Sulphur granulation apparatus and process

A technology of granules and granular granules, applied in the field of sulfur particles, which can solve the problems of large footprint, insufficient quality control, expensive manufacturing and operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

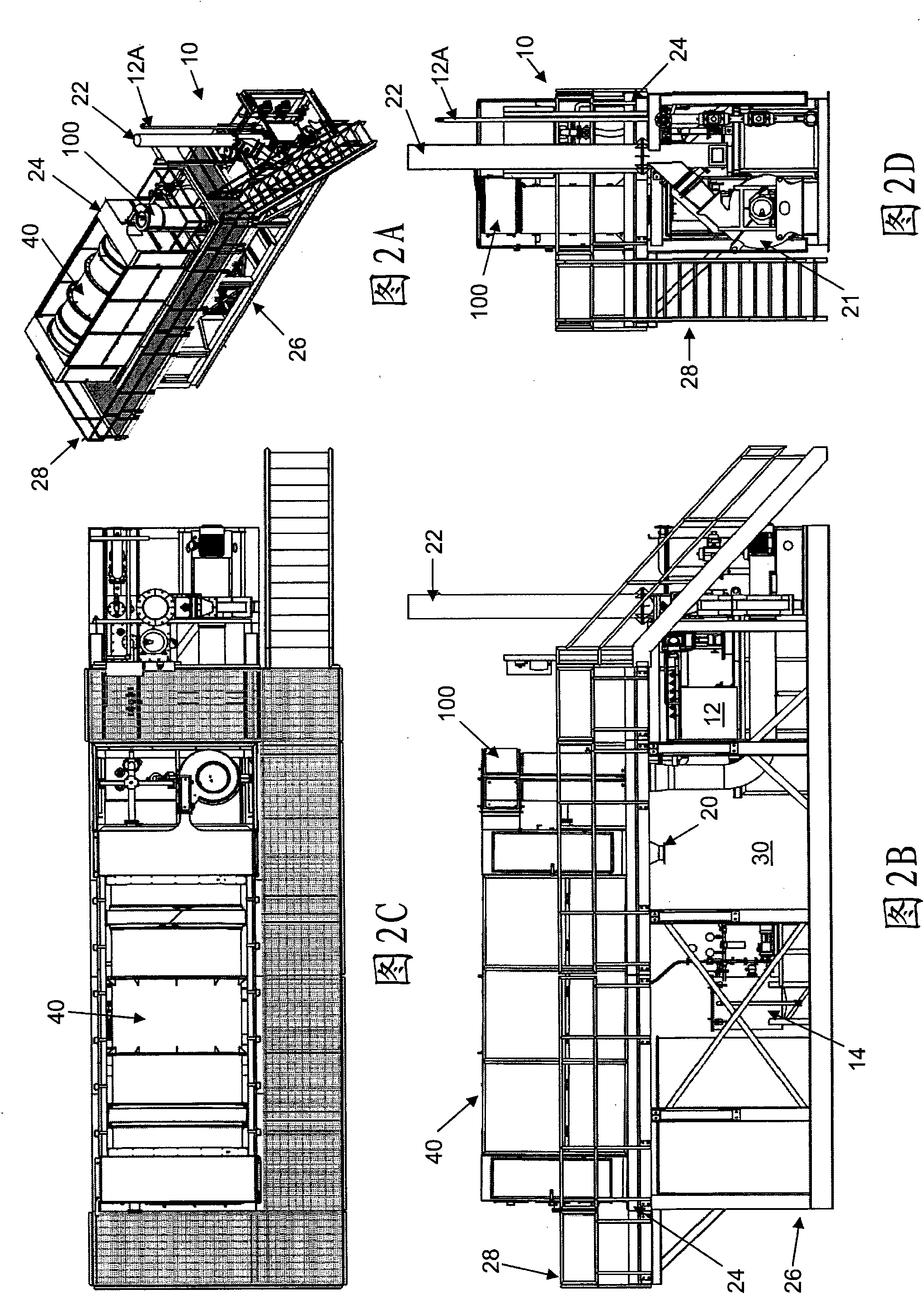

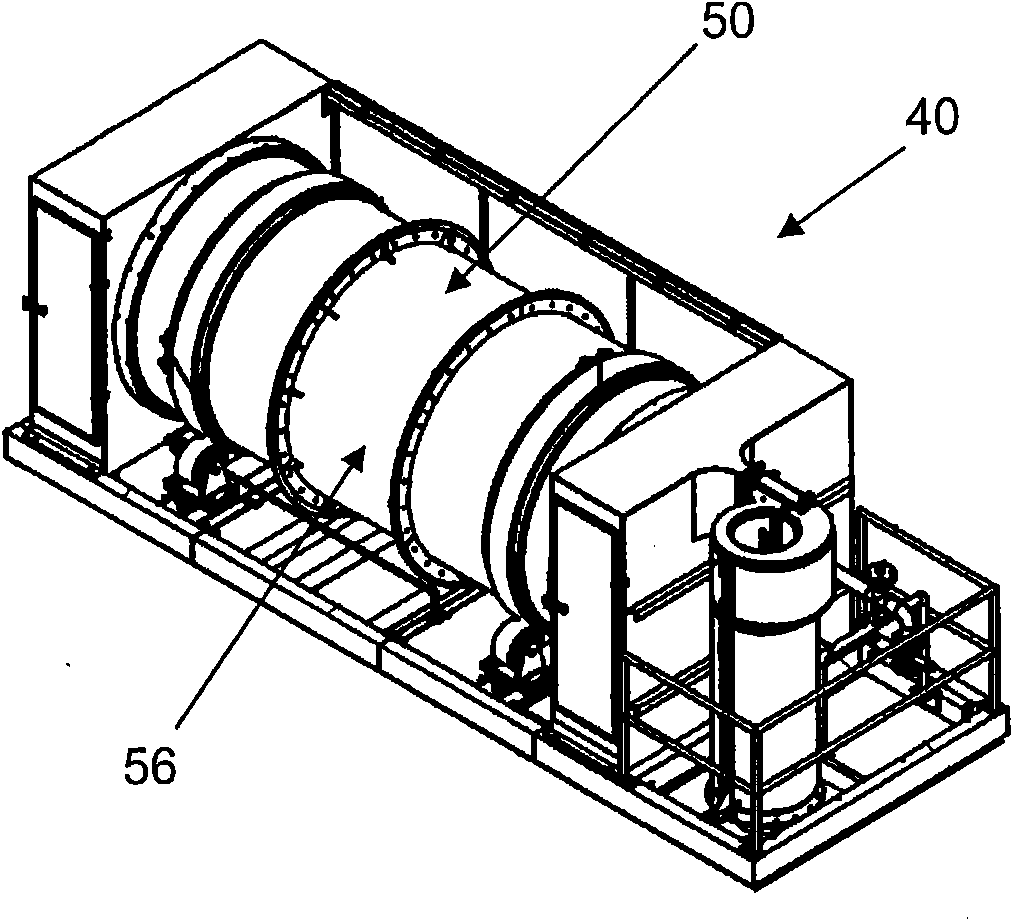

[0050] The present invention is an apparatus, indicated generally in the drawings by reference numeral 10, and a method for producing granular particles from a processing fluid in a single pass through the apparatus. The particles may also be referred to herein as granular solids, particulates or "products" and the processing fluids may encompass the known range of suitable liquefied substances such as urea and bentonite fertilizers. For descriptive purposes, the preferred processing fluid is molten sulfur for the formation of sulfur particulates. It should also be noted that terms such as "front", "rear", "upper", "lower" etc. may also be used to identify certain parts of the device. The use of these terms is not necessarily intended to limit their application or location. In addition, when describing the present invention, all terms not defined herein have their commonly known meanings in the art.

