Thin film capacitor for high-cooling electric vehicle

A technology for thin-film capacitors and electric vehicles, applied in thin-film/thick-film capacitors, capacitors, multilayer capacitors, etc., can solve the problems of large size, high cost, poor heat dissipation effect, etc., and achieve small size, low cost, and improved heat dissipation power. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

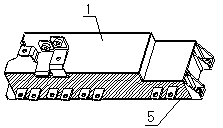

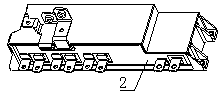

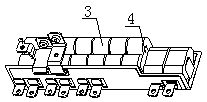

[0023] See Figure 1 to Figure 8 As shown, a film capacitor for electric vehicles with high heat dissipation includes a housing 1 and lead-out electrodes. A capacitor core 3 and a potting material 5 are arranged in the housing 1. The housing 1 is equipped with a cooling metal plate 12 at the bottom. The plastic shell 11 and the cooling metal plate 12 are used to connect with the cooling device inside the electric vehicle. It can be a cooling water pipe or an air-cooled radiator to effectively reduce the operating temperature of the capacitor. The capacitor core 3 is connected to the copper busbar 2 through the copper plate 4. The copper busbar 2 and the lead-out electrodes are formed as an integrated structure, the copper busbar 2 is arranged close to the cooling metal plate 12 , and insulating paper is arranged between the copper busbar 2 and the cooling metal plate 12 .

[0024] The potting material is epoxy resin with high thermal conductivity and low linear expansion coeff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com