Device and method for deeply denitrifying landfill leachate through electrochemical coupling sulfur autotrophic denitrification system

A technology for landfill leachate and deep denitrification, which is applied in the field of landfill leachate deep denitrification device of electrochemically coupled sulfur autotrophic denitrification system, can solve the problem of affecting the denitrification efficiency of sulfur oxidizing bacteria, and the denitrification efficiency is difficult to be guaranteed and reduced. The pH of the reaction environment and other problems can achieve the effect of low sludge production, enhanced activity and enhanced effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

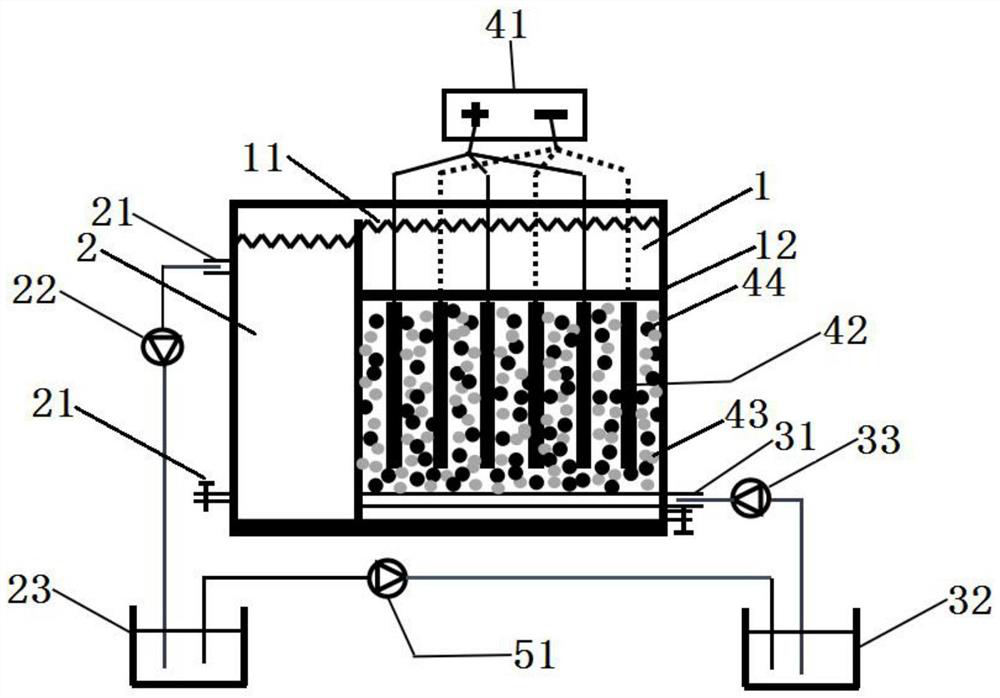

[0047] Example 1 A deep denitrification device for landfill leachate in an electrochemically coupled sulfur autotrophic denitrification system

[0048] like figure 1 As shown, the landfill leachate deep denitrification device adopts an upflow design, including a reactor main body, a water inlet system, a reaction system, an outlet water system and a circulation system. The material of the reactor main body is plexiglass, and the reactor The main body of the device is arranged into two parts, the reaction chamber 1 and the overflow area 2 from the vertical direction, the top of the reaction chamber 1 is provided with an overflow weir 11, and the inner upper wall of the reaction chamber 1 is provided with a support plate 12;

[0049] Described water inlet system comprises water inlet 31, water inlet tank 32, water inlet pump 33 and water inlet pipe, and described water inlet 31 is arranged on the bottom of reaction chamber 1, and described water inlet 31 place is provided with w...

Embodiment 2

[0054] Example 2 Establishment of deep denitrification method for landfill leachate in electrochemically coupled sulfur autotrophic denitrification system

[0055] On the basis of the deep denitrification device for landfill leachate in an electrochemically coupled sulfur autotrophic denitrification system in Example 1, a method for deep denitrification of landfill leachate in an electrochemically coupled sulfur autotrophic denitrification system is established. Specifically include the following steps:

[0056] (1) Microbial inoculation

[0057] To the electrochemically coupled sulfur autotrophic denitrification system landfill leachate deep denitrification device of embodiment 1, add the mud-water mixture of the sulfur autotrophic denitrification activated sludge whose initial sludge concentration is 6g MLSS / L, and the mud-water mixture passes through The water inlet pool 32 enters the reaction chamber 1, and then flows to the water outlet pool 23 through the overflow area ...

