Preparation method of composite anode material for lithium element sulphur secondary battery

A composite cathode material, sulfur secondary battery technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problem of unsolved conductivity of elemental sulfur electrodes, and achieve good application prospects, simple preparation methods, and uniform distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

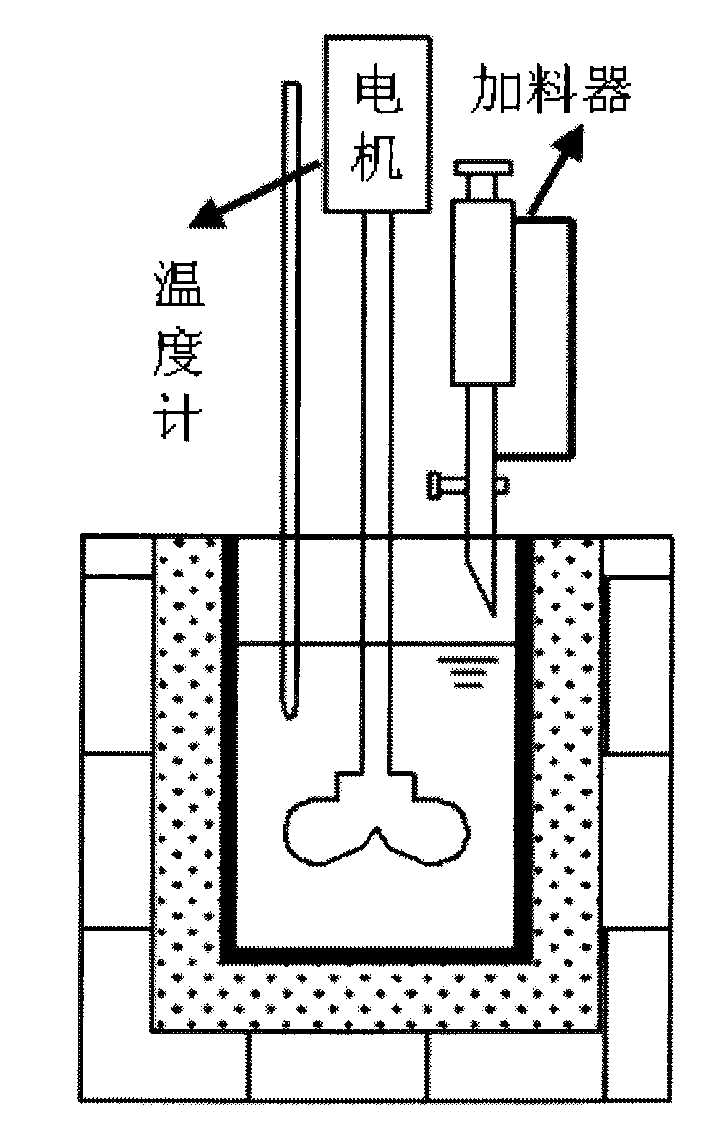

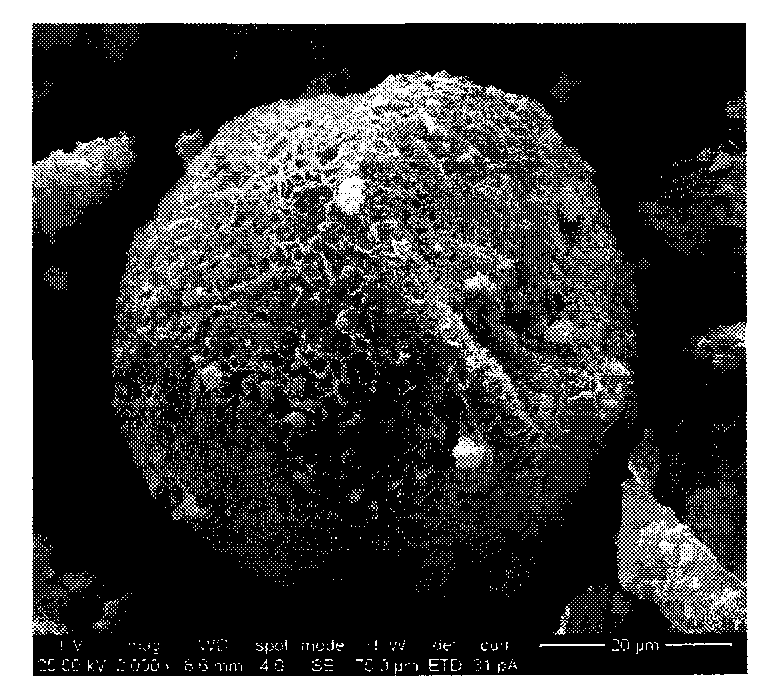

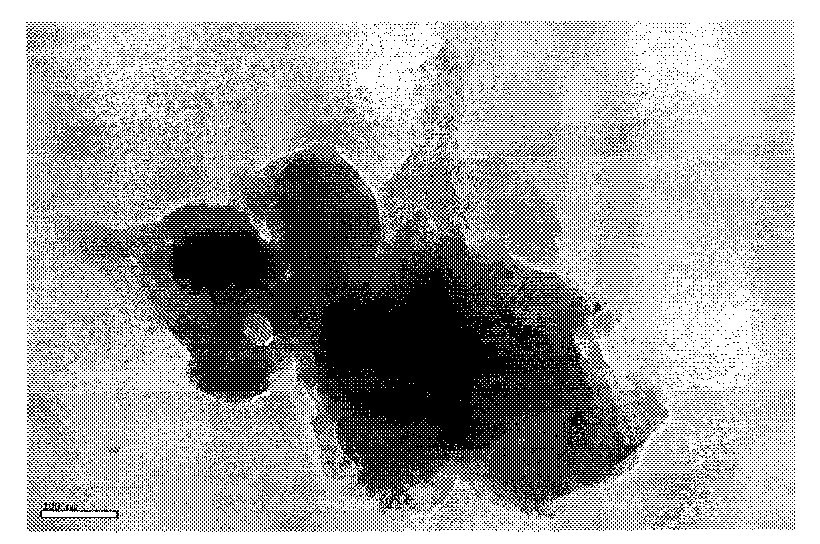

[0030] Weigh elemental sulfur (100 mesh, Aldrich) and thiophene monomer (analytical pure, Sinopharm Group) with a mass ratio of 30:70, and weigh anhydrous ferric chloride (chemically pure, Sinopharm Group) with a molar ratio of 1:4 . Put elemental sulfur and anhydrous ferric chloride into the reaction kettle, and add anhydrous chloroform until the solids are completely submerged. Control the temperature in the kettle at 0-10°C, and stir at a speed of 1000r / min for 30 minutes to mix the solids evenly. Put the quantitative monomer thiophene into the feeder and slowly and evenly add it to the reaction kettle. Keep stirring at a speed of 1000r / min and keep the temperature in the kettle at 0-10°C for 10 hours throughout the whole process, so that the thiophene monomer and the anhydrous ferric chloride adsorbed on the surface of the elemental sulfur undergo in-situ chemical polymerization. Then the excess waste liquid was filtered off, and anhydrous methanol was added to wash for ...

Embodiment 2