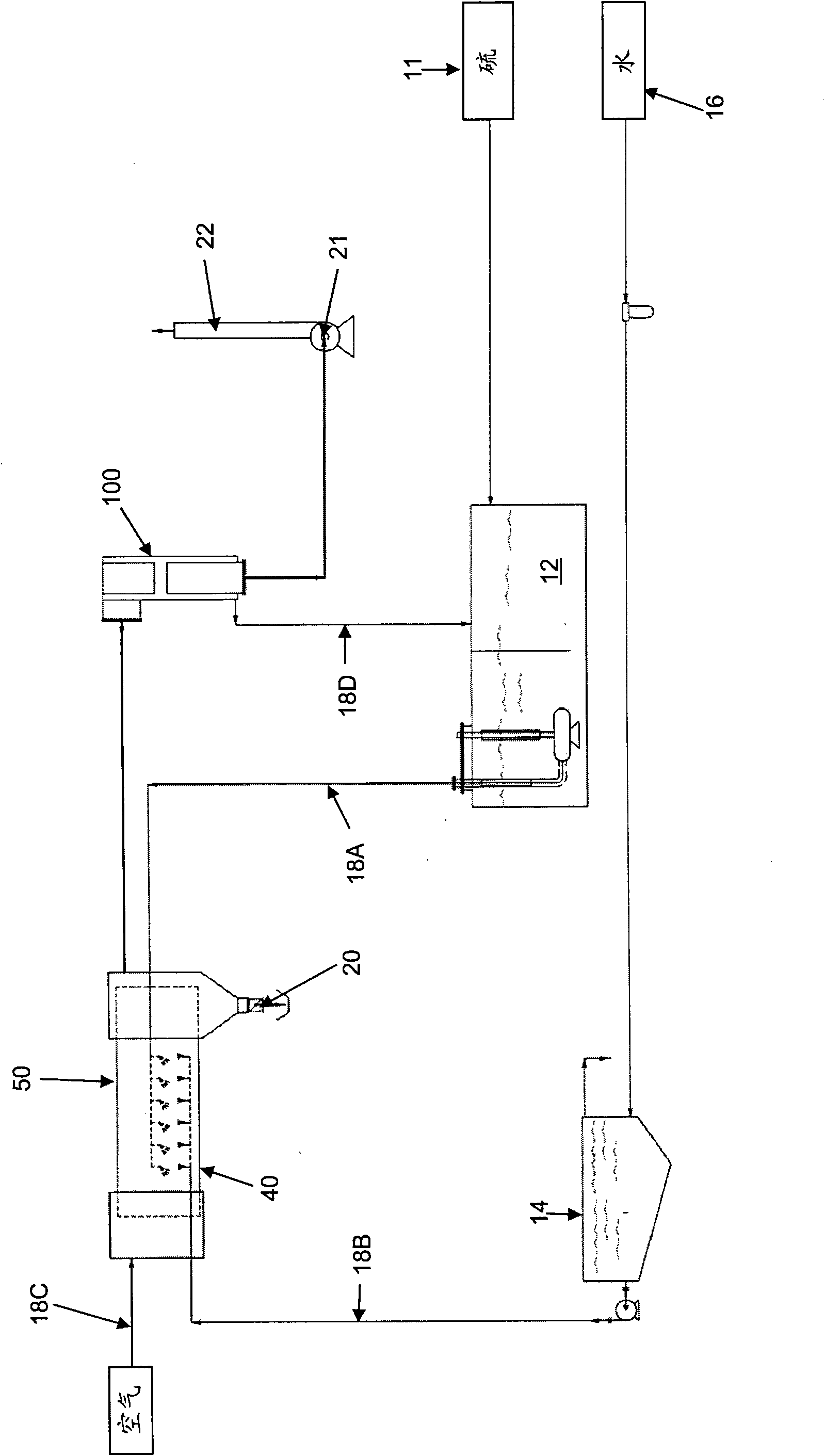

[0051] First refer to figure 1 , the present pelletizing process includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com