Thermal equipment for producing composite ceramic solar panel

A technology of ceramic plates and heat-resistant baffles is applied in lighting and heating equipment, ceramic material production, heating to dry solid materials, etc. , to achieve the effect of improving production efficiency and yield, reducing heat conduction distance and stabilizing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

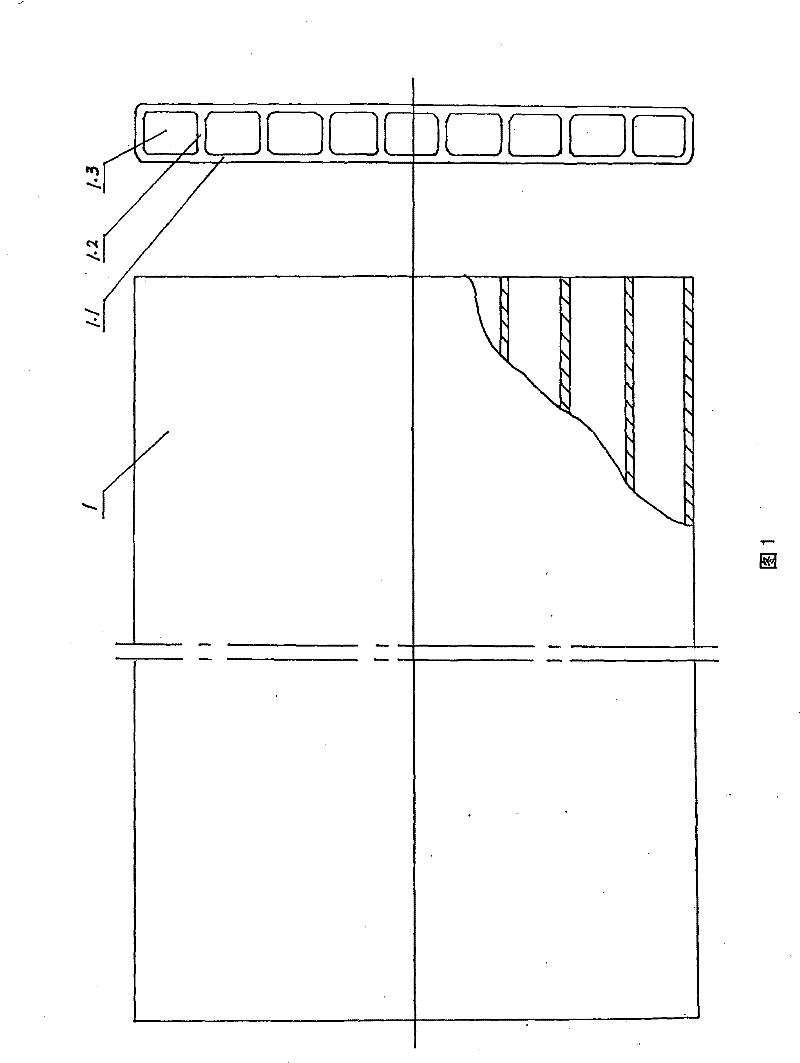

[0059] 1. The roller kiln is used for drying the hollow ceramic slab blanks with through-hole flat box structure. A movable baffle is installed in the hearth of the roller kiln. The position of the baffle can be adjusted to change the cross-sectional area of the furnace. The baffle is positioned by the boom and the cam. Lift the boom or turn the cam to raise and lower the flat baffle and change the angle of the inclined baffle. The movable baffle, boom and cam are made of stainless steel. Adjust the position of the baffle to make the hollow ceramic The inner and outer surfaces of the slab are dried simultaneously.

[0060] 2. The roller kiln used for firing the through-hole flat box structure hollow ceramic slab green body. A movable baffle is installed in the hearth of the roller kiln. The position of the baffle can be adjusted to change the cross-sectional area of the furnace. The movable baffle is positioned by the boom and the cam. Lift the boom or turn the cam to rais...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com