Method and device for preparing sulfur by recovering hydrogen sulfide gas from viscose waste gas

A gas recovery and hydrogen sulfide technology, applied in chemical instruments and methods, sulfur compounds, sulfur preparation/purification, etc., can solve the problems of large sulfur-containing wastewater and miscellaneous salts, inability to maintain temperature, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

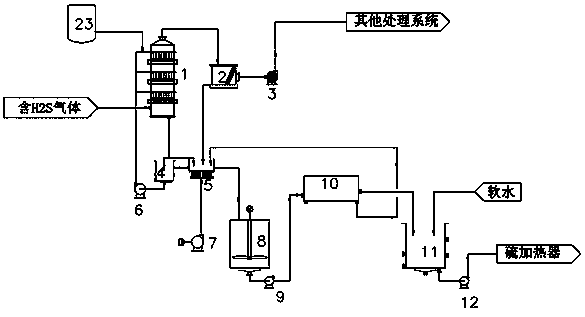

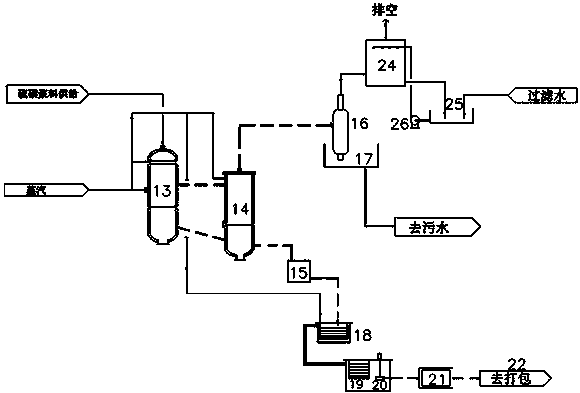

[0049] figure 1 including scrubber 1 (H 2 S washing tower), demister 2, demister fan 3, washing liquid circulation tank 4, demister 5, washing liquid circulation pump 6, blower 7, foam collection tank 8, foam delivery pump 9, centrifuge 10, sulfur Slurry collection tank 11, sulfur slurry delivery pump 12, sulfur heater 13, molten sulfur separator 14, molten sulfur collection tank 15, gas-liquid separator 16, waste liquid collection tank 17, molten sulfur standing tank 18, molten sulfur transfer Tank 19, submerged pump 20, granulator 21, baler 22, washing liquid preparation tank 23, flash cooler 24, water washing circulation tank 25, water washing pump 26. The viscose waste gas pipeline (containing hydrogen sulfide waste gas) is connected to the air inlet at the lower part of the scrubber 1, and the gas outlet at the top of the scrubber 1 is connected to the air inlet of the demister 2. The washing tower 1 has three liquid inlets in the upper, middle and lower parts. The wash...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com