Sulfur-containing gas desulfurization device system and method

A desulfurization device and gas technology, applied in the field of environmental engineering, can solve the problems of enhanced chemical oxidation of sulfides, decreased cell activity and desulfurization performance, and weakened organic sulfur inhibition, so as to reduce the formation of S2O32- and SO42- and achieve good application. Prospect, the effect of increasing the generation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

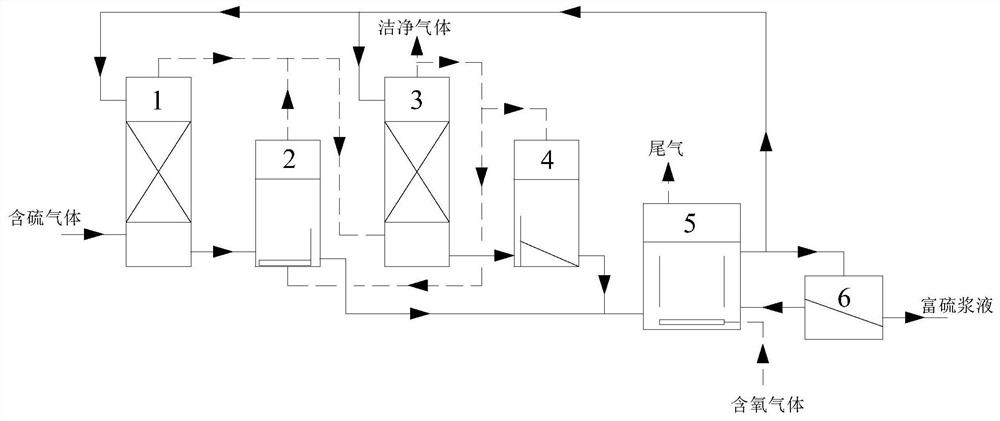

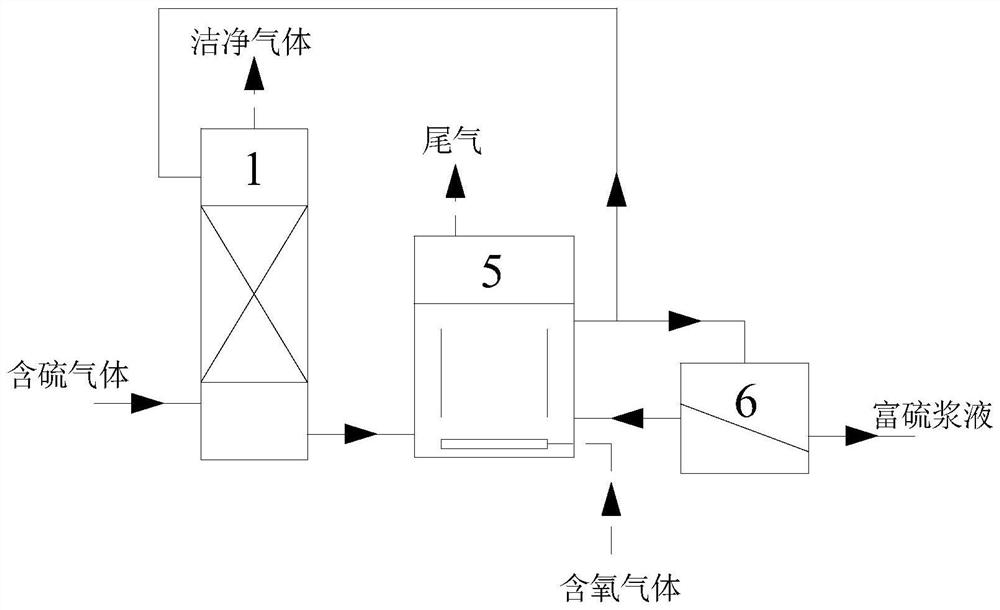

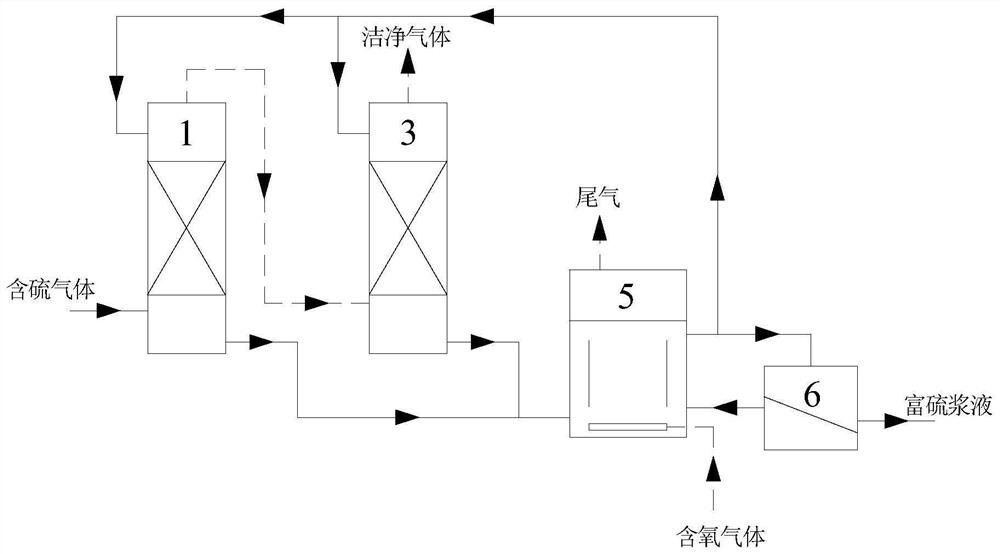

[0091] This embodiment provides a sulfur-containing gas desulfurization device system, the structural diagram of the sulfur-containing gas desulfurization device system is as follows figure 1 As shown, it includes biological purification tower, deep adsorption tower, tail gas removal tower, anaerobic conversion tower, biological regeneration tower and sulfur collection tower.

[0092] The liquid outlet of the biological purification tower is connected with the liquid inlet of the deep adsorption tower.

[0093] The liquid outlet of the tail gas removal tower is connected with the liquid inlet of the anaerobic conversion tower.

[0094] The liquid outlet of the deep adsorption tower and the liquid outlet of the anaerobic conversion tower are respectively independently connected with the liquid inlet of the biological regeneration tower.

[0095] The liquid outlet of the biological regeneration tower is independently connected with the liquid inlets of the biological purificati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com