Microcapsule granulation device

A granulation device and granulation technology, applied in the direction of microcapsule preparation, microsphere preparation, etc., can solve the problems of unsatisfactory assembly line production and irregular shape of product particles, and achieve good granulation effect, light weight and reasonable design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

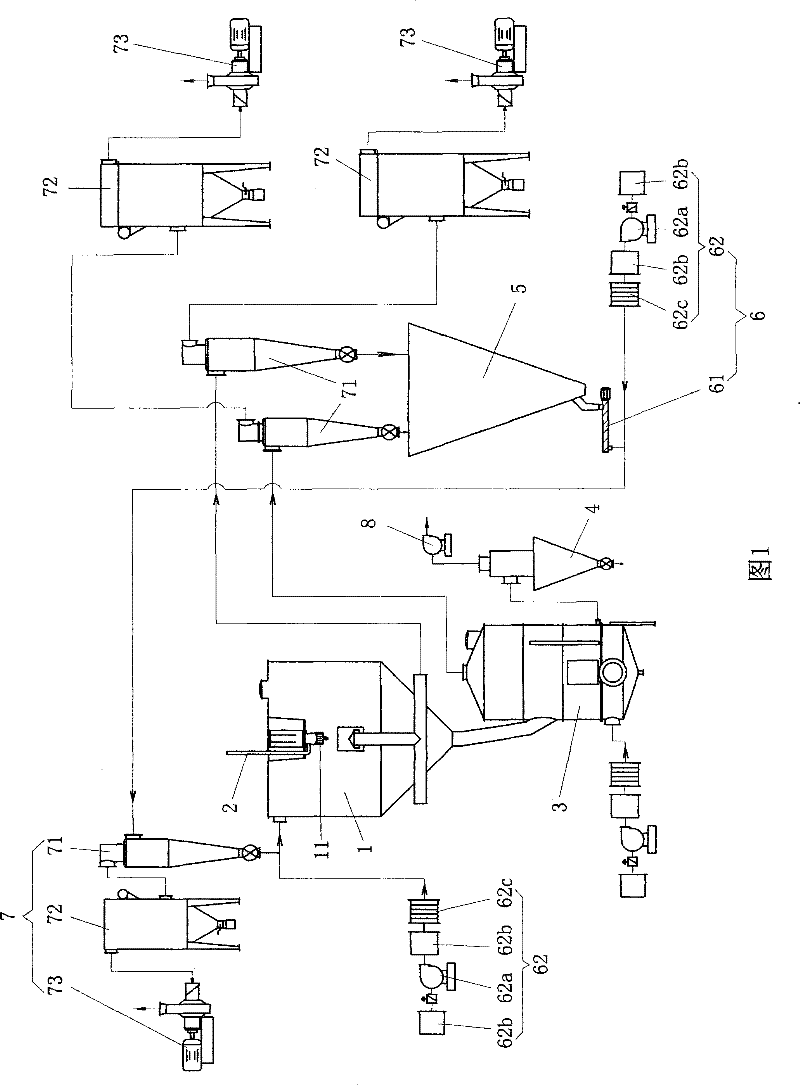

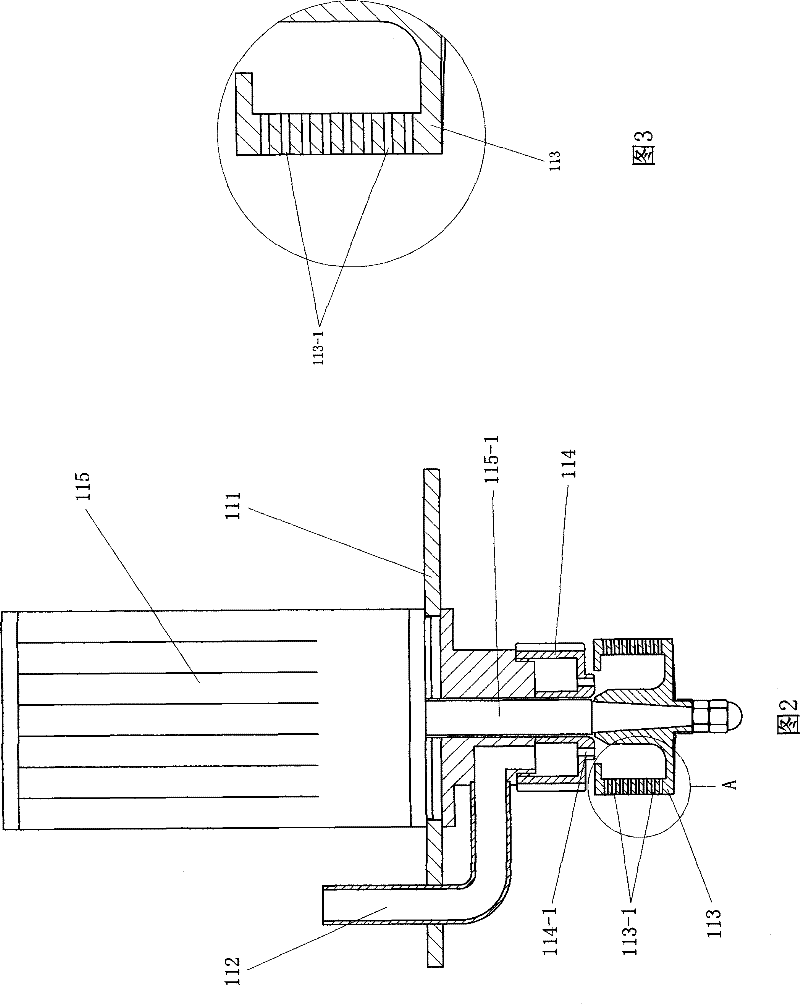

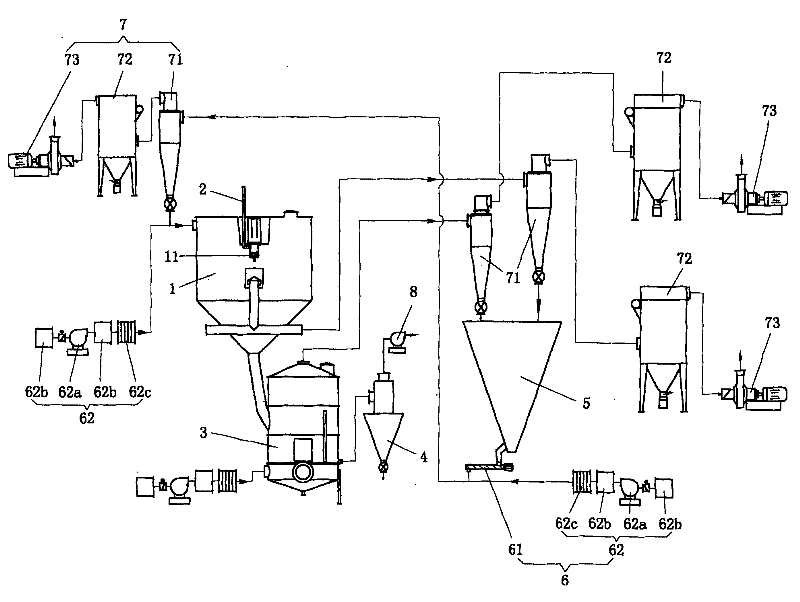

[0039] see figure 1 , The present invention has a prilling tower 1, a slurry supply pipeline 2, a drying fluidized bed 3, and a finished product silo 4; there is a prilling head 11 above the prilling tower 1, and the slurry supply pipeline 2 is connected to the prilling head 11 The bottom of the prilling tower 1 is connected to the drying fluidized bed 3 through a pipeline, and the bottom of the drying fluidized bed 3 is connected to the finished product silo 4 through a pipeline; the microcapsule granulation device is also equipped with a coating auxiliary silo 5, and the coating auxiliary materials can be starch or Other corresponding auxiliary materials; the bottom of the coated auxiliary silo 5 is connected to the upper part of the prilling tower 1 through a pipe, and the top of the coated auxiliary silo 5 is respectively connected to the lower part of the prilling tower 1 and the top of the drying fluidized bed 3 through a pipe; 5 The pipe between the bottom and the upper p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com