An improved electric cooling and heating component driven by semiconductor temperature difference

A thermoelectric refrigeration and semiconductor technology, which is applied to the manufacture/processing of thermoelectric devices and thermoelectric devices that only use the Peltier or Seebeck effect. It can solve the problems of many processes, poor thermal conductivity, and low yield, and achieve a high thermal conductivity area. Large size, good thermal conductivity and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

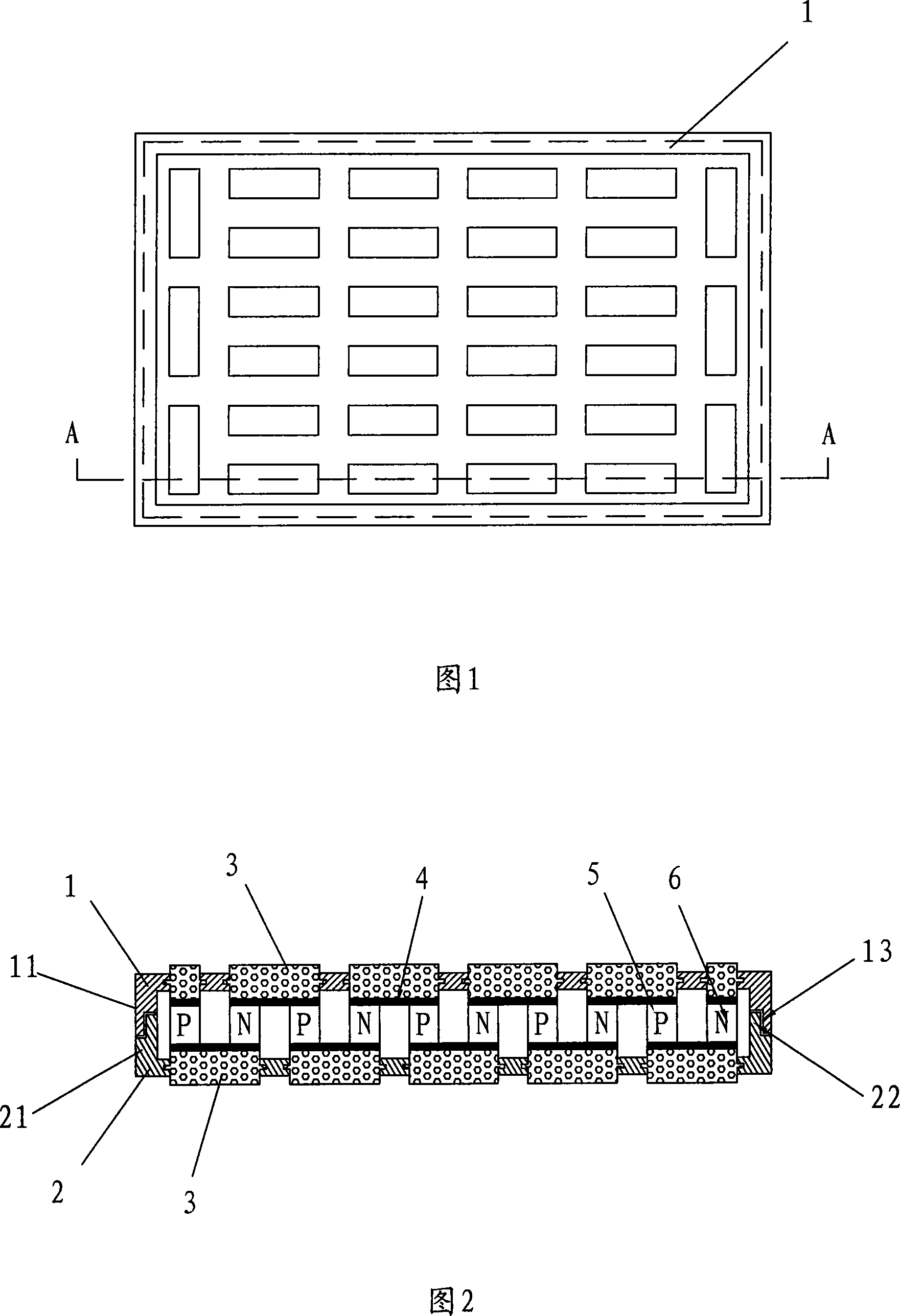

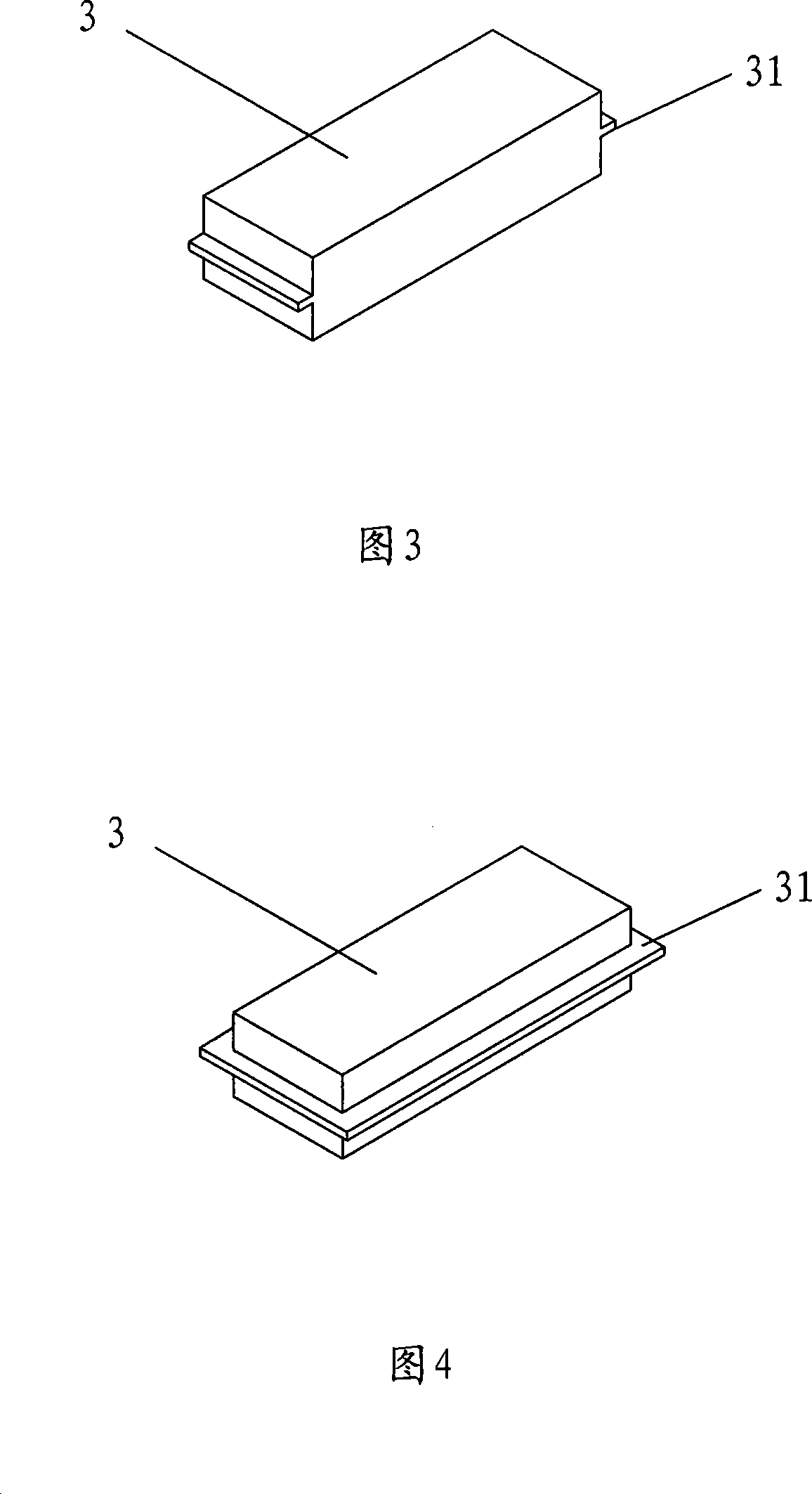

[0017] As shown in Figure 1 and Figure 2, an improved semiconductor thermoelectric cooling and heating assembly includes a conductive plate, a metal guide 3, a P-type couple 5, an N-type couple 6, and a metal guide and a P-type Solder layer 4 between galvanic couple and N-type galvanic couple. The conduction plate is divided into a cold end conduction plate 1 and a hot end conduction plate 2, so that the solder layer 4 connects the metal deflector 3 with the P-type couple 5 and the N-type couple 6 together, and the cold and hot ends made of plastic conduct The plates 1 and 2 are injection molded into one body with the metal guide vanes 3 respectively, and the metal guide vanes 3 protrude from the two ends of the cold and hot conduction plates 1 and 2 respectively.

[0018] A space is formed between the cold end conduction plate 1 and the hot end conduction plate 2, the periphery of the cold end conduction plate 1 has a lower edge plate 11, the periphery of the hot end conducti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com