High-concentration anaerobic sludge digestion treatment process for carrying out mechanical dewatering on sludge

An anaerobic digestion and pre-dehydration technology, applied in water/sludge/sewage treatment, sludge treatment, biological sludge treatment, etc. Huge, high infrastructure investment and operating costs, etc., to achieve the effect of reducing infrastructure investment and operating costs, low cost, and reduced transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is further illustrated by the following examples.

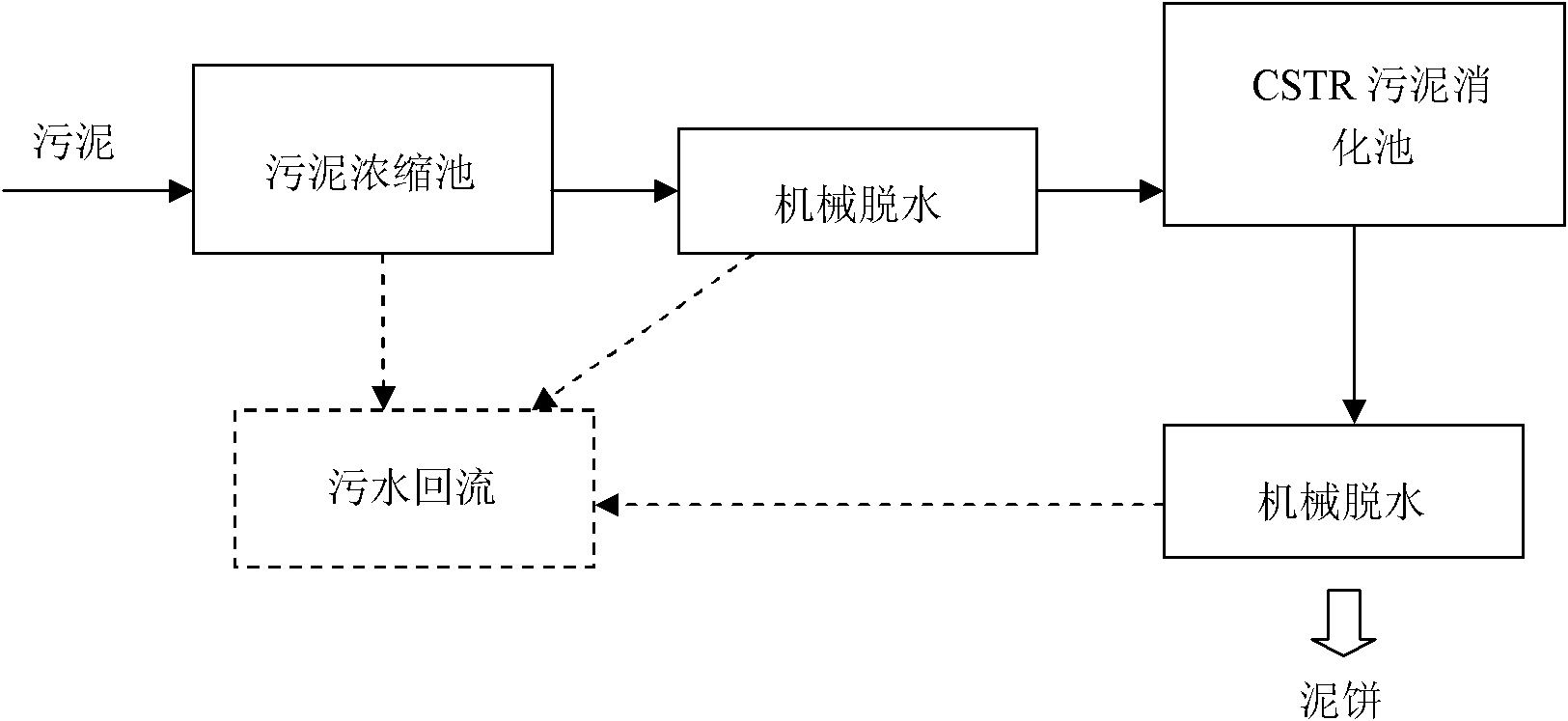

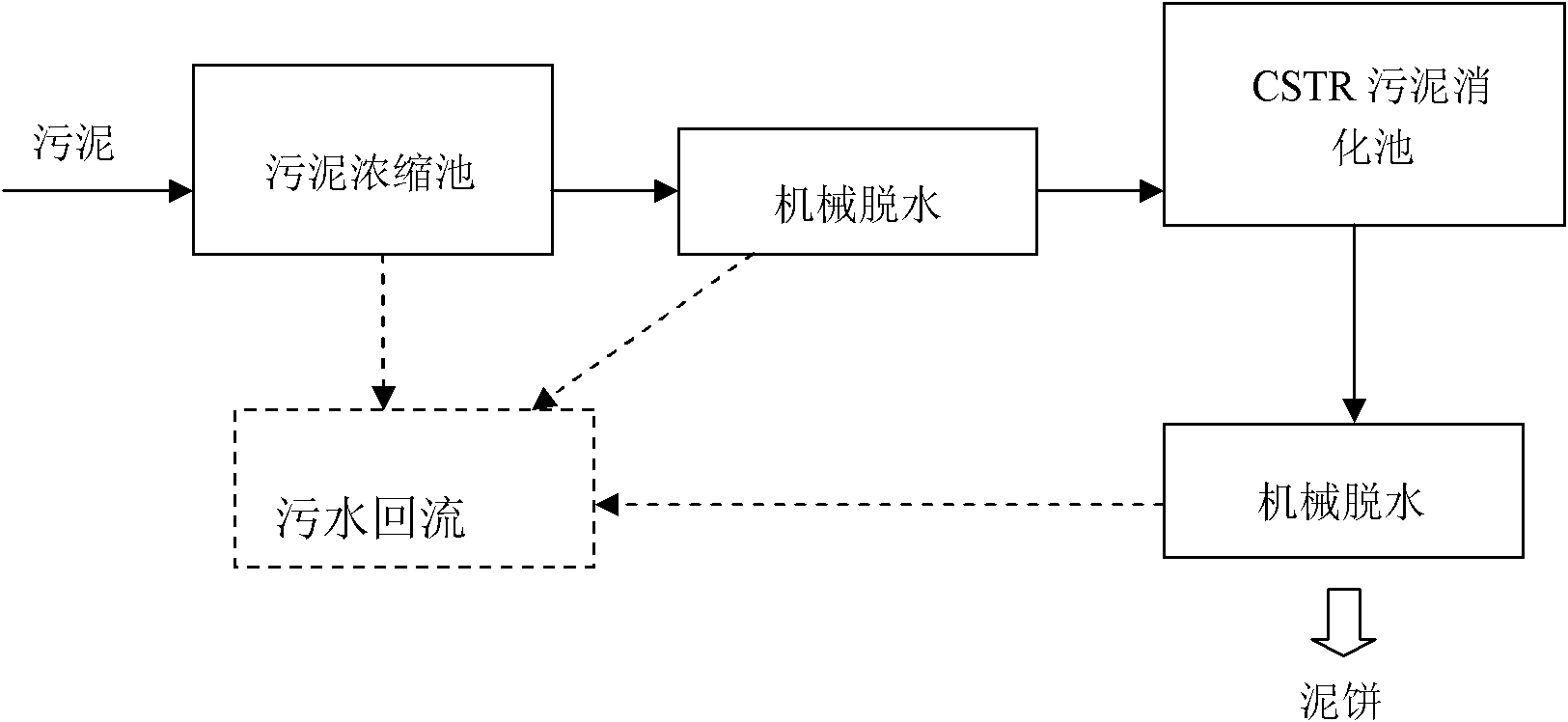

[0020] Sludge Concentration: The remaining sludge (water content above 99%) of the sewage treatment plant is sent to the gravity concentration tank by sludge pump. The water content of the concentrated sludge is generally 97%. When the water content drops from 99% to At 97%, the volume of the sludge can be reduced to 1 / 3 of the original. The separated supernatant is returned to the sewage treatment system.

[0021] Sludge pre-dehydration: After thickening, the sludge enters the dehydration machine room and is dehydrated by the sludge mechanical dehydration equipment. The moisture content of the sludge is controlled at about 88% to 90%.

[0022] Anaerobic sludge digestion: The dehydrated sludge is pumped into the CSTR anaerobic sludge digester by the sludge pump. The moisture content of the sludge after pre-dehydration is low, about 88% to 90%. Compared with the traditional process, it can greatl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com