Method for improving dewaterability of activated sludge through addition of microbial flocculant

A microbial flocculant and activated sludge technology, which is applied in the direction of dehydration/drying/thickened sludge treatment, can solve the problems of poor dehydration performance and high cost of mud cake subsequent treatment and disposal, and achieves easy operation, low investment and operation cost, and source wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

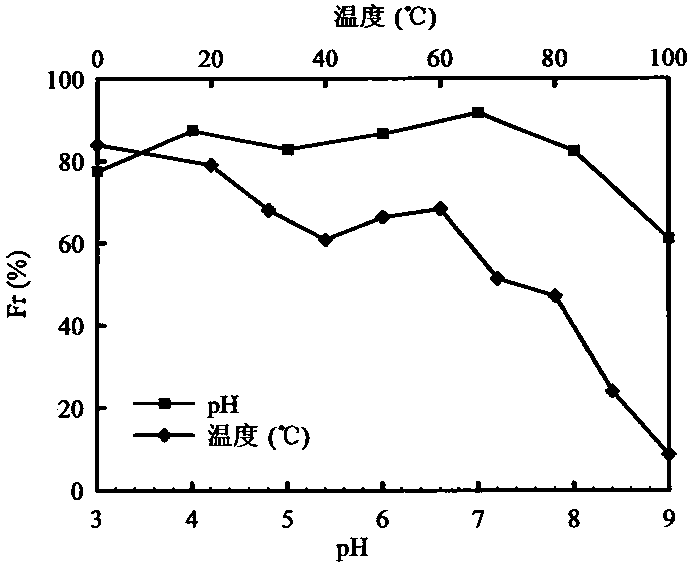

[0044] The fermented liquid after shaking culture was centrifuged at 5000r / min for 30min, and the supernatant was the liquid microbial flocculant, and the flocculant produced by Klebsiella isolated and screened was used to treat the 4g / L kaolin suspension solution. 0.4g of kaolin, 5mL of CaCl passed through a 60 mesh sieve 2 (1%) solution and 2mL fermentation supernatant were mixed in a 250mL beaker, added deionized water to 100mL, magnetic stirrer 400r / min fast stirring 1min, 150r / min slow stirring 5min, transferred to a 100mL graduated cylinder and left standing for 5min. Measure the absorbance (A) of the supernatant under the 550nm wavelength of the ultraviolet spectrophotometer, choose fresh medium to replace the fermentation broth, and measure the absorbance of the kaolin suspension after processing as a contrast (A 0 ) The calculation formula of flocculation rate (Fr) is as follows:

[0045] Fr = A ...

Embodiment 2

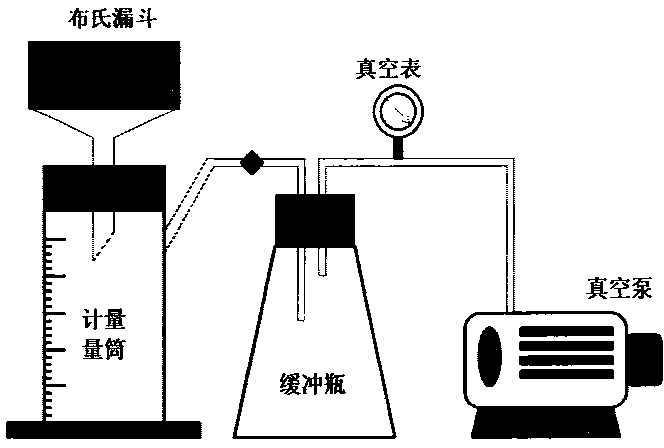

[0049] Application of Klebsiella flocculants to conditioned sludge to improve sludge dewaterability. 25mL of the sludge sample to be tested was added with 0-5mL of microbial flocculant, stirred rapidly at 400r / min for 60s on a magnetic stirrer, and slowly stirred at 150r / min for 5min, and moved to the sludge specific resistance measuring device (attached image 3 ), filter under the condition of constant vacuum 0.05MPa, record the filtration time t and the corresponding filtrate volume V. Sludge specific resistivity (SRF) and water content were selected to characterize the sludge dewatering effect, and the water content was determined by gravimetric method. Sludge specific resistance (Specific resistance in filtration, SRF) refers to the resistance of unit mass sludge on unit filtration area when filtering under constant pressure. The larger the sludge specific resistance, the worse the filtration performance. The calculation of sludge specific resistance is shown in the formu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com