Field mounting method for test chamber

A technology of on-site installation and test cabin, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem of difficult installation of test cabins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

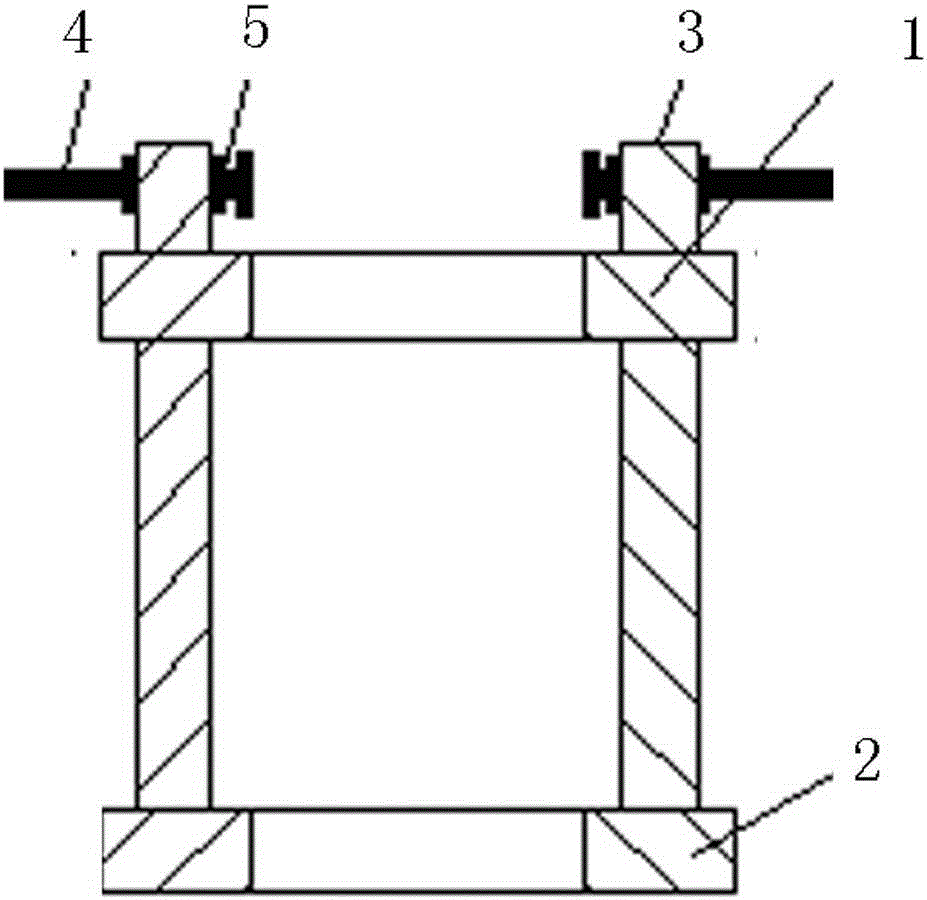

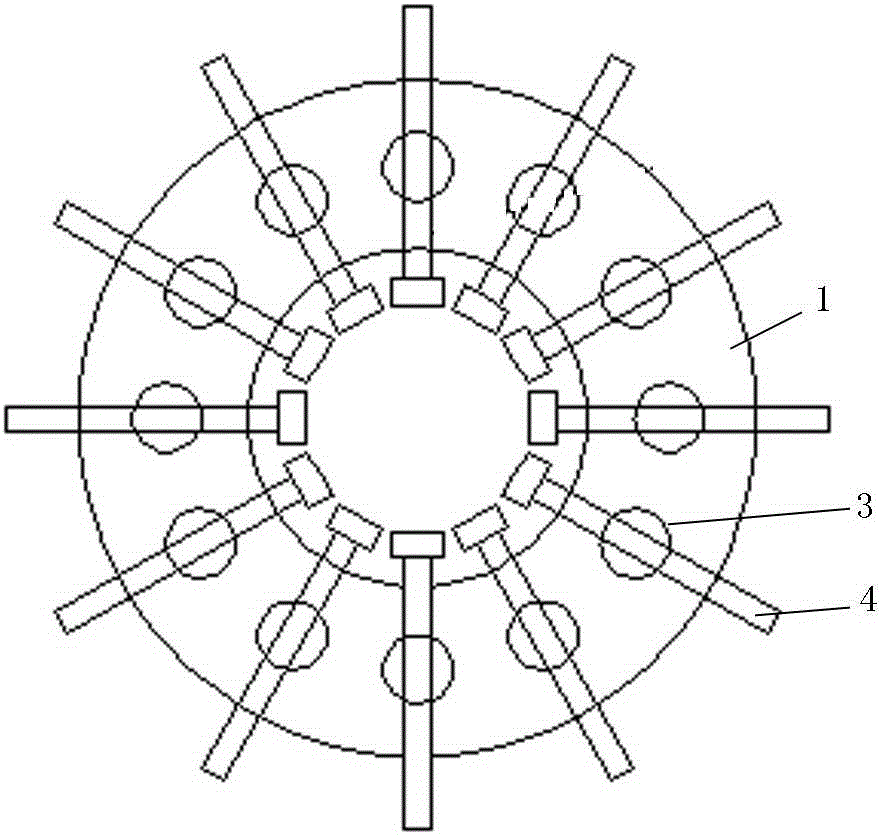

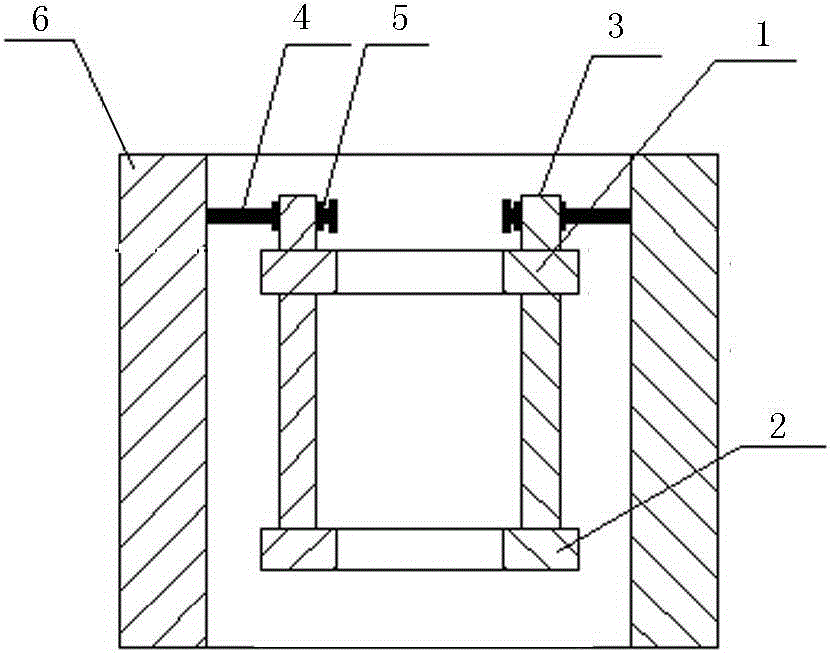

[0032] Taking the 8000mm inner diameter of the barrel section cylinder as an example, the installation method of the present invention includes the following steps:

[0033] Step 1 Picking materials: pick up the material Q345R, δ=52mm plate, the surface of the material should not have defects such as cracks, delamination, folding, and slag inclusions; the surface defects of the plate are allowed to be removed and ground, and the ground part should be smoothly transitioned;

[0034] Step 2 blanking: cutting the above-mentioned sheet by gas cutting, removing the surface slag and oxides generated during gas cutting and cutting, and grinding the periphery to be smooth, without cracks or slag inclusions on the end surface;

[0035] Step 3 Edge planing: the surface of the groove of the above-mentioned sheet shall have no defects, and the roughness shall not be lower than 25;

[0036] Step 4 Welding panel: the above-mentioned panels are laid out according to the process, and the pane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com