Eccentric colorful medium-sized granulator

A granulator and eccentric technology, applied in the field of eccentric colorful medium-sized granulators, can solve the problems of low granulation efficiency, constant shaking force, inability to continuously produce, etc., to avoid low labor efficiency and uniform granulation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The implementation of the present application will be described in detail below with reference to the accompanying drawings and examples, so as to fully understand and implement the implementation process of how the present application uses technical means to solve technical problems and achieve technical effects.

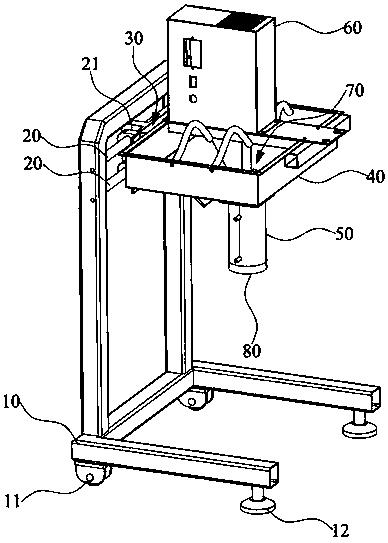

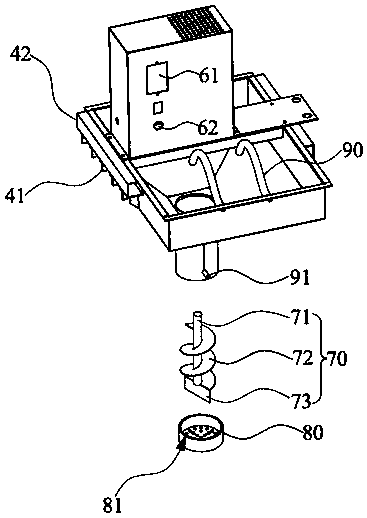

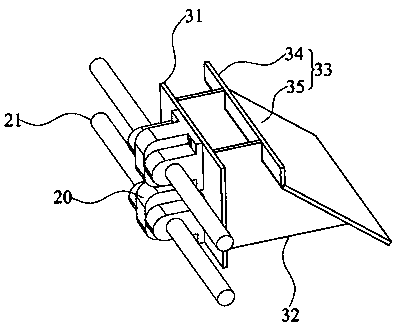

[0026] Please refer to figure 1 , figure 1 It is a three-dimensional view of the eccentric colorful medium-sized granulator of the embodiment of the application. As shown in the figure, an eccentric colorful medium-sized granulator includes a frame 10, and the frame 10 is provided with two guide rods 20 at intervals; sliders 21 respectively sleeved on the guide rods 20; Resist the material frame 30; buckle in the feed bin 40 of the feed rack 30; be arranged under the feed bin 40 and communicate with the feed pipe 50 of the feed bin 40; set up the cabinet 60 in the feed bin 40; by the cabinet 60 The screw conveying granulation assembly 70 that drives and gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com