Wet forming equipment for sulphur and forming technology thereof

A technology of wet molding and sulfur, which is applied in the direction of sulfur preparation/purification, etc., can solve the problems of high maintenance cost, small output of a single machine, and high requirements for workers' operation level, and achieve high controllability, favorable dehydration, and high adjustability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

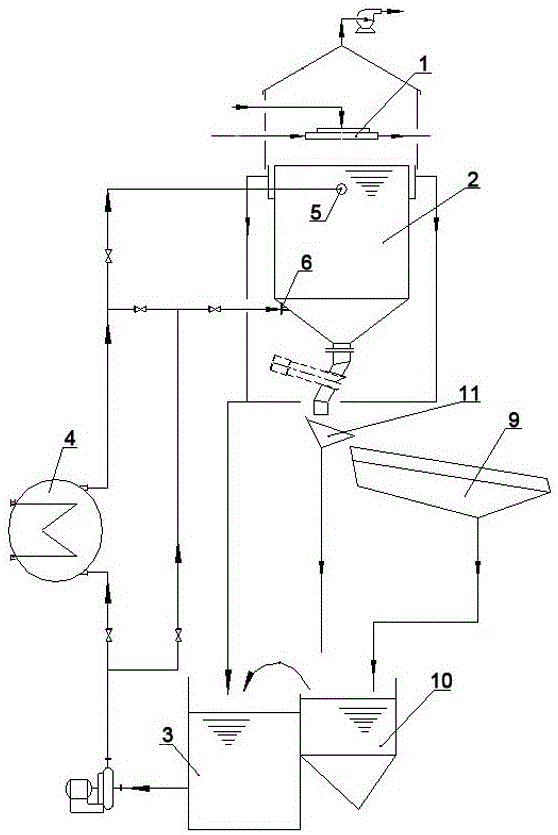

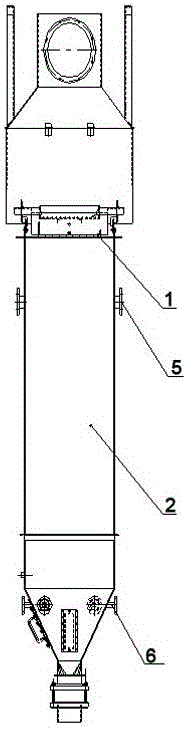

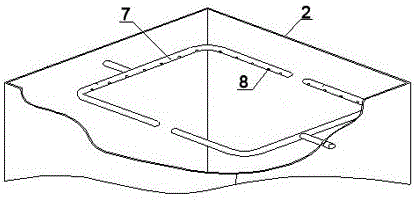

[0025] like figure 1 Shown: a kind of sulfur wet forming equipment, including forming plate 1, forming tank 2, hot water tank 3 and heat exchanger 4, forming plate 1 is set above forming tank 2, hot water tank 3 is set downstream of forming tank 2, A vibrating dewatering screen 9 and a settling tank 10 are arranged successively between the forming tank 2 and the hot water tank 3, the feeding port of the forming tank 2 is connected to the vibrating dewatering screen 9, the water outlet of the settling tank 10 is connected to the hot water tank 3, and the forming tank 2 and the vibrating dewatering screen 9 are also provided with a static curved screen 11, and the structure of the static curved screen 11 is as follows: Figure 8 As shown, the stationary curved screen 11 includes a casing and a semi-curved sieve plate 12 arranged in the casing. The upper end and the side wall of the casing are respectively provided with a feed port 13 and a discharge port 14, and the bottom of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com