Granulation device for straw recycling

A granulation device and straw technology, applied in the direction of raw material extrusion granulation, solid fuel, biofuel, etc., can solve the problems of low granulation efficiency, incomplete blanking, inconvenient use, etc., and achieve a large number of granules, Not easy to clog, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

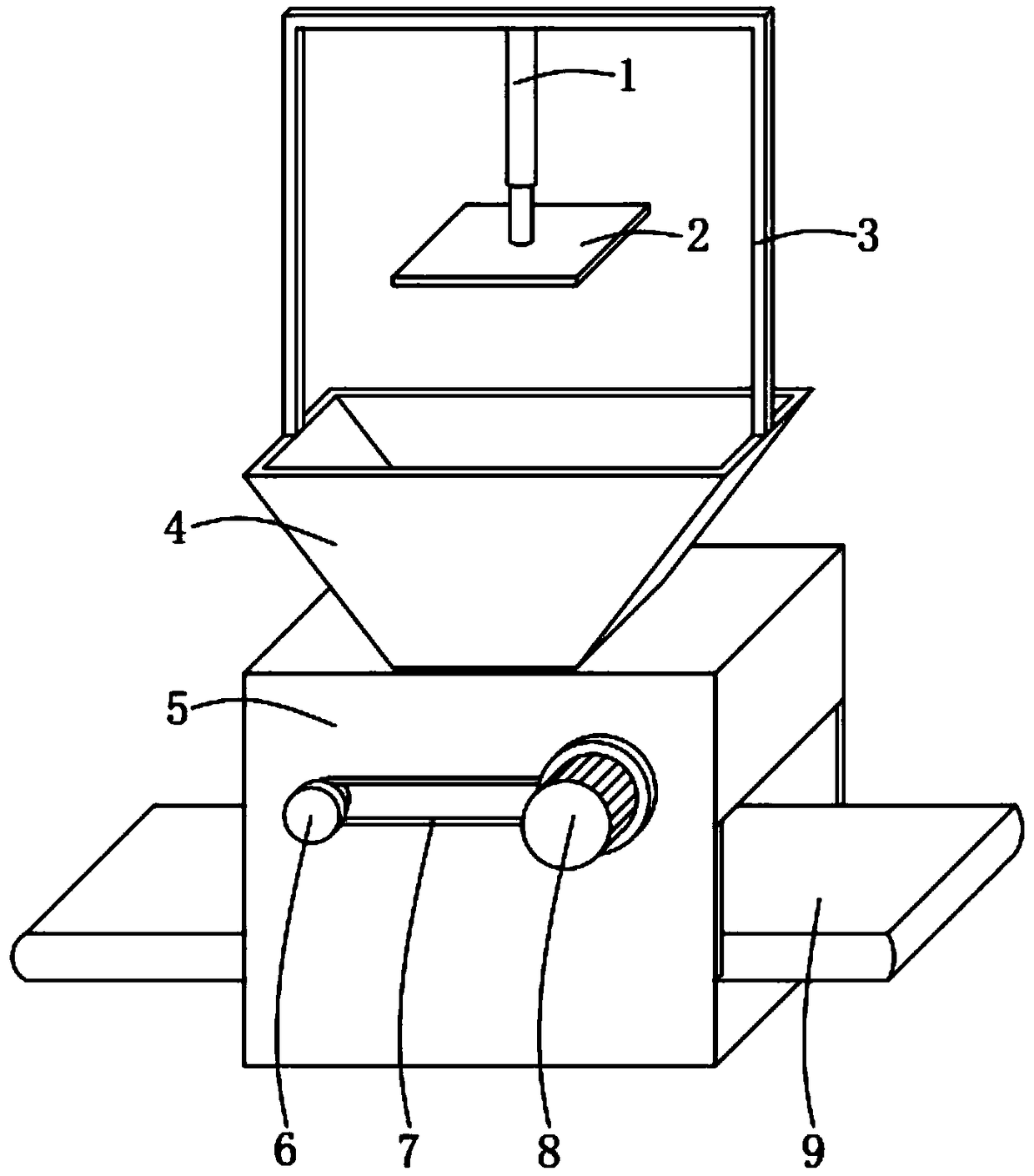

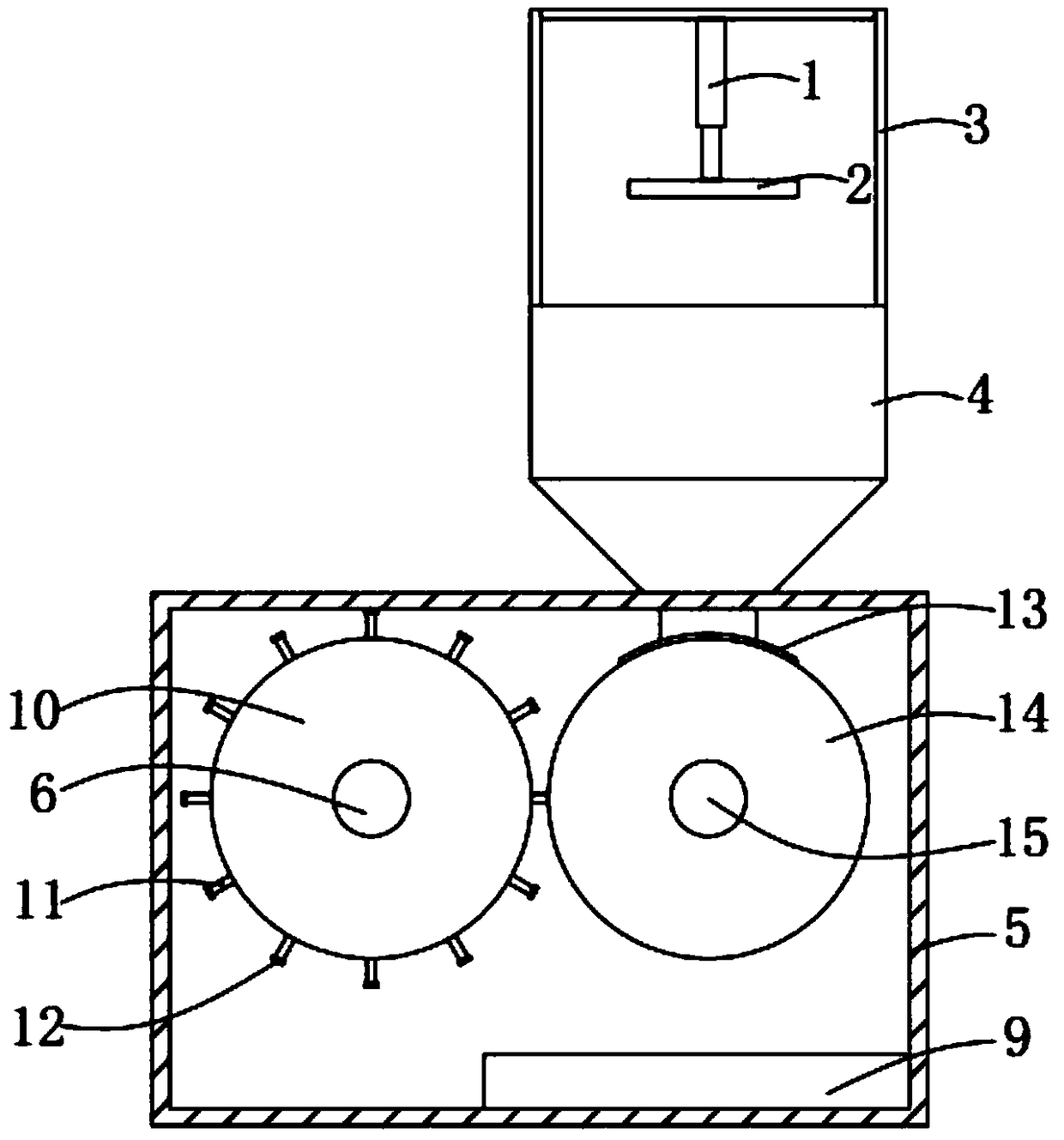

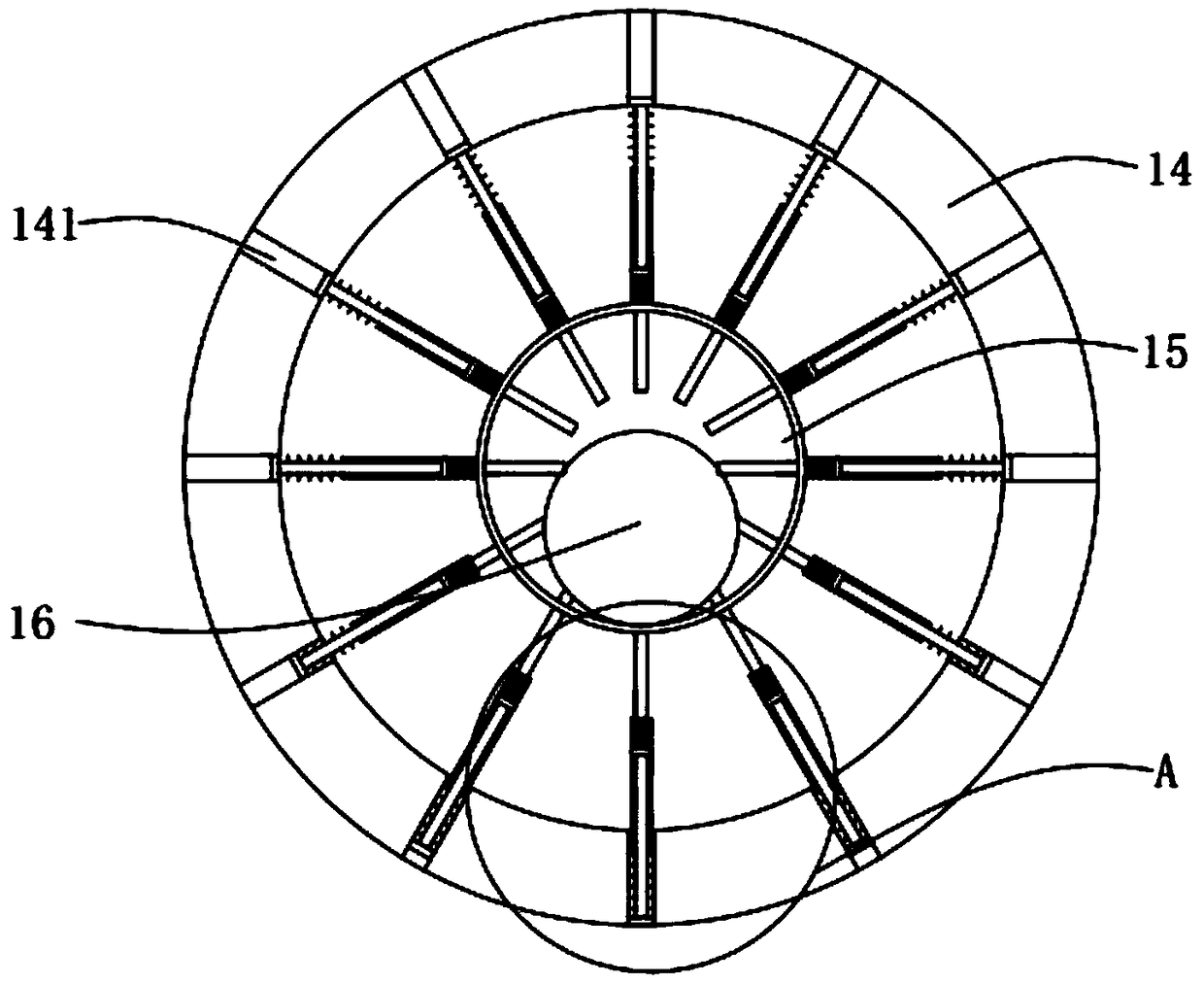

[0024] Such as Figure 1-5 As shown, a granulation device for straw recycling includes a charging part, a pressing part and a feeding part; the charging part includes a lower hopper 4, and a protective cover 13 is fixed at the bottom of the lower hopper 4, and the protective cover 13 is tight Lay the granulation roller 14; the protective cover 13 communicates with the lower hopper 4 and the granulation roller 14, and the outer side of the granulation roller 14 is equidistantly provided with several collecting holes 141; the pressing part includes the pressing wheel 10, and the outer side of the pressing wheel 10 Connecting rods 11 having the same number as the collection