Mobile steel refuge chamber

A technology of refuge chamber and steel body, applied in safety devices, mining equipment, earth-moving drilling, etc., can solve the problems of damage to the rescue cabin, inability to realize manual underground transportation, and no practical value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

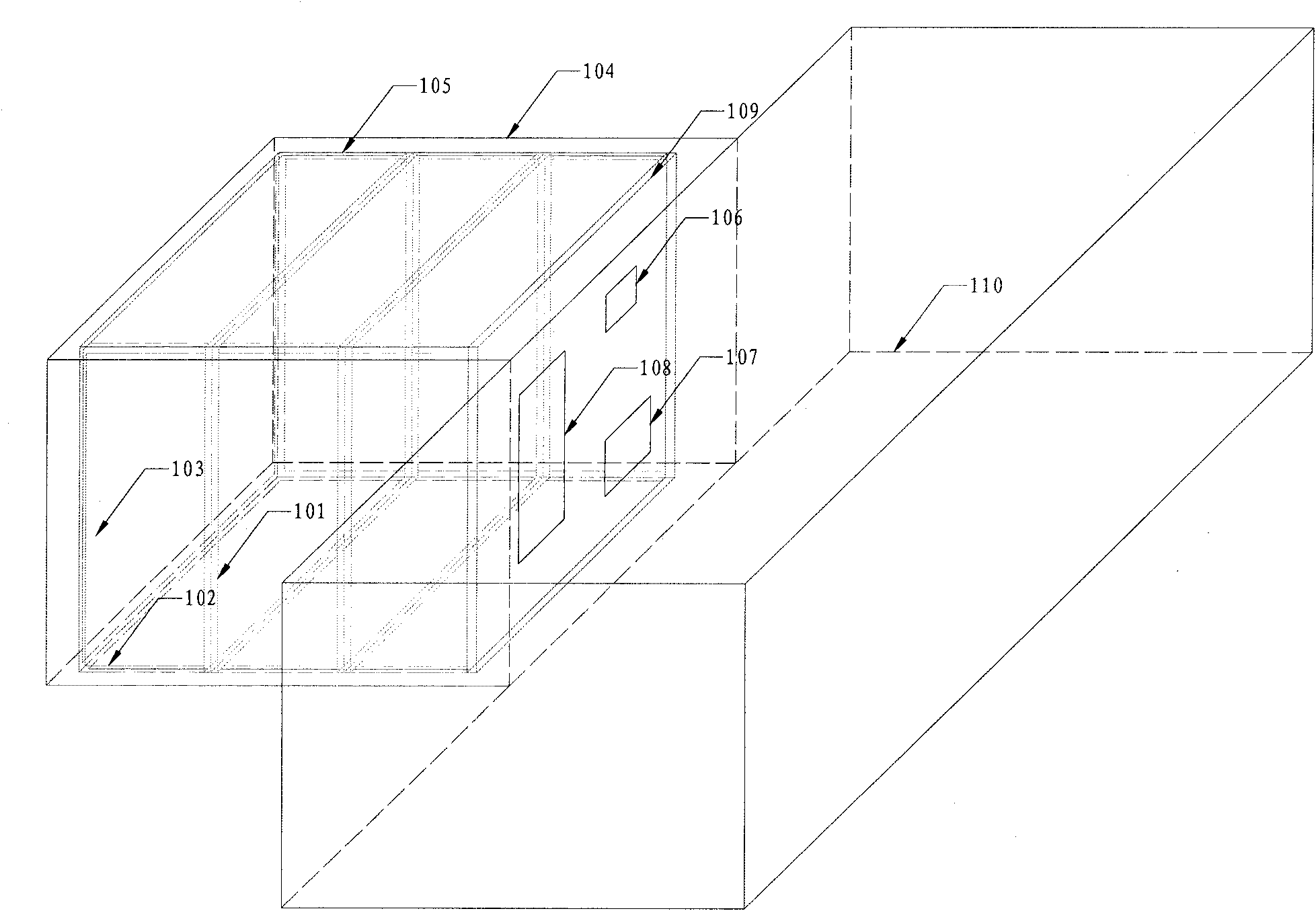

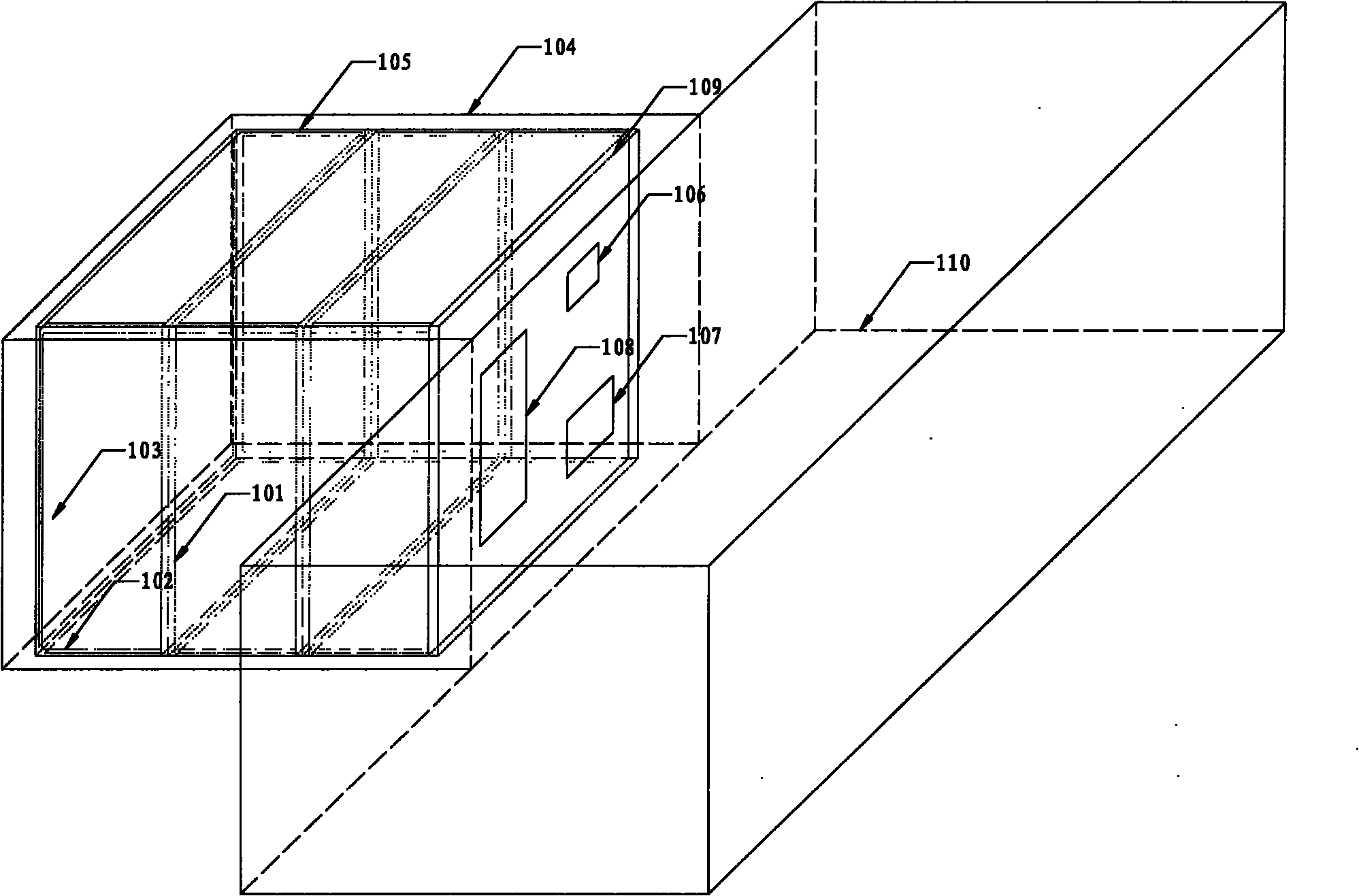

[0026] combine figure 1 , the product of the mobile steel refuge chamber provided by the present invention includes the following parts:

[0027] Within 1000m of the working face of the miners, select the roadway section with stable geological conditions (no rock burst, no gas outburst, no roof breakage, no large-scale deformation of the roadway, no uncontrollable floor drum, etc.), and the terrain is relatively high. Said this section roadway has flood natural living space), selects described reasonable roadway section 110 construction simple and easy refuge chamber 104 on the escape route.

[0028] Strengthen the support within the range of 5-20m near the simple refuge chamber 104 and the roadway 110, and there are no hidden dangers of disasters such as roof fall, sideways, and fire within the range.

[0029] In the simple refuge chamber 104, a detachable mobile steel refuge chamber lining 105 is installed, and the steel refuge chamber lining can be decomposed into small st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com