Biological desulfurization integrated system and method for hydrogen sulfide-containing gas

A biological desulfurization and biological technology, applied in the field of environmental engineering, can solve the problems of complex control, large area and many equipment, and achieve the effect of reducing the difficulty of control, reducing the area and convenient processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

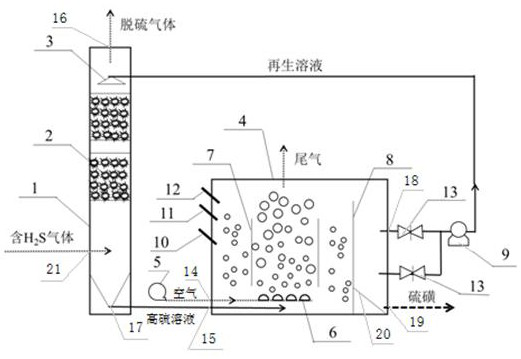

[0041] A biological desulfurization system, comprising an absorption tower 1 and a biological sulfur oxidation-sulfur separation integrated device 4, the bottom end of the absorption tower 1 is connected to the lower end of the biological sulfur oxidation-sulfur separation integrated device 4, and the middle end of the biological sulfur oxidation-sulfur separation integrated device 4 It is connected with the top of absorption tower 1.

[0042] The biosulfur oxidation-sulfur separation integrated device 4 includes a device body, in which a biosulfur oxidation zone and a sulfur separation zone are arranged sequentially from left to right, and a first air inlet 14 and a feed inlet are arranged on the left side of the device body 15. The first air inlet 14 is set above the feed port 15, and a diversion cylinder 7 is provided inside the biosulfur oxidation zone. There are intervals between the upper and lower ends of the diversion cylinder 7 and the device body. The diversion cylind...

Embodiment 2

[0050] Using the integrated biological desulfurization system for hydrogen sulfide-containing gas in Example 1, the height of the isolation plate 8 in this example is 2 / 3 of the height of the device body.

[0051] A biological desulfurization method for simulated gas containing hydrogen sulfide:

[0052] (1) The hydrogen sulfide content in the simulated gas is 10000ppm, and the rest is nitrogen, which is passed into the absorption tower 1 at a flow rate of 500L / h. The hydrogen sulfide in the gas is absorbed by the lye, and the purified gas is discharged from the top of the absorption tower 1; the absorption liquid The buffer solution configured for sodium carbonate-sodium bicarbonate has a pH of 9.0 and a sodium ion concentration of 1.0mol / L;

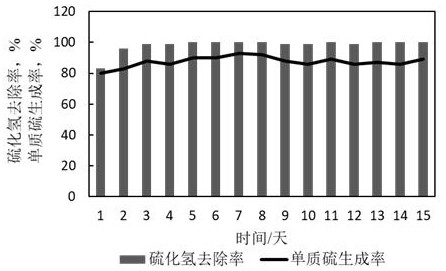

[0053] (2) The high-sulfur solution after absorbing hydrogen sulfide flows into the biosulfur oxidation zone in the biosulfur oxidation-sulfur separation integrated device 4 to carry out sulfur oxidation reaction. Under the condition of...

Embodiment 3

[0058] Using the integrated system for biological desulfurization of hydrogen sulfide-containing gas in Example 1, the height of the isolation plate 8 is 1 / 2 of the height of the device body.

[0059] A biological desulfurization method for natural gas containing hydrogen sulfide:

[0060] (1) The content of methane in natural gas is 90%, that of ethane is 5.5%, and that of hydrogen sulfide is 10,000ppm. The flow rate of 600L / h is passed into the absorption tower 1. The hydrogen sulfide in the gas is absorbed by the lye, and the purified gas is absorbed from the absorption tower. The top of the tower 1 is discharged; the absorption liquid is a buffer solution configured by sodium carbonate-sodium bicarbonate, the pH is 9.3, and the concentration of sodium ions is 0.9mol / L;

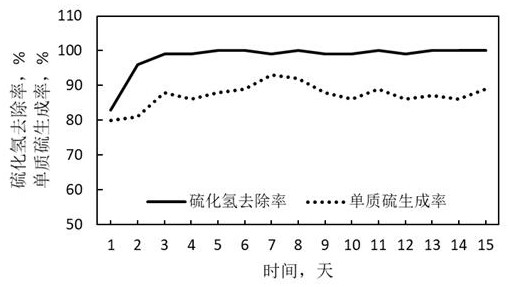

[0061] (2) The high-sulfur solution after absorbing hydrogen sulfide flows into the biosulfur oxidation zone in the biosulfur oxidation-sulfur separation integrated device 4 to carry out sulfur oxidation r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com