A kind of method for preparing tin-carbon lithium ion negative electrode material

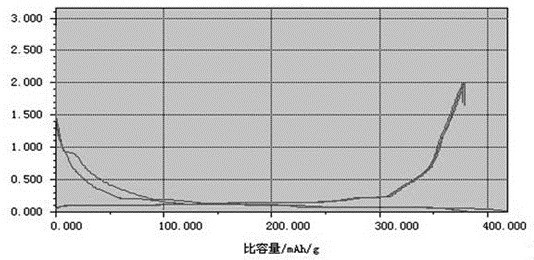

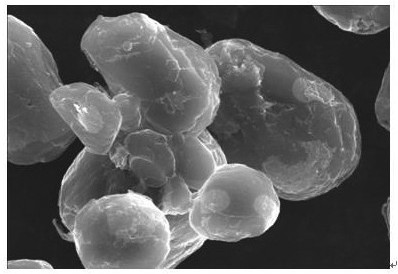

A negative electrode material and lithium ion technology, which is applied in the field of preparing tin-carbon lithium ion negative electrode materials, can solve problems such as deformation and cracking of electrode materials, poor cycle performance, and failure, and achieve the effects of reducing expansion characteristics, improving surface defects, and shortening the time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A method for preparing a tin-carbon lithium ion negative electrode material, comprising the following steps:

[0024] (1) Doping modification of tin dioxide: Weigh a certain weight of nano tin dioxide and cuprous oxide at a ratio of 100:30 and mix them by dry ball milling for 1 hour; then place them in an atmosphere furnace for carbothermal reduction, Under protection, the temperature was raised at 5°C / min to 800°C for 2 hours at a constant temperature; cooled to room temperature, a tin dioxide modified product was obtained.

[0025] (2) Composite granulation of tin dioxide modified product and graphite: sieve the tin dioxide modified product with 400 meshes, take the undersize material and mix with graphite, asphalt and phenolic resin in proportion with a V-shaped mixer at 25Hz 1h, the ratio is graphite: tin dioxide modified product: pitch: phenolic resin = 100: 15: 10: 5; put the mixture into a molding machine for briquetting at 18MPa, and then put the molding materia...

Embodiment 2

[0030] A method for preparing a tin-carbon lithium ion negative electrode material, comprising the following steps:

[0031] (1) Doping modification of tin dioxide: Weigh a certain weight of nano tin dioxide and cuprous oxide in a ratio of 100:10 for dry ball milling and mixing for 1 hour; then place in an atmosphere furnace for carbothermal reduction, Under protection, the temperature was raised at 5°C / min to 700°C for 2 hours, and then cooled to room temperature to obtain a tin dioxide modified product.

[0032] (2) Composite granulation of tin dioxide modified product and graphite: sieve the tin dioxide modified product with 400 meshes, take the undersize material and mix with graphite, asphalt and phenolic resin in proportion with a V-shaped mixer at 25Hz 1h, the ratio is graphite: tin dioxide modified product: pitch: phenolic resin = 100: 15: 5: 3; put the mixture into a molding machine for briquetting at 15MPa, and then put the molding material into the roasting chamber ...

Embodiment 3

[0036] A method for preparing a tin-carbon lithium ion negative electrode material, comprising the following steps:

[0037] (1) Doping modification of tin dioxide: Weigh a certain weight of nano-tin dioxide and cuprous oxide at a ratio of 100:50 and mix them by dry ball milling for 1 hour; then place them in an atmosphere furnace for carbothermal reduction, Under protection, the temperature was raised at 5°C / min to 950°C for 2 hours, then cooled to room temperature to obtain a tin dioxide modified product.

[0038] (2) Composite granulation of tin dioxide modified product and graphite: sieve the tin dioxide modified product with 400 meshes, take the undersize material and mix with graphite, asphalt and phenolic resin in proportion with a V-shaped mixer at 25Hz 1h, the ratio is graphite: tin dioxide modified product: pitch: phenolic resin = 100: 15: 15: 12; put the mixture into a molding machine for briquetting at 19MPa, and then put the molding material into the roasting cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com