Preparation method of tara industrial tannic acid

A technology of tannic acid and tara, applied in the preparation of sugar derivatives, chemical instruments and methods, sugar derivatives, etc., can solve difficult problems such as separation and purification of active ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

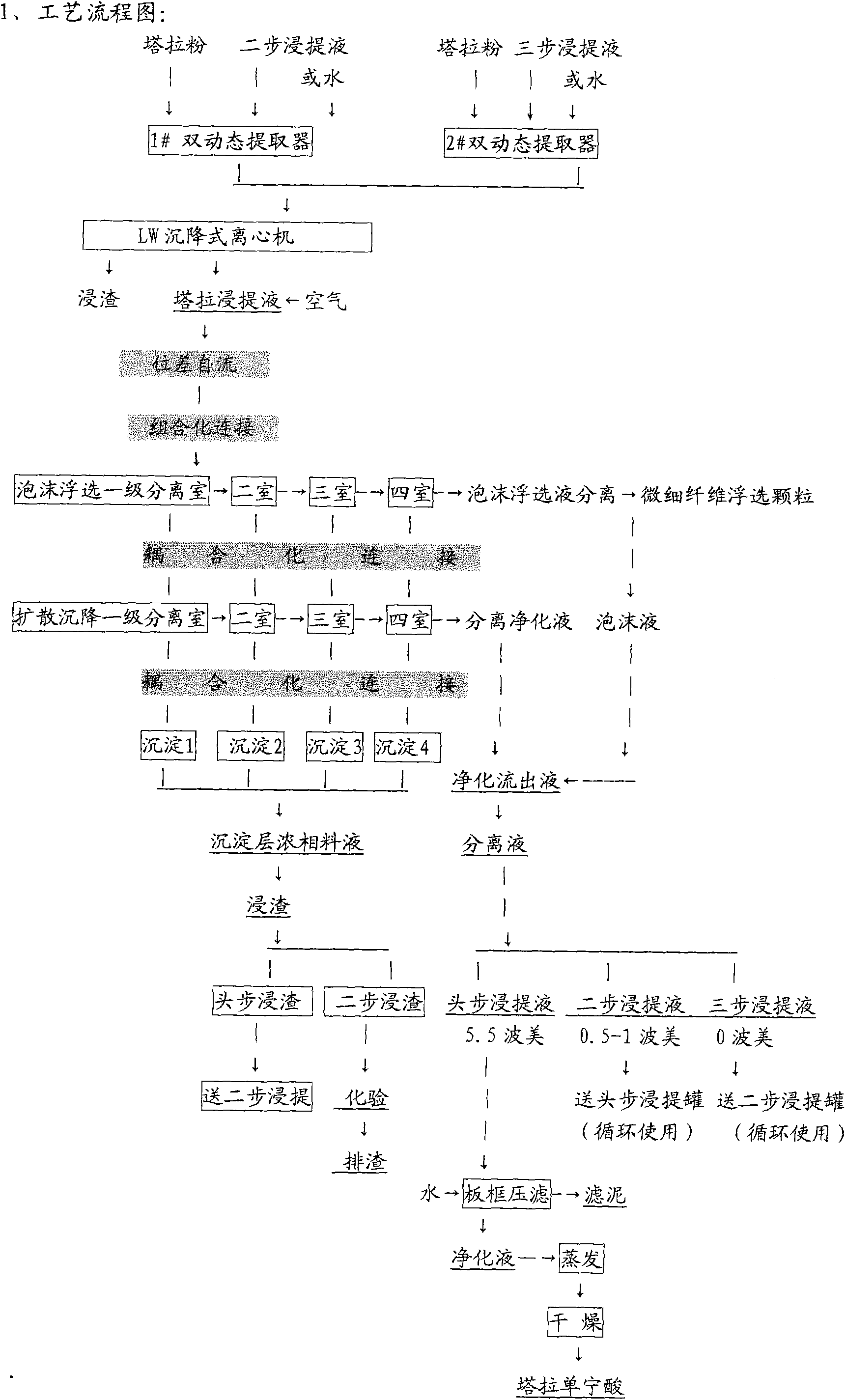

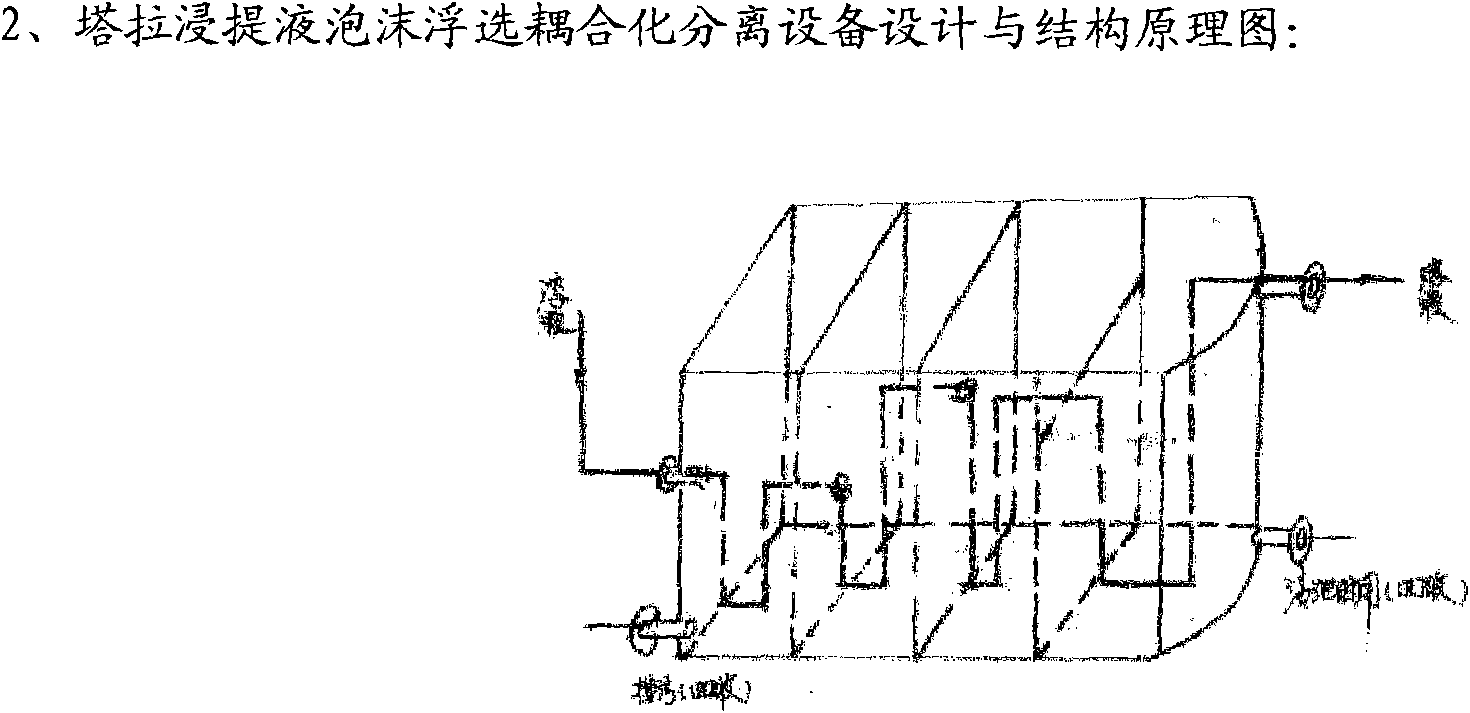

Method used

Image

Examples

Embodiment 1

[0056] A kind of preparation method of Tara technical grade tannic acid is characterized in that comprising the following steps:

[0057] In the first step, the commercial tara powder uses a 400-type pulverizer, 3700RPN, and a sieve bottom of 80-100 mesh.

[0058] In the second step, the Tara powder extraction process adopts a low-temperature two-tank three-step dual-dynamic countercurrent extraction process.

[0059] One-step extraction temperature: 35-45°C, two-step extraction: 40-50°C, three-step extraction: 45-55°C.

[0060] One-step extraction time: 0.5~1hr, two-step extraction time: 0.5~1hr, three-step extraction extraction time: 0.5~1hr.

[0061] One-step extraction solid-liquid ratio: 1:5-6, two-step extraction solid-liquid ratio: 1:4-5, three-step extraction solid-liquid ratio: 1:3-4.

[0062] The third step is to add the Tara powder raw material and water into the double dynamic extractor at a solid-liquid ratio of 1:4-6 according to the above extraction process, h...

Embodiment 2

[0075] Weigh 500kg 80-100 mesh tara powder and place it in a 3000-liter glass-lined or stainless steel dynamic extraction tank with stirring and condenser. The extraction process of tara powder adopts a low-temperature two-tank three-step double dynamic countercurrent extraction process.

