Composite desulfurizing agent

A technology of desulfurization agent and settling agent, which is applied to the separation of dispersed particles, chemical instruments and methods, and separation methods. It can solve the problems of desulfurization performance of desulfurization liquid, high cost of liquid treatment, and restrictions on wide use, etc., and achieve less auxiliary salt. , to avoid desulfurization performance decline, the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

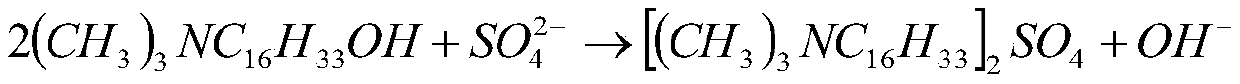

Method used

Image

Examples

Embodiment 1

[0027] (1) In terms of mass percentage, the desulfurizer uses water as a solvent, and its composition is as follows:

[0028] Sodium iron edetate, 110g / L;

[0029] Sodium carbonate, 8g / L;

[0030] Polyacrylamide 1.1g / L;

[0031] Sodium polyacrylate, 450mg / L;

[0032] Polyaluminum chloride, 20mg / L;

[0033] Cetyltrimethylammonium hydroxide, 30mg / L;

[0034] Borax, 1.2g / L

[0035] Hydroquinone, 250mg / L,

[0036] the rest is water

[0037] Its configuration method: use water as a solvent, add sodium ferric edetate, stir for 1 hour to fully dissolve, then add borax, sodium carbonate, polyacrylamide, sodium polyacrylate, polyaluminum chloride and hydroquinone and stir , to make it evenly mixed, and the pH value of the finally obtained desulfurization liquid is 8.2.

[0038] (2) test

[0039] A: Sulfur-containing gas (coke oven gas) absorption conditions:

[0040] Gas flow (Nm 3 / h): 35000

[0041] Hydrogen sulfide content (v / v%): 0.527~0.857

[0042] Gas temperature (℃...

Embodiment 2

[0049] (1) In terms of mass percentage, the desulfurizer uses water as a solvent, and its composition is as follows:

[0050] Sodium iron edetate, 70g / L;

[0051] Sodium carbonate, 5g / L;

[0052] Polyacrylamide 1g / L;

[0053] Sodium polyacrylate, 450mg / L;

[0054] Polyaluminum chloride, 25mg / L;

[0055] Cetyltrimethylammonium hydroxide, 50mg / L;

[0056] Borax, 1.2g / L

[0057] Hydroquinone, 300mg / L,

[0058] the rest is water

[0059] Its configuration method: use water as a solvent, add sodium ferric edetate, stir for 1 hour to fully dissolve, then add borax, sodium carbonate, polyacrylamide, sodium polyacrylate, polyaluminum chloride and hydroquinone and stir , to make it evenly mixed, and the pH value of the finally obtained desulfurization liquid is 7.5.

[0060] (3) test

[0061] Sulfur-containing gas (natural gas field water flash steam) absorption conditions:

[0062] Gas flow (Nm 3 / d): 200~300

[0063] Hydrogen sulfide content (g / Nm 3 ): 100~150

[0064] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com