Embodiment 3

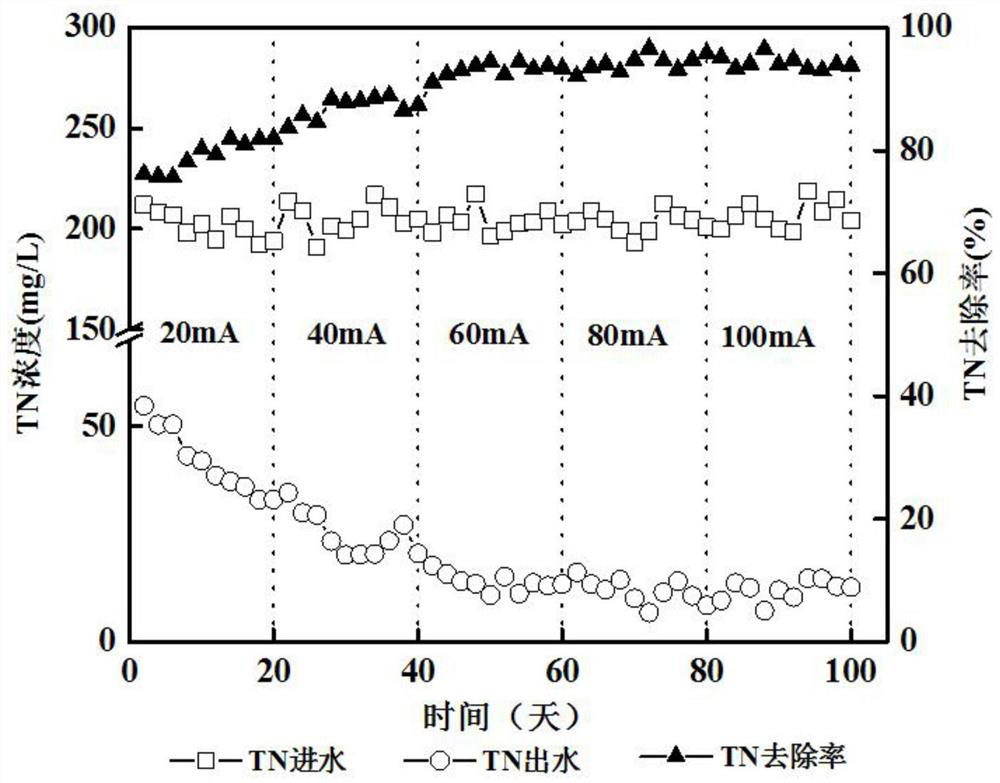

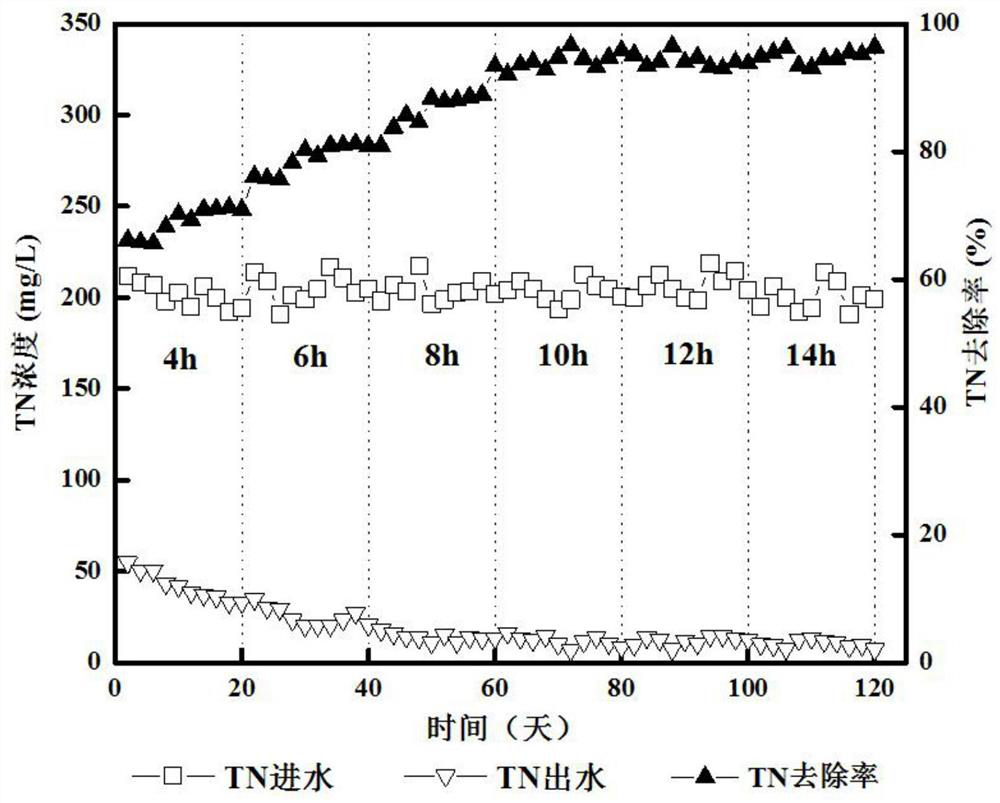

[0063] Example 3 Effect of Current Intensity on Application Effect of Electrochemical Coupled Sulfur Autotrophic Denitrification System Landfill Leachate Deep Denitrification Method

[0064] The deep denitrification method of landfill leachate in the electrochemically coupled sulfur autotrophic denitrification system established in Example 2 performs deep denitrification of landfill leachate at different current intensities, and explores the effect of different current intensities on reactor denitrification by adjusting the current intensity Influenced by the effect, set the current gradient to 20, 40, 60, 80, 100mA, and the reactor feed water is the landfill leachate effluent treated by the short-range nitrification + anammox secondary coupling process. The detailed water quality is shown in Table 1. Other operating conditions are set as follows: influent pH is 7.5-8.5, HRT (hydraulic retention time) is 12h, internal circulation is 4Q, reactor influent NO 3 - -N concentratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com