Separation and extraction method for sulfur powder in water during preparation of insoluble sulfur

A preparation process and technology of sulfur powder, applied in the field of non-metallic elements and their compounds, can solve the problems of no water, increase of separation equipment and difficulty, decrease of extraction efficiency, etc., achieve good high temperature stability, reduce fire and explosion occurrence The probability of separating simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

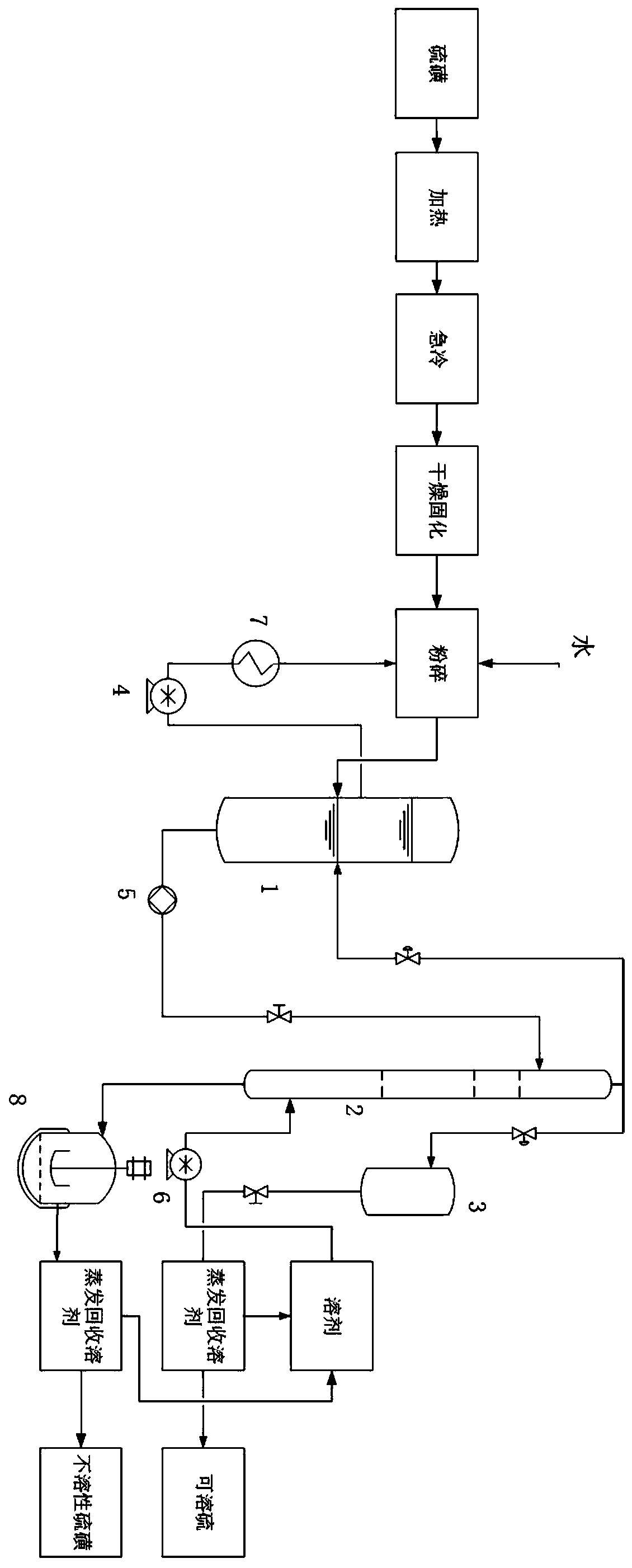

[0036] In the laboratory according to the characteristics of the present invention prepared a figure 1 A small-scale experimental device, the low-temperature melting method is used to obtain crude insoluble sulfur, wherein the content of insoluble sulfur is 35%, and the crude insoluble sulfur is a strip with a length of 5-10cm and a diameter of 1-2mm. The crude insoluble sulfur product is pulverized in water, and filtered with a filter to obtain the insoluble crude sulfur powder water slurry with a particle size of 100-400 mesh, and the insoluble crude sulfur powder slurry is pumped into the separation tank with a pump, and the separated water is reused, and then pumped to the separation tank. The solvent and sulfur powder slurry at the bottom of the separation tank are pumped into the upper inlet of the extraction tower, and the CS 2 into the lower inlet of the extraction tower, CS 2 No stabilizer was added to the mixture, the crude insoluble sulfur was mixed with CS 2 The ...

Embodiment 2

[0039] In the laboratory according to the characteristics of the present invention prepared a figure 1 A small-scale experimental device, using the gasification method to heat sulfur to 600 ° C, then quenching in aqueous solution, and then drying and solidifying to obtain crude insoluble sulfur, in which the content of insoluble sulfur is 62%, and the crude insoluble sulfur is 5-10cm in length Block shape, width 1-2cm, use a small pulverizer to pulverize the crude insoluble sulfur in water, control the pulverization temperature not higher than 80°C, and filter with a filter to obtain a slurry of crude insoluble sulfur powder with a particle size of 100-400 mesh, and use a pump Squeeze the insoluble crude sulfur powder water slurry into the separation tank, reuse the separated water, then pump the solvent and sulfur powder slurry at the bottom of the separation tank into the upper inlet of the extraction tower, and separate the CS 2 into the lower inlet of the extraction tower,...

Embodiment 3

[0041] In the laboratory according to the characteristics of the present invention prepared a figure 1 A small-scale experimental device, using the gasification method by heating sulfur to 600 ° C, and then in the CS 2 Medium rapid cooling, and then dried and solidified to obtain crude insoluble sulfur, in which the insoluble sulfur content is 41%. The crude insoluble sulfur is in the form of lumps. Use a small water phase pulverizer to pulverize the crude insoluble sulfur in water, and control the pulverization temperature is not high at 80°C, and filter with a filter to obtain the insoluble crude sulfur powder slurry with a particle size of 100-400 mesh, pump the insoluble crude sulfur powder slurry into the separation tank, reuse the separated water, and then pump the bottom of the separation tank The solvent and sulfur powder slurry are injected into the upper inlet of the extraction tower, and the CS 2 into the lower inlet of the extraction tower, CS 2 Add stabilizer, i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com