Temperature measurement assembly and electric equipment

A technology of electrical equipment and temperature measuring components, which is applied in the field of temperature measuring components and electrical equipment, can solve problems such as temperature rise, achieve good insulation, and shorten the effect of temperature measurement response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

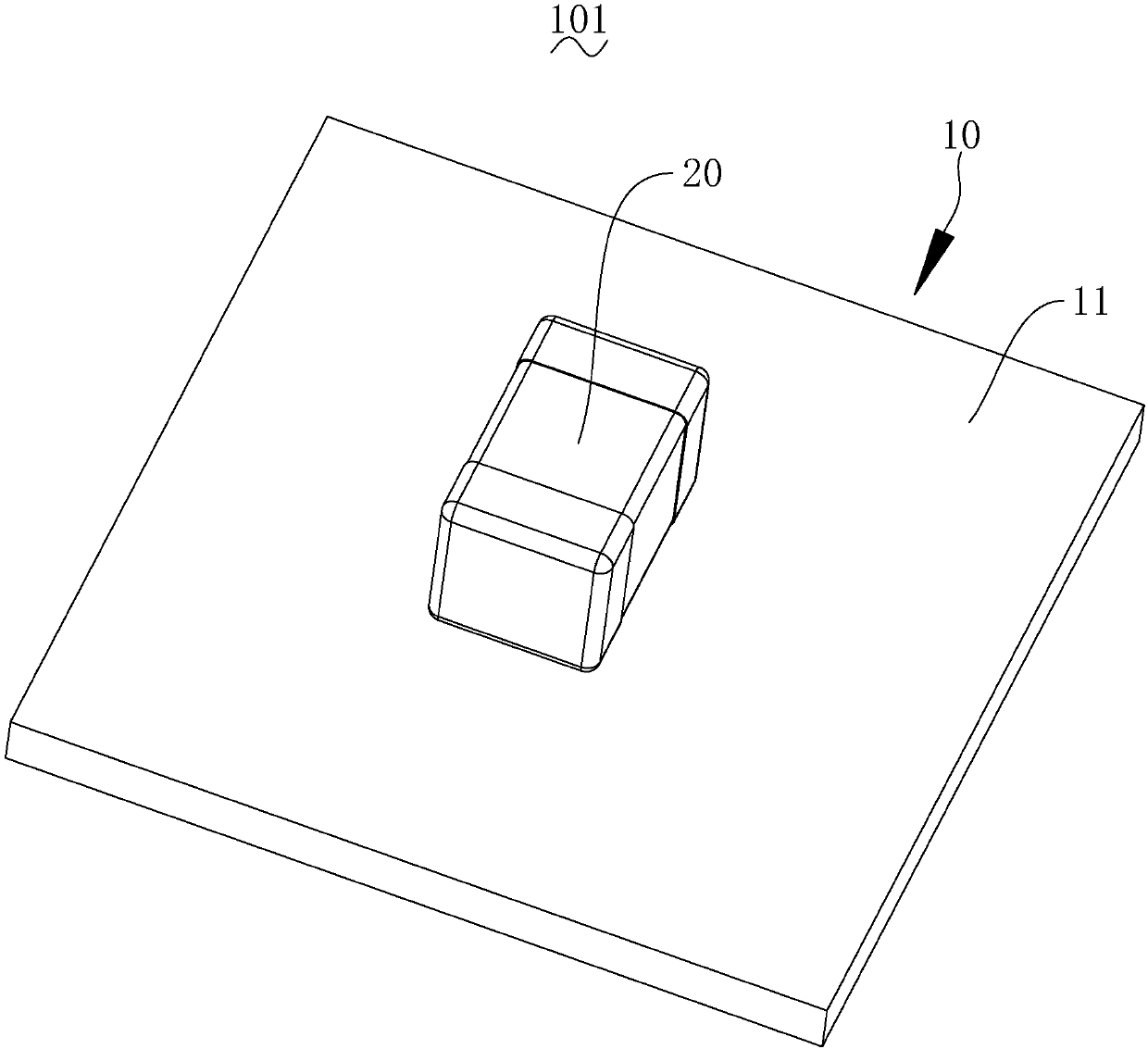

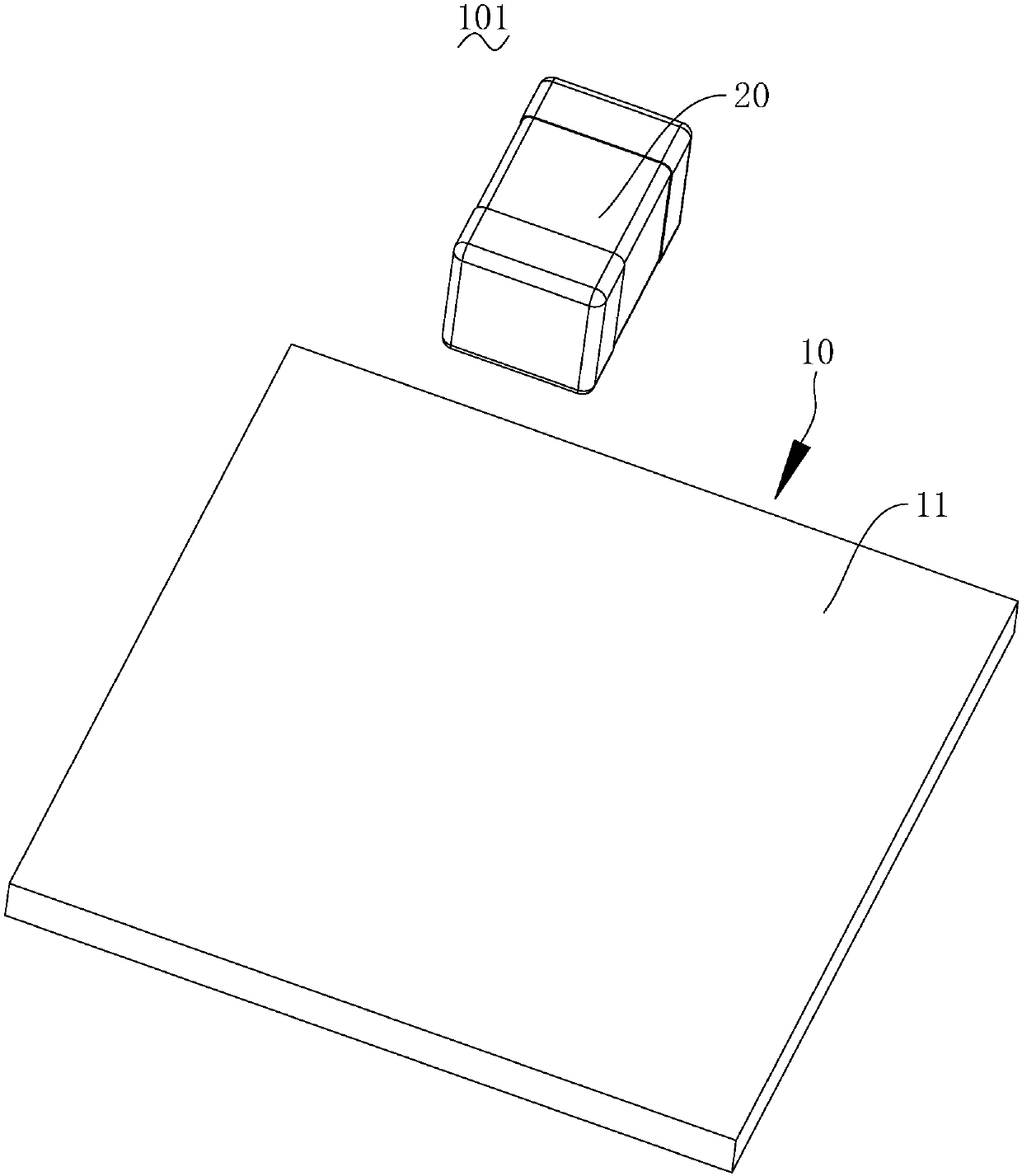

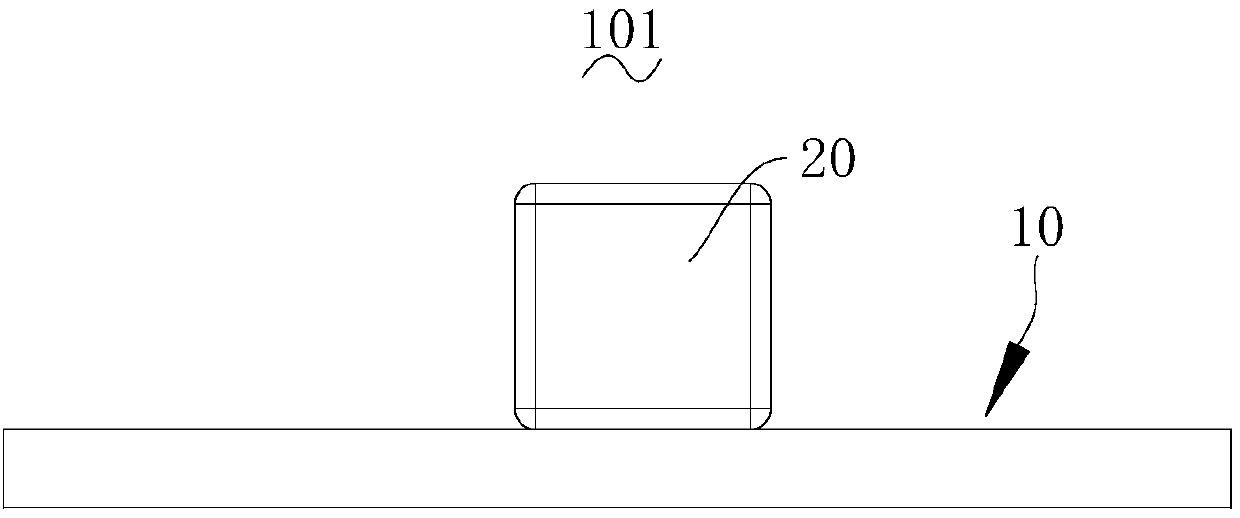

[0049] see Figure 1 to Figure 3 , which is a temperature measuring component 101 provided by the present invention. The temperature measuring component 101 includes a heat conducting element 10 and a temperature measuring element 20 . The heat conduction element 10 is used to conduct heat of the temperature-measuring device described below. The temperature-measuring element 20 and the heat-conducting member 10 are arranged in a heat-conductive manner, so as to measure the temperature of the temperature-measuring device. The heat conducting element 10 and the temperature measuring element 20 are separately and independently formed elements, and can be