Preparation method and preparation system of insoluble sulfur

A preparation system, sulfur technology, applied in the direction of sulfur preparation/purification, etc., can solve the problems of complex operation process, poor thermal stability of insoluble sulfur, low yield, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

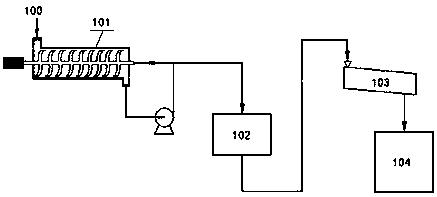

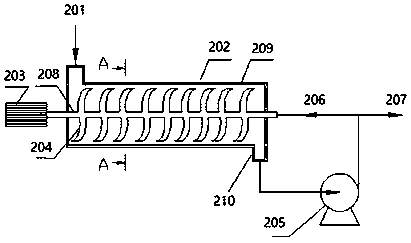

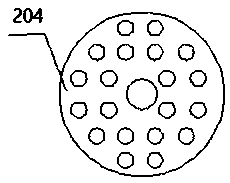

[0089] 4 tons / hour of liquid sulfur 100 is preheated to 120°C and enters the polymerization kettle. The amount of initiator added to the polymerization kettle is 0.15wt% of the amount of liquid sulfur added. The sulfur is heated to 255°C through the jacket in the polymerization kettle for polymerization. And keep the temperature for 30 minutes; the polymerized sulfur is continuously fed in and out of the material under the action of the rake-type stirring paddle, and the discharge is pressurized by the gear pump, 60wt% of the material is discharged to the quenching device, and 40wt% of the material is returned to the hollow shaft of the rake-type stirring paddle with the Feed mix. After the liquid sulfur is polymerized, it is granulated and quenched in the quenching device. The granulation is 2 mm in diameter. , FeCl 3 Adding amount is 0.3% (mass fraction) of sulfur mass, HNO 3 The amount added is 2% (mass fraction) of the mass of sulfur. The quenched crude product is promo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com