Thermosetting epoxy resin composition

A technology of resin composition and epoxy resin, which is applied in the field of epoxy resin laminates, can solve the problems of high hardness, poor drilling quality, inconvenient use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8

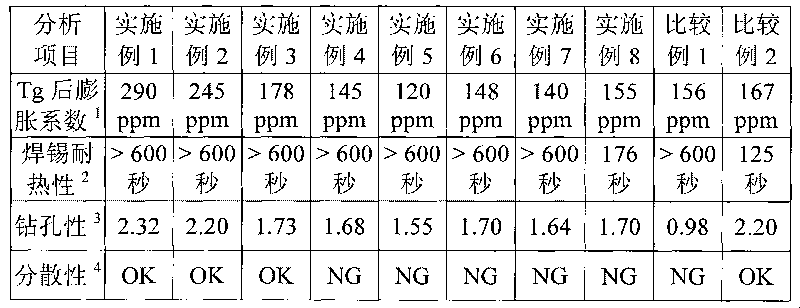

[0049] In embodiments 1 to 8, epoxy resin A, epoxy resin B, hardener A or hardener B and accelerators of the same proportion are used, but modified silicon dioxide of different proportions is added (Bao Lin company, product code G2C ), its formula composition is shown in Table 1, and utilizes acetone to be modulated into the thermosetting epoxy resin varnish that makes laminated board use, and wherein solid content accounts for 75%.

[0050] Prepare epoxy resin laminates by known methods, impregnate 7628 glass fiber cloth with the above-mentioned varnish resin solution, and then dry it at a temperature of 170°C (impregnation machine temperature) for several minutes, adjust and control the drying time to adjust the pre-drying The melt viscosity of the impregnated body is 4000-10000 poise. Finally, 4 pieces of film are stacked between two pieces of 35μm thick copper foil, at 25kg / cm 2 Under pressure, control the temperature and time of heating up, and after hot pressing, a lamin...

Embodiment 9~11

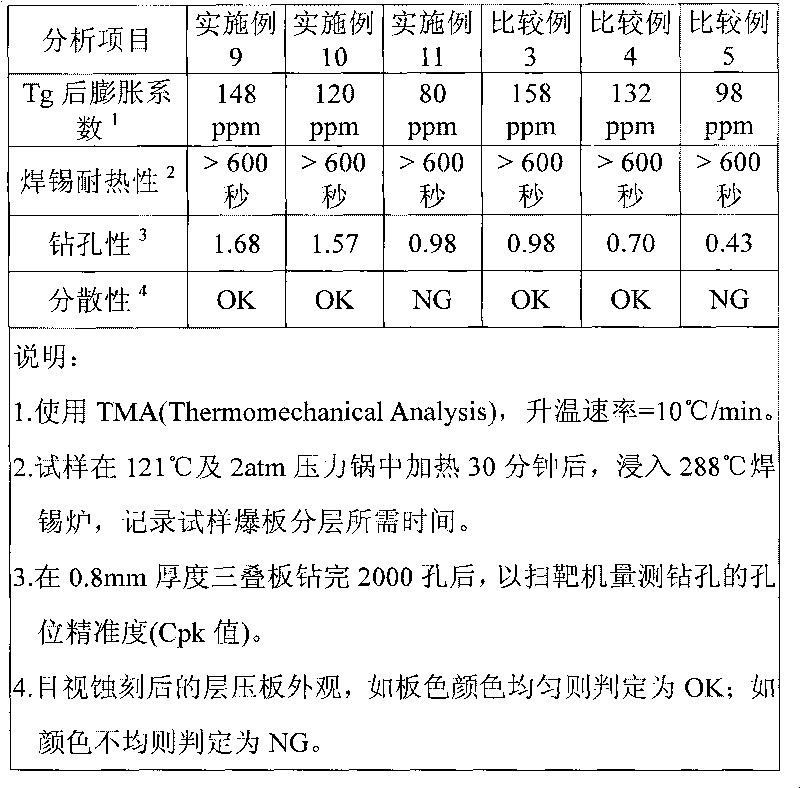

[0054] The formula composition is shown in Table 2. Embodiments 9-11 use the same proportion of epoxy resin A, epoxy resin B, hardener A and accelerator, and add 121PHR to 282.2PHR surface-treated modified silica filling material ( Baolin Company, product code name G2CARI), and utilize acetone to modulate into the thermosetting epoxy resin varnish that makes laminated board use, and wherein solid content accounts for 75%; Utilize again and embodiment 1~8 prepare laminated board identical method to prepare laminated board.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com