[0076] One-step extraction temperature: 40°C, two-step extraction: 45°C, three-step extraction: 50°C.

[0077] One-step extraction time: 0.5hr, two-step extraction time: 0.5hr, three-step extraction extraction time: 0.5hr.

[0078] One-step extraction solid-liquid ratio: 1:5, one-step extraction solid-liquid ratio: 1:4, one-step extraction solid-liquid ratio: 1:3.

[0079] According to the above-mentioned extraction process, the raw materials of Tara powder and water are added into a double dynamic extractor with a solid-liquid ratio of 1:3-5, heated, kept warm, and extracted to prepare a solid-liquid extraction mixture of Tara powder.

[0080] Tara powder solid-liquid extraction mixed liqu...

Embodiment 3

[0092] Weigh 520kg of 80-100 mesh tara powder and place it in a 3000 liter glass-lined or stainless steel dynamic extraction tank with stirring and condenser.

[0093] One-step extraction temperature: 38°C, two-step extraction: 42°C, three-step extraction: 45°C.

[0094] One-step extraction time: 0.5hr, two-step extraction time: 0.5hr, three-step extraction extraction time: 0.4hr.

[0095] One-step extraction solid-liquid ratio: 1:6, one-step extraction solid-liquid ratio: 1:5, one-step extraction solid-liquid ratio: 1:4.

[0096] According to the above leaching process, the raw materials of Tara powder and water are added into a double dynamic extractor with a solid-liquid ratio of 1:4-6, heated, kept warm, and extracted to prepare a solid-liquid extraction mixture of Tara powder.

[0097] Tara powder solid-liquid extraction mixed liquid separation adopts spiral sedimentation centrifugal separation (horizontal spiral discharge centrifugal separation) process, that is, LW hor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com