Fiber-reinforced composite resin composition, and adhesive and sealing agent

一种纤维增强复合、树脂组合物的技术,应用在纤维素粘合剂、粘合剂类型、胶粘剂等方向,能够解决导热性未弄清、没有考虑密封剂、粘合剂或填充剂用途等问题,达到线热膨胀系数小的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

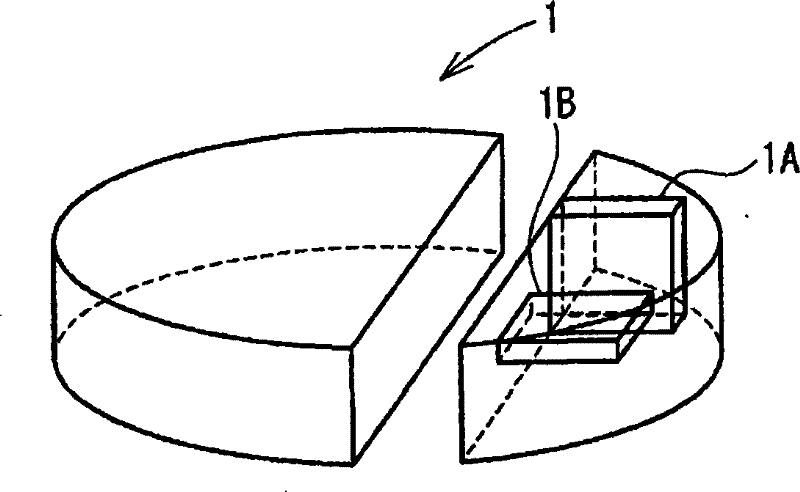

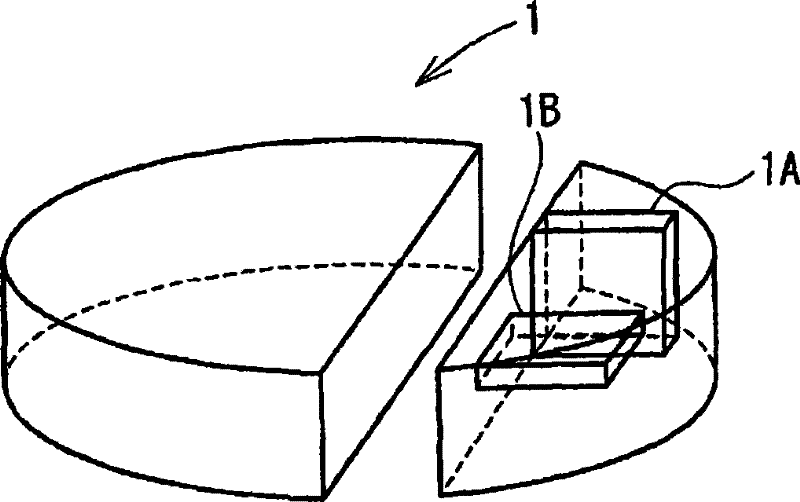

Image

Examples

Embodiment 1

[0193] Example 1: Fiber-reinforced composite resin composition containing BC

[0194] First, add the culture solution to the strain of acetic acid bacteria (FF-88) in the freeze-dried state, and let it stand for 1 week (25-30°C). Among the bacterial cellulose produced on the surface of the culture solution, select the one with a thicker thickness. Bacterial cellulose, take a small amount of the culture solution of the strain and add it to the new culture solution. Then, this culture solution was placed in a large incubator, and static culture was performed at 25 to 30° C. for 7 to 30 days. As a culture solution, 2% by weight of glucose, 0.5% by weight of yeast extract for bacteria, 0.5% by weight of peptone for bacteria, 0.27% by weight of disodium hydrogen phosphate, 0.115% by weight of citric acid, and 0.1% by weight of magnesium sulfate heptahydrate were used. Hydrochloric acid to adjust pH to 5.0 aqueous solution (SH medium).

[0195]The thus-produced aqueous bacterial c...

Embodiment 2

[0198] Example 2: Fiber-reinforced composite resin composition containing Nano MFC from pulp

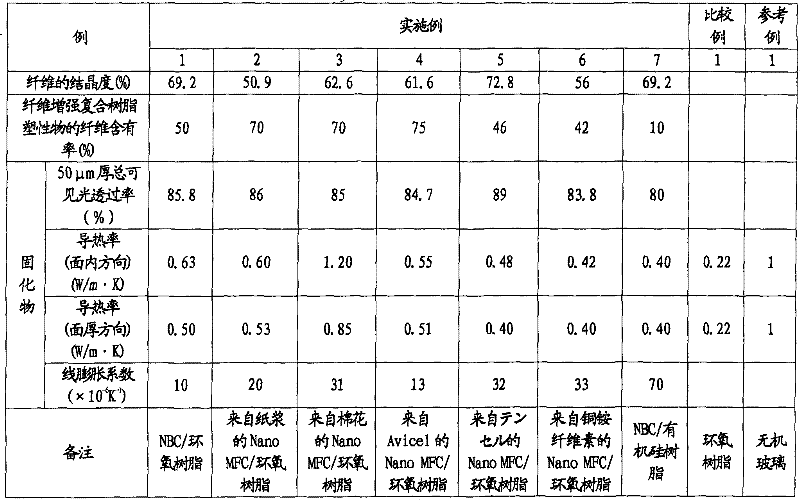

[0199] In addition to fully stirring microfibrillated cellulose in water: MFC (processed by a high-pressure homogenizer to microfibrillate coniferous kraft pulp (NBKP) with an average fiber diameter of 1 μm), prepare 7 kg of 1 wt % concentration Except for the aqueous suspension, in the same manner as in Example 1, the epoxy resin was impregnated to manufacture the fiber-reinforced composite resin composition of the present invention in which the Nano MFCs were randomly oriented. For the fiber-reinforced composite resin composition and curing The product was evaluated in the same manner as in Example 1, and the results are shown in Table 1.

Embodiment 3

[0200] Example 3: Fiber Reinforced Composite Resin Composition Containing NanoMFC from Cotton

[0201] Cotton (absorbent cotton) was used instead of pulp, and epoxy resin was impregnated in the same manner as in Example 1 to manufacture a fiber-reinforced composite resin composition of the present invention in which Nano MFCs were randomly oriented in the composition. For this fiber-reinforced composite resin composition The product and the cured product were evaluated in the same manner as in Example 1, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com