Vertical drying-and-granulating integrated equipment and working method thereof

A vertical and granulation technology, which is applied to chemical instruments and methods, granulation in static tanks/tanks, dehydration/drying/thickened sludge treatment, etc., can solve the problems of high energy consumption and fixed connections on the top of the shell 1. The motor, the output end of the motor is fixedly connected to the transmission shaft, the left end of the transmission shaft is fixedly connected to the active bevel gear, the upper part of the heating box is fixedly connected to the fixed connecting rod, the middle part of the fixed connecting rod is connected to the longitudinal rotating shaft, and the top of the longitudinal rotating shaft is fixedly connected to the The driven bevel gear, the driven bevel gear is meshed with the driving bevel gear, the bottom of the longitudinal shaft is fixedly connected, and the thermal efficiency is low, so as to achieve the effect of high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with embodiment the method of the present invention is described in further detail. It should be noted that the protection scope of the present invention shall include but not be limited to the technical content disclosed in this embodiment.

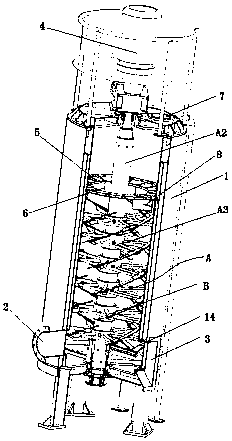

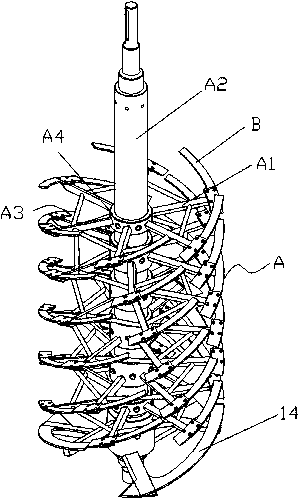

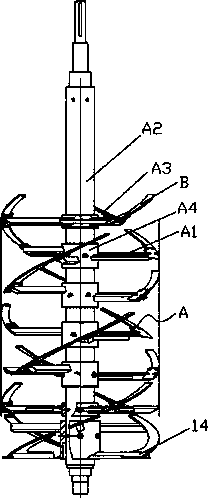

[0037]The vertical drying and granulation integrated equipment of the present invention includes a vertical tank body 1 and a cutter shaft assembly A arranged in the vertical tank body 1, and the cutter shaft assembly A is provided with discontinuous spiral ribbons. The blade B (or a blade with a helical surface in the shape of a broken or continuous belt), is provided with a cutting edge B1 on the lower edge K of each blade B, and each blade B is connected to the cutter shaft through a connecting rod A1 On the assembly A, the intermittent spiral ribbon shape means that the blades on the cutter shaft assembly A are discontinuous, that is, there is a gap in the middle.

[0038] The above-mentioned cutter shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com