Heat radiation structure and electronic water pump

A technology of heat dissipation structure and electronic water pump, applied in the direction of pumps, pump components, pump devices, etc., can solve the problems of lack of auxiliary support structure, poor cooling effect, large magnetic leakage of permanent magnets, etc., to achieve good heat transfer effect and improve the motor. Efficiency, volume reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

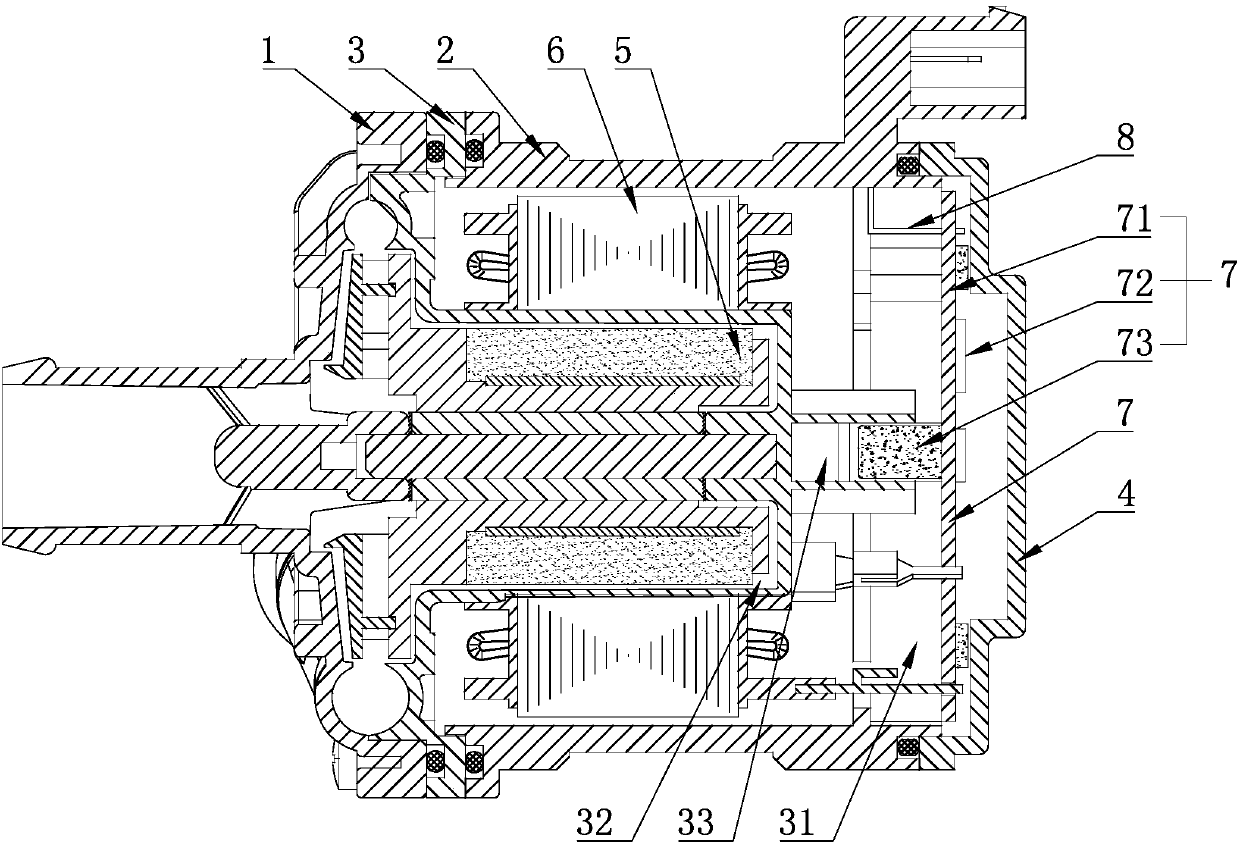

[0037] refer to Figure 1 to Figure 11 Embodiments of a heat dissipation structure and an electronic water pump of the present invention are further described.

