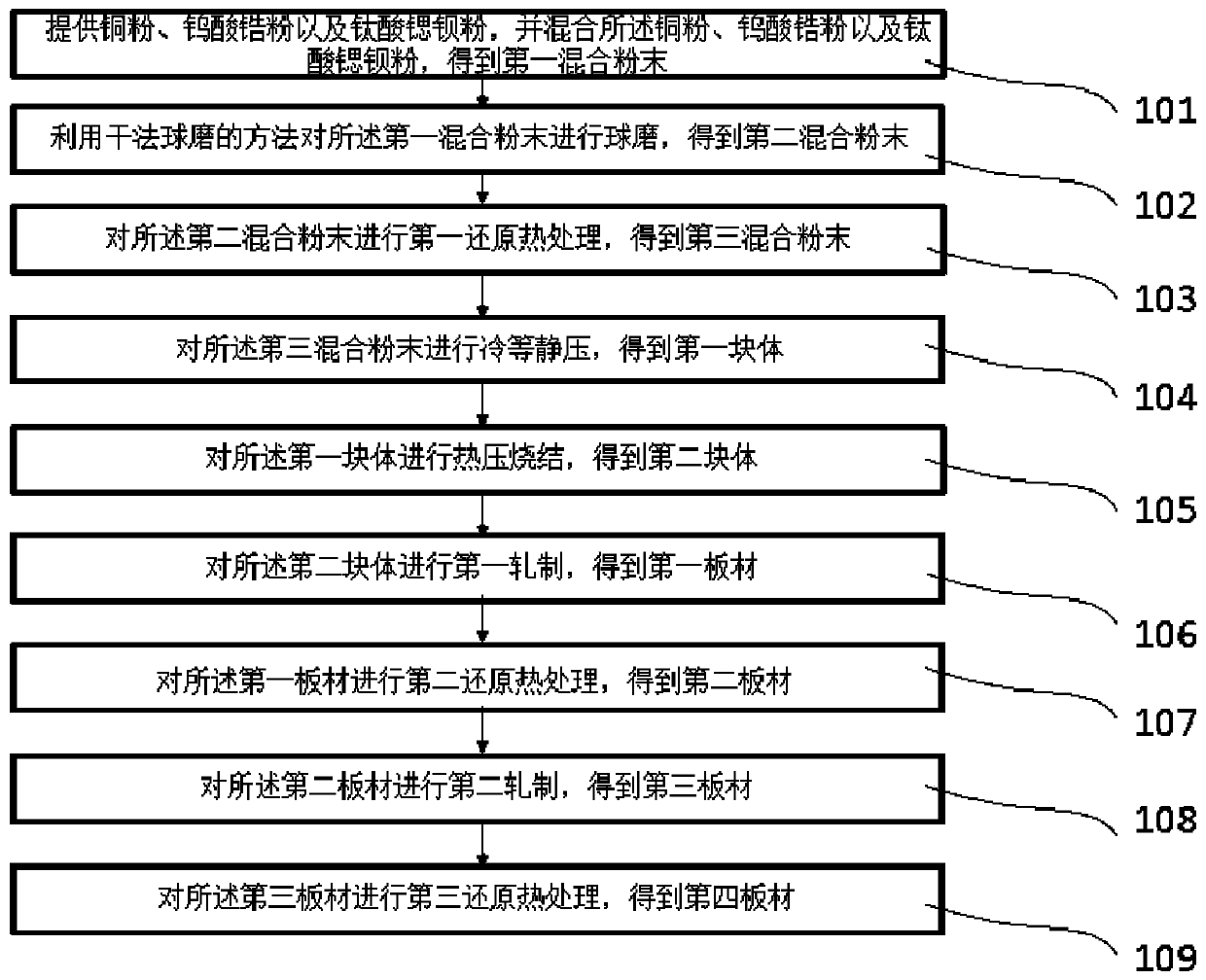

Method used

Image

Examples

Embodiment 1

[0021] The copper-based composite material is prepared as follows: provide copper powder, zirconium tungstate powder and strontium barium titanate powder, and mix copper powder, zirconium tungstate powder and strontium barium titanate powder to obtain the first mixed powder; use dry ball milling The method carries out ball milling to the first mixed powder, obtains the second mixed powder, and the rotating speed of the ball mill is 1000 rpm, and the ball milling time is 5 hours; Carries out the first reduction heat treatment to the second mixed powder, obtains the 3rd mixed powder, the first reduction The heat treatment atmosphere is hydrogen, the reduction heat treatment time is 25min, and the temperature is 450°C; the third mixed powder is subjected to cold isostatic pressing to obtain the first block; the first block is hot-pressed and sintered to obtain the second block; and The second block is rolled. The volume of the zirconium tungstate powder accounts for 20% of the vo...

Embodiment 2

[0023] The copper-based composite material is prepared as follows: provide copper powder, zirconium tungstate powder and strontium barium titanate powder, and mix copper powder, zirconium tungstate powder and strontium barium titanate powder to obtain the first mixed powder; use dry ball milling The method carries out ball milling to the first mixed powder, obtains the second mixed powder, and the rotating speed of the ball mill is 1000 rpm, and the ball milling time is 4 hours; Carries out the first reduction heat treatment to the second mixed powder, obtains the 3rd mixed powder, the first reduced The heat treatment atmosphere is hydrogen, the reduction heat treatment time is 25min, and the temperature is 450°C; the third mixed powder is subjected to cold isostatic pressing to obtain the first block; the first block is hot-pressed and sintered to obtain the second block; and The second block is rolled. The volume of the zirconium tungstate powder accounts for 20% of the volu...

Embodiment 3

[0025]The copper-based composite material is prepared as follows: provide copper powder, zirconium tungstate powder and strontium barium titanate powder, and mix copper powder, zirconium tungstate powder and strontium barium titanate powder to obtain the first mixed powder; use dry ball milling The method carries out ball milling to the first mixed powder, obtains the second mixed powder, and the rotating speed of the ball mill is 800 rpm, and the ball milling time is 6 hours; Carries out the first reduction heat treatment to the second mixed powder, obtains the 3rd mixed powder, the first reduced The heat treatment atmosphere is hydrogen, the reduction heat treatment time is 20 minutes, and the temperature is 500° C.; performing cold isostatic pressing on the third mixed powder to obtain the first block; performing hot pressing and sintering on the first block to obtain the second block; and The second block is rolled. The volume of the zirconium tungstate powder accounts for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com