holes 141 are fixed in a circular array equidistantly, and the side of the connecting rods 11 is fixed with a pressing block 12; Rotating shaft 6; the end of the first rotating shaft 6 is connected to the second rotating shaft 15 by the belt 7, and the second rotating shaft 15 is connected to the motor 8; the ...

Embodiment 2

[0027] It includes a charging part, a pressing part and a feeding part; the charging part includes a lower hopper 4, the bottom of the lower hopper 4 is fixed with a protective cover 13, and the protective cover 13 is closely attached to the granulation roller 14; the protective cover 13 communicates with the lower hopper 4 and Granulation roller 14, and the outside equidistant of granulation roller 14 is provided with several collecting holes 141; Connecting rod 11, and the side portion of connecting rod 11 is fixed pressing block 12; Two rotating shafts 15, and the second rotating shaft 15 is connected to the motor 8; the blanking part includes a piston plate 23, the piston plate 23 is slidably connected to the inside of the collecting hole 141, and the side of the piston plate 23 is fixed to the second limit rod 20; The ends of the two limit rods 20 fix the first limit rod 17 through the stopper 19, and the second limit rod 20 and the first limit rod 17 are all slidably con...

Embodiment 3

[0030] It includes a charging part, a pressing part and a feeding part; the charging part includes a lower hopper 4, the bottom of the lower hopper 4 is fixed with a protective cover 13, and the protective cover 13 is closely attached to the granulation roller 14; the protective cover 13 communicates with the lower hopper 4 and Granulation roller 14, and the outside equidistant of granulation roller 14 is provided with several collecting holes 141; Connecting rod 11, and the side portion of connecting rod 11 is fixed pressing block 12; Two rotating shafts 15, and the second rotating shaft 15 is connected to the motor 8; the blanking part includes a piston plate 23, the piston plate 23 is slidably connected to the inside of the collecting hole 141, and the side of the piston plate 23 is fixed to the second limit rod 20; The ends of the two limit rods 20 fix the first limit rod 17 through the stopper 19, and the second limit rod 20 and the first limit rod 17 are all slidably con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com