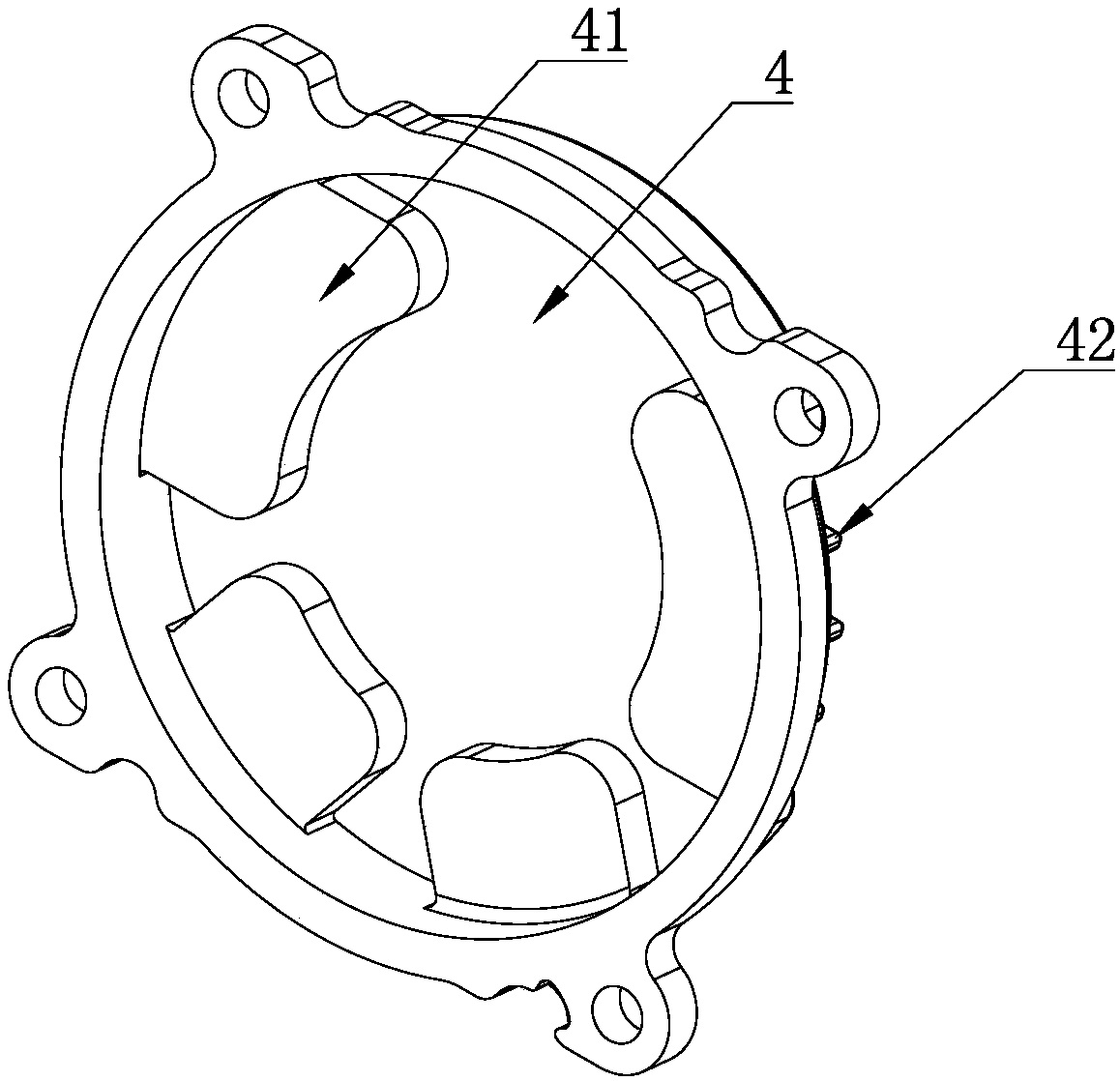

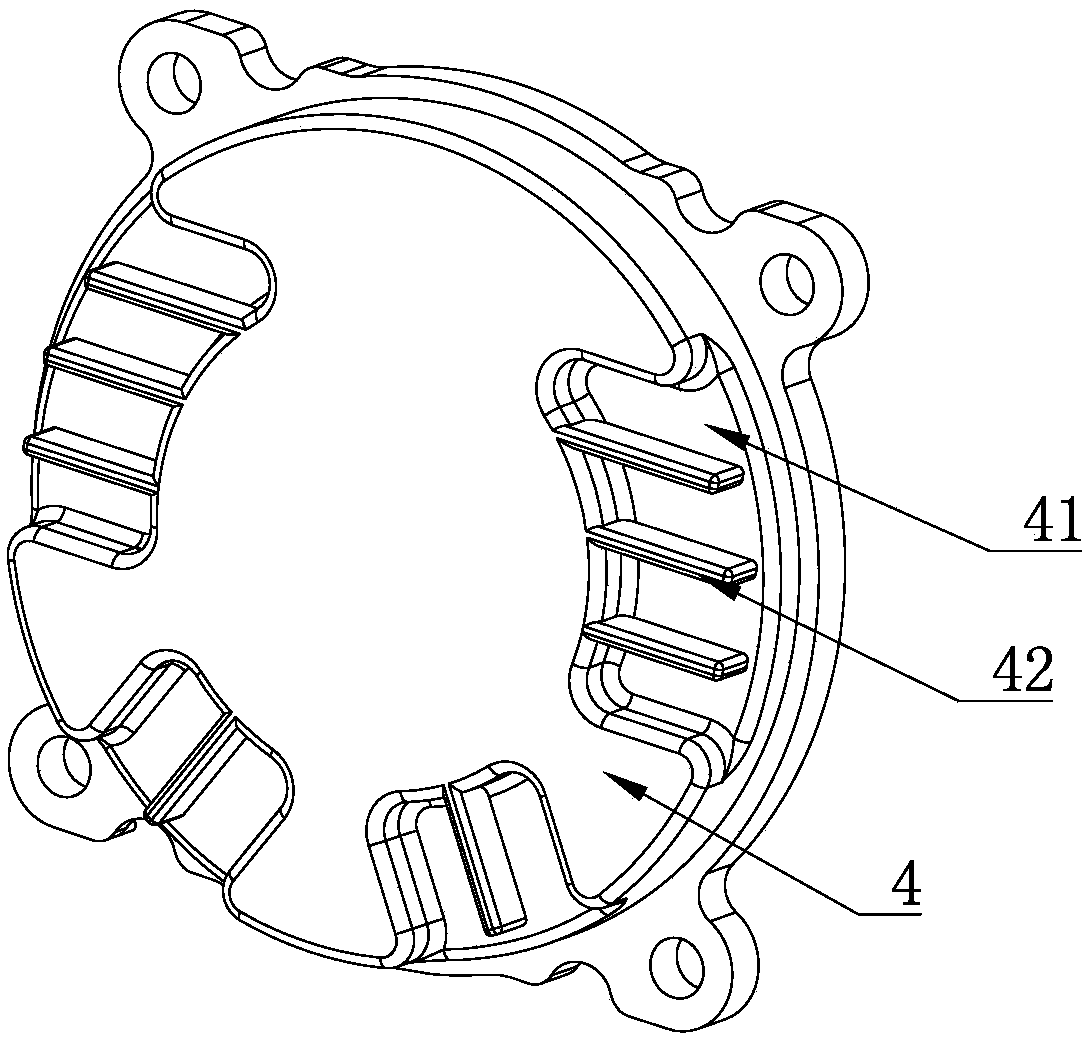

[0038] A heat dissipation structure such as Figure 2 to Figure 4 As shown, the metal heat dissipation cover 4 is included, and the metal heat dissipation cover 4 has good heat transfer effect. The heat dissipation cover 4 is provided with several heat conduction bosses 41 corresponding to the heating components. The direction of the heating element is raised and formed, and the side of the heat conducting boss 41 away from the heating element forms a heat dissipation groove. A plurality of heat sinks 42 integrally formed with the heat conducting boss 41 are arranged in the heat dissipation groove, facing the heat conducting boss of the heating element. 41 shortens the heat conduction distance and increases the heat conduction efficiency. The heat generated by the heating components is transferred to the heat conduct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com