Seat structure of diode illuminating device and method for manufacturing diode illuminating device

A light-emitting device and manufacturing method technology, applied in the direction of semiconductor devices, electric solid-state devices, electrical components, etc., can solve the problems of complicated process, poor heat dissipation efficiency, and increased heat dissipation area of the light-emitting diode packaging structure, and achieve high temperature resistance and increase The effect of increasing heat capacity, heat conduction area, and package reliability of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to have a further understanding of the purpose of the present invention, structural features and functions thereof, the relevant embodiments and accompanying drawings are described in detail as follows:

[0054]

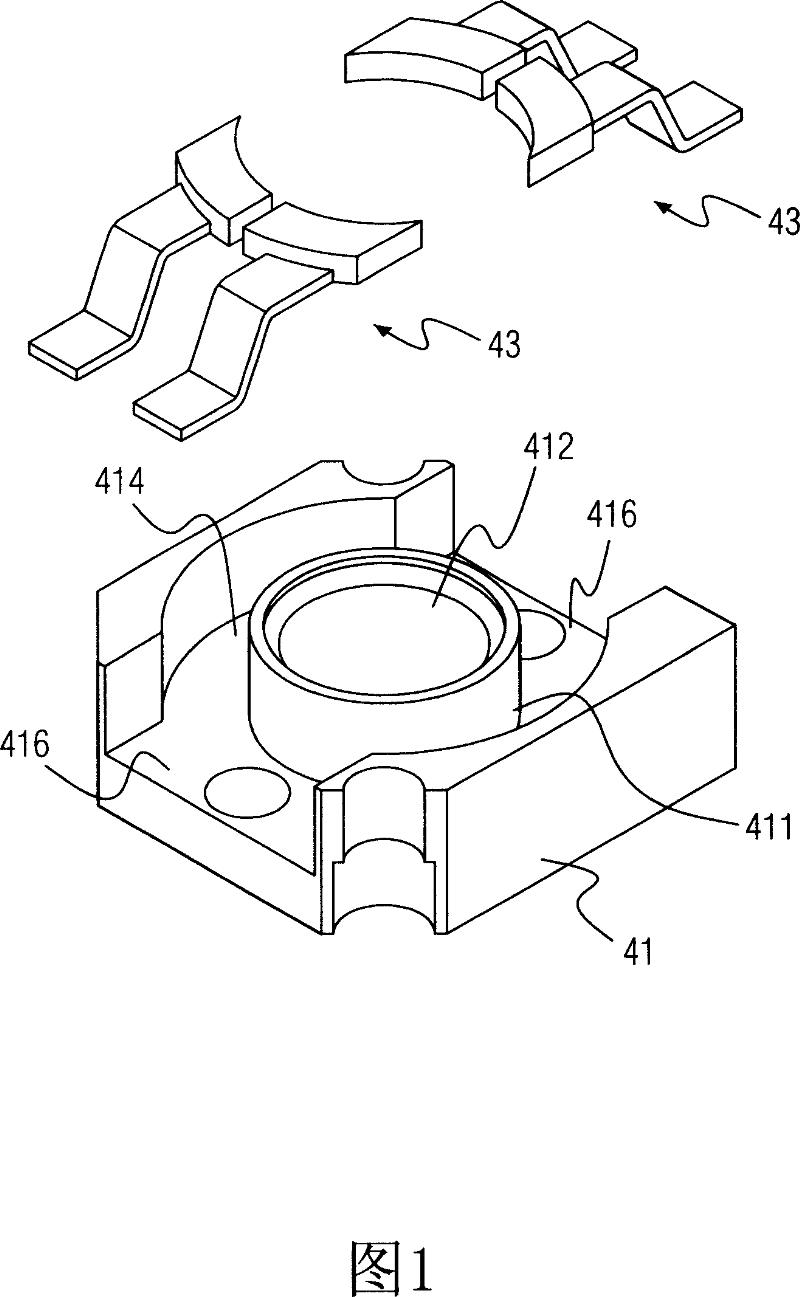

