Advanced treatment process for gas field produced water

A gas field produced water, advanced treatment technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. Foam and other problems, to achieve the effect of small footprint, reduced foaming tendency, and reduced odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] The advanced treatment process of gas field produced water includes the following steps:

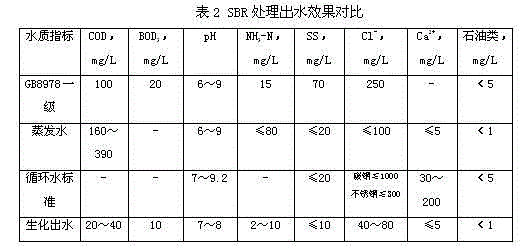

[0034] Foam separation process: The produced water is passed into the foam separator, and air is introduced into the water through the ejector and the aerator, so that the produced water and the micro-bubbles are fully mixed. The surface tension of the interface and electrostatic adsorption can separate the foaming substances, residues and suspended substances in the water from the adhesion in the water, so as to achieve the purpose of separating the foam substances and controlling the water quality, so as to obtain the clear liquid. Among them, the gas flow rate is 9 ~ 200m 3 / h, pressure 0.05MPa. The operating parameters of the above-mentioned foam separator are: flow rate 4m 3 / h, jet pump power: 0.55KW, gas-liquid ratio: (30-90):1. The indicators of the produced water after treatment by the foam separator are shown in Table 1:

[0035]

[0036] It can be seen from Table...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com