Boiling drying granulating device

A technology of boiling dry granulation and granulator, which is applied in the directions of drying gas arrangement, drying of granular materials, and devices for making medicines into special physical or taking forms, etc. It is not very ideal, etc., to achieve the effect of protecting the operator, less dust flying, and simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

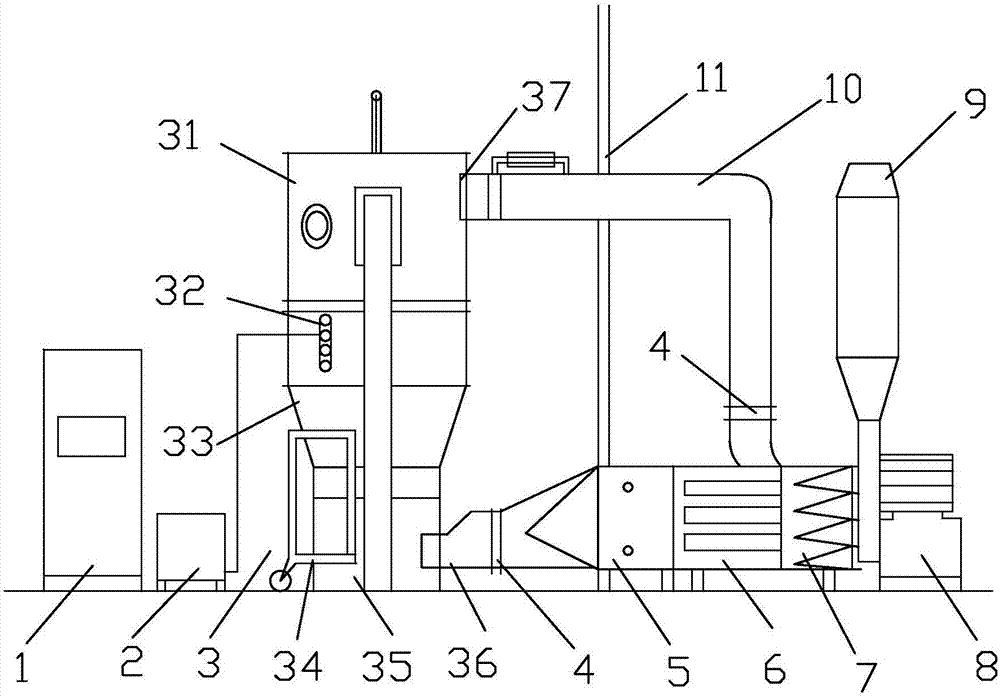

[0019] Such as figure 1 As shown, the fluidized drying granulation device of this embodiment includes a granulator 3, and the granulator 3 includes an upper top bin 31, a middle fluidized bed granulation bin 33 and a lower bottom bin 35, and the top bin 31, The fluidized bed granulation bin 33 and the bottom bin 35 are connected to each other and sealed to form a complete bin body. The side wall of the top bin 31 is provided with an air inlet 37, and the side wall of the bottom bin 35 is provided with an air inlet 36. The air inlet 36 is connected to the The steam heater 5 is in communication, and the air regulating valve 4 is arranged on the pipeline. The inlet of the steam heater 5 is connecte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com