[0034]Weigh elemental sulfur and thiophene monomer with a mass ratio of 40:60, and weigh anhydrous ferric chloride with a molar ratio of 1:4. Put elemental sulfur and anhydrous ferric chloride into the reaction kettle, and add anhydrous chloroform until the solids are completely submerged. Control the temperature in the kettle at 0-10°C, and stir at a speed of 1000r / min for 30 minutes to mix the solids evenly. Put the quantitative monomer thiophene into the feeder and slowly and evenly add it to the reaction kettle. Keep stirring at a speed of 1000r / min and keep the temperature in the kettle at 0-10°C for 10 hours throughout the whole process, so that the thiophene monomer and the anhydrous ferric chloride adsorbed on the surface of the elemental sulfur undergo in-situ chemical polymerization. Then the excess waste liquid was filtered off, and anhydrous methanol was added to wash for several times until the filtrate was colorless. Then add deionized water to wash until the f...

Embodiment 3

[0038] Weigh elemental sulfur and thiophene monomer with a mass ratio of 55:45, and weigh anhydrous ferric chloride with a molar ratio of 1:4. Put elemental sulfur and anhydrous ferric chloride into the reaction kettle, and add anhydrous chloroform until the solids are completely submerged. Control the temperature in the kettle at 0-10°C, and stir at a speed of 1000r / min for 30 minutes to mix the solids evenly. Put the quantitative monomer thiophene into the feeder and slowly and evenly add it to the reaction kettle. Keep stirring at a speed of 1000r / min throughout the whole process and keep the temperature in the kettle at 0-10°C for 10 hours to make in-situ chemical polymerization of thiophene monomer and anhydrous ferric chloride adsorbed on the surface of elemental sulfur. Then the excess waste liquid was filtered off, and anhydrous methanol was added to wash for several times until the filtrate was colorless. Then add deionized water to wash until the filtrate is neutra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com