connected into one piece. That is to say, when they are not assembled together, the heat conducting element 10 and the temperature measuring element 20 are independent components and need to be manufactured separately.

[0050] The specific shape and surface area of the heat conducting element 10 are selected according to re...

Embodiment 2

[0054] see Figure 4 and Figure 5 , as a modification of the first implementation, it is a temperature measuring component 102 provided by the present invention. Different from Embodiment 1, the temperature measuring assembly 102 of this embodiment further includes an output connector 30 . The output connector 30 is electrically connected to the temperature measuring element 10 .

[0055] The output connector 30 is used to transmit the temperature signal measured by the temperature measuring element 10 . According to different temperature signal processing needs, the output connector 30 can be used for electrical connection with different temperature signal processing devices, such as a processor. In this embodiment, the output connector 30 is used for electrical connection with a BMS (Battery Management System, battery management system). The specific types and specifications of the output connector 30 only need to be able to output temperature signals. The output conne...

Embodiment 3

[0060] see Image 6 , as a modification of the second embodiment, it is a temperature measuring component 103 provided in the third embodiment. Different from the second embodiment, the temperature measurement assembly 103 in this embodiment further includes a sealing connection part 40 . The sealing connector 40 is in contact with the heat conducting element 10 and the temperature measuring element 20 respectively, and connects the heat conducting element 10 and the temperature measuring element 20 as a whole. That is to say, the sealing connecting member 40 only needs to enable the heat conduction member 10 and the temperature measuring element 20 to be connected together stably, and the part in contact with the sealing connecting member 10 can be sealed.

[0061] Preferably, the sealing connector 40 is arranged to cover and wrap the temperature measuring element 10 to seal the temperature measuring element 10 . The specific material and structure of the sealing connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com