Preparation method for multistage separation extraction of earthworm active proteins and method

A technology for active protein and multi-stage separation, which is applied in the field of multi-stage separation and extraction of earthworm active protein preparation devices, can solve the problems of large liquid holding capacity at the outlet of a foam tower, difficult protein enrichment ratio, and difficulty in draining the foam layer, and achieves improved performance. The effect of enrichment ratio and increasing recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

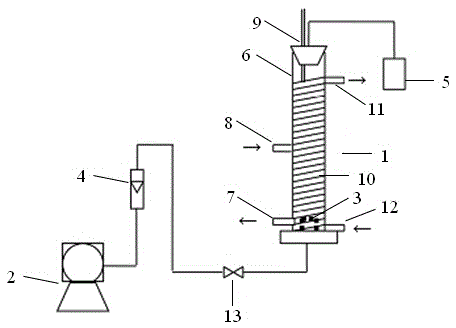

[0020] A preparation method for multistage separation and extraction of earthworm active protein, comprising the following steps:

[0021] The collection detection of 1 earthworm protein homogenate feed liquid: collect earthworm protein homogenate feed liquid volume and be 2500ml, detect protein concentration and should be 30.79g / L and pH value 3.9;

[0022] II earthworm protein homogenate feed liquid pretreatment: use the pH value adjustment solution to adjust the pH value of the earthworm protein homogenate feed liquid described in the first step to 3.9, as the feed of the first stage foam separation process in step III;

[0023] III First-stage foam separation: Operate under the conditions of superficial gas velocity of 40-60ml / min and temperature of 50-60°C to break the foam layer until the foam no longer overflows from the top of the constant temperature foam separation column 1 Stop aeration, collect foam and carry out defoaming in foam collecting device 5, defoaming liq...

specific Embodiment 1

[0029] Preparation materials used in this specific example: Daping No. 2 earthworm, Baiming Technology Co., Ltd.; Coomassie Brilliant Blue G250 biological reagent.

[0030] The specific model of the preparation equipment used: rotameter 3WB, Changzhou Shuanghuan; foaming tower with sieve plate 610mm×80mm, customized by Beijing Xinwell; air pump FB-280, Shanghai Jaguar; spectrophotometer L6S, Shanghai Jingke; constant temperature water bath HH-3, Jiangsu Ronghua.

[0031] making process:

[0032] Wash 100g of fresh earthworms with water, add 250ml of distilled water to make a coarse homogenate, centrifuge at 4000r / min for 20min, and collect the supernatant; add 250ml of distilled water to the sediment to continue homogenization, centrifuge at 4000r / min for 20min, collect the supernatant; repeat extraction Until the supernatant is clarified (10 times in total). Combine the supernatants from the previous several times, adjust the pH value to 3.9, and raise the temperature to 55...

specific Embodiment 2

[0036] Preparation materials used in this specific example: Daping No. 2 earthworm, Baiming Technology Co., Ltd.; Coomassie Brilliant Blue G250 biological reagent.

[0037]The specific model of the preparation equipment used: rotameter 3WB, Changzhou Shuanghuan; foaming tower with sieve plate 610mm×80mm, customized by Beijing Xinwell; air pump FB-280, Shanghai Jaguar; spectrophotometer L6S, Shanghai Jingke; constant temperature water bath HH-3, Jiangsu Ronghua.

[0038] making process:

[0039] Wash 100g of fresh earthworms with water, add 250ml of distilled water to make a coarse homogenate, centrifuge at 4000r / min for 20min, and collect the supernatant; add 250ml of distilled water to the sediment to continue homogenization, centrifuge at 4000r / min for 20min, collect the supernatant; repeat extraction Until the supernatant is clarified (10 times in total). Combine the previous supernatants, adjust the pH value to 3.9, and raise the temperature to 50°C with a water bath. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com