Integrated conductive anti-loose and anti-leakage fastener structure

A fastener and one-piece technology, applied in electrical components, antenna grounding switch structural connections, circuits, etc., can solve the problems of reduced antenna signal transmission efficiency, inability to take into account conductive functions, and inability to effectively complete grounding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

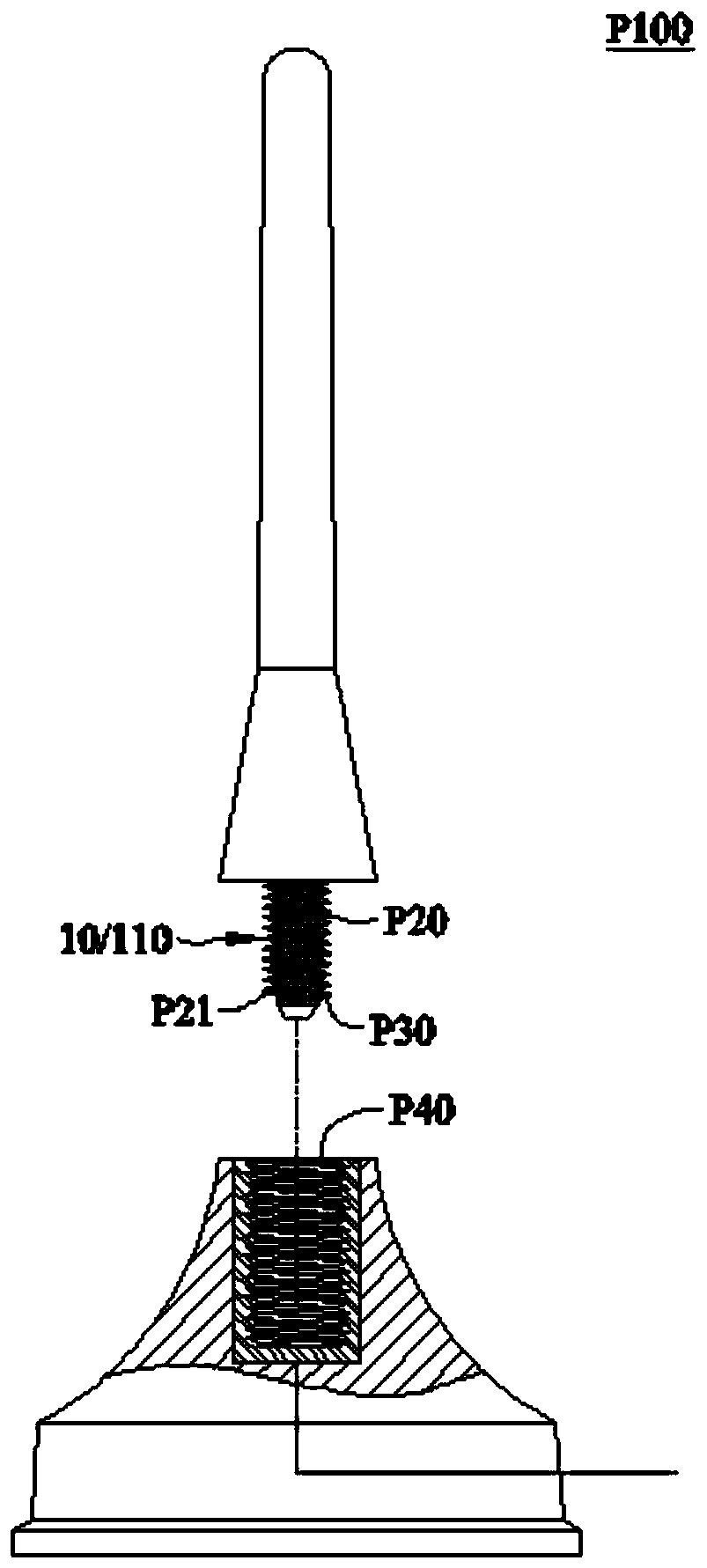

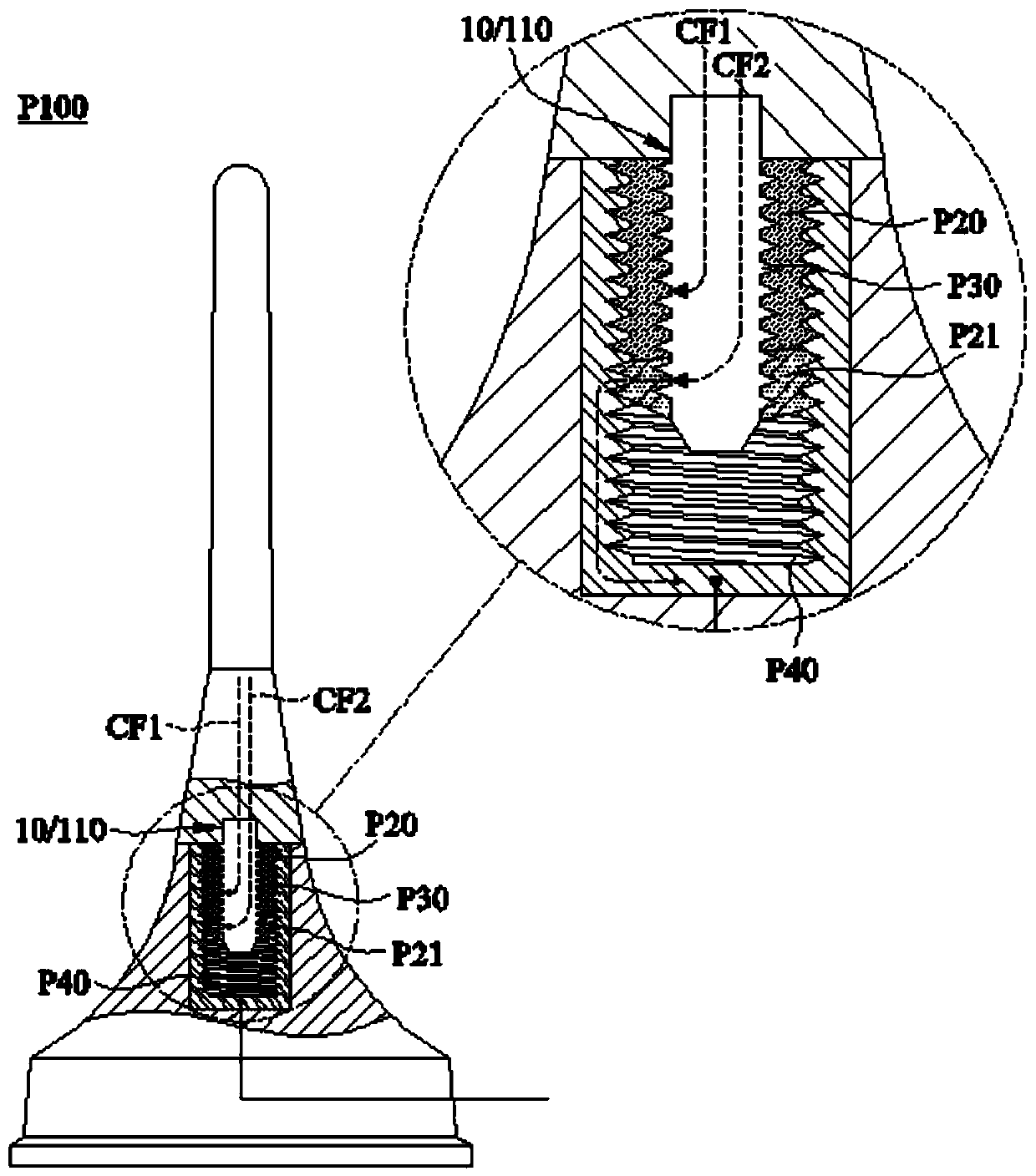