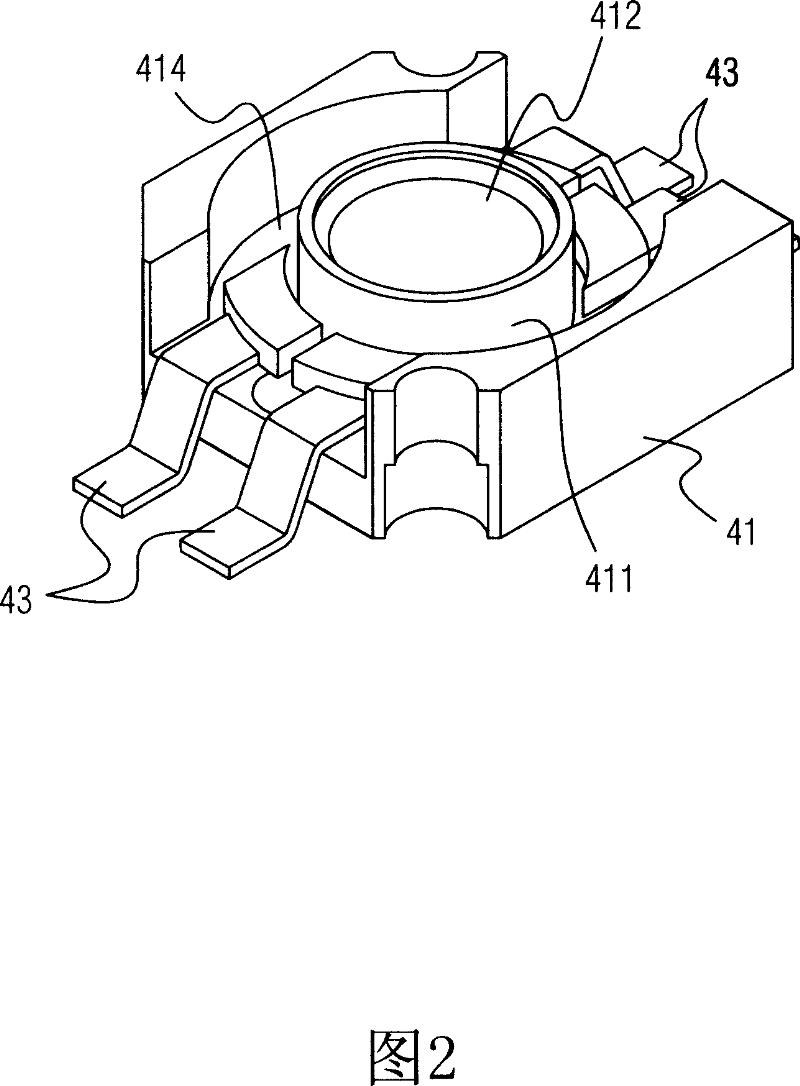

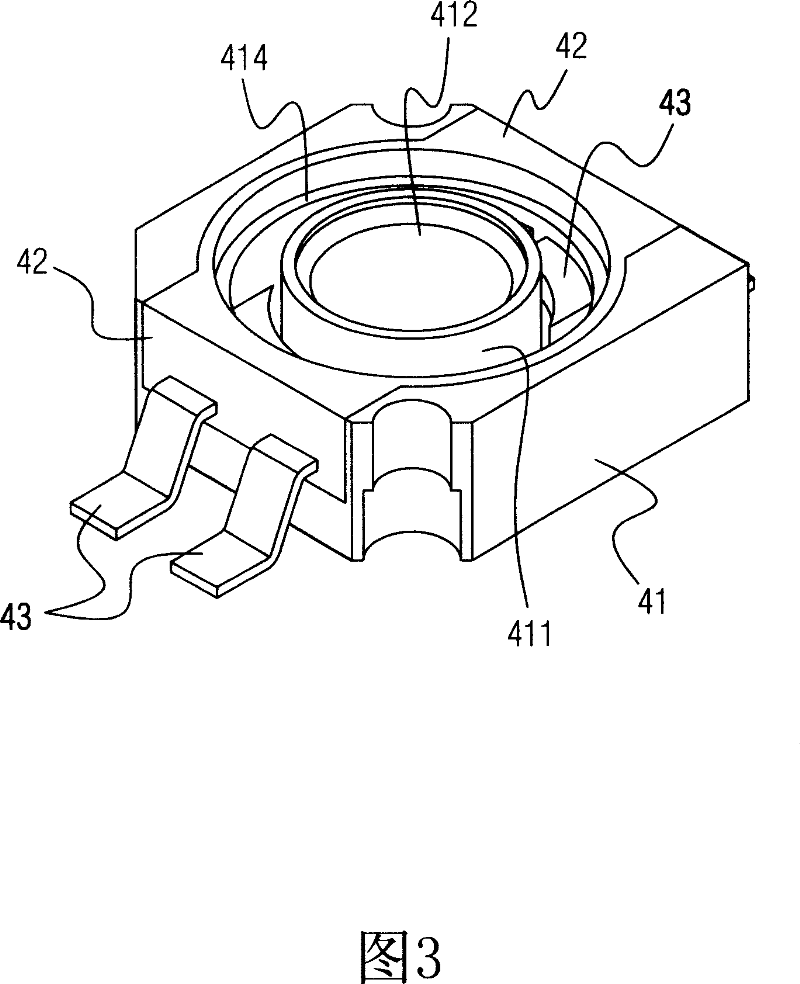

[0055] As shown in FIG. 1 , it is a three-dimensional exploded embodiment diagram of a heat conducting body 41 and a lead frame 43 with a first injection hole 417 but no second injection hole 418 according to the present invention. As shown in FIG. 2 , it is a diagram of an embodiment of the three-dimensional combination of the heat conducting body 41 with the first injection hole 417 but without the second injection hole 418 and the lead frame 43 of the present invention. As shown in FIG. 3 , it is a three-dimensional combination embodiment diagram of a heat conducting body 41 , a lead frame 43 and a plastic insulator 42 with a first injection hole 417 but without a second injection hole 418 according to the present invention. As shown in FIG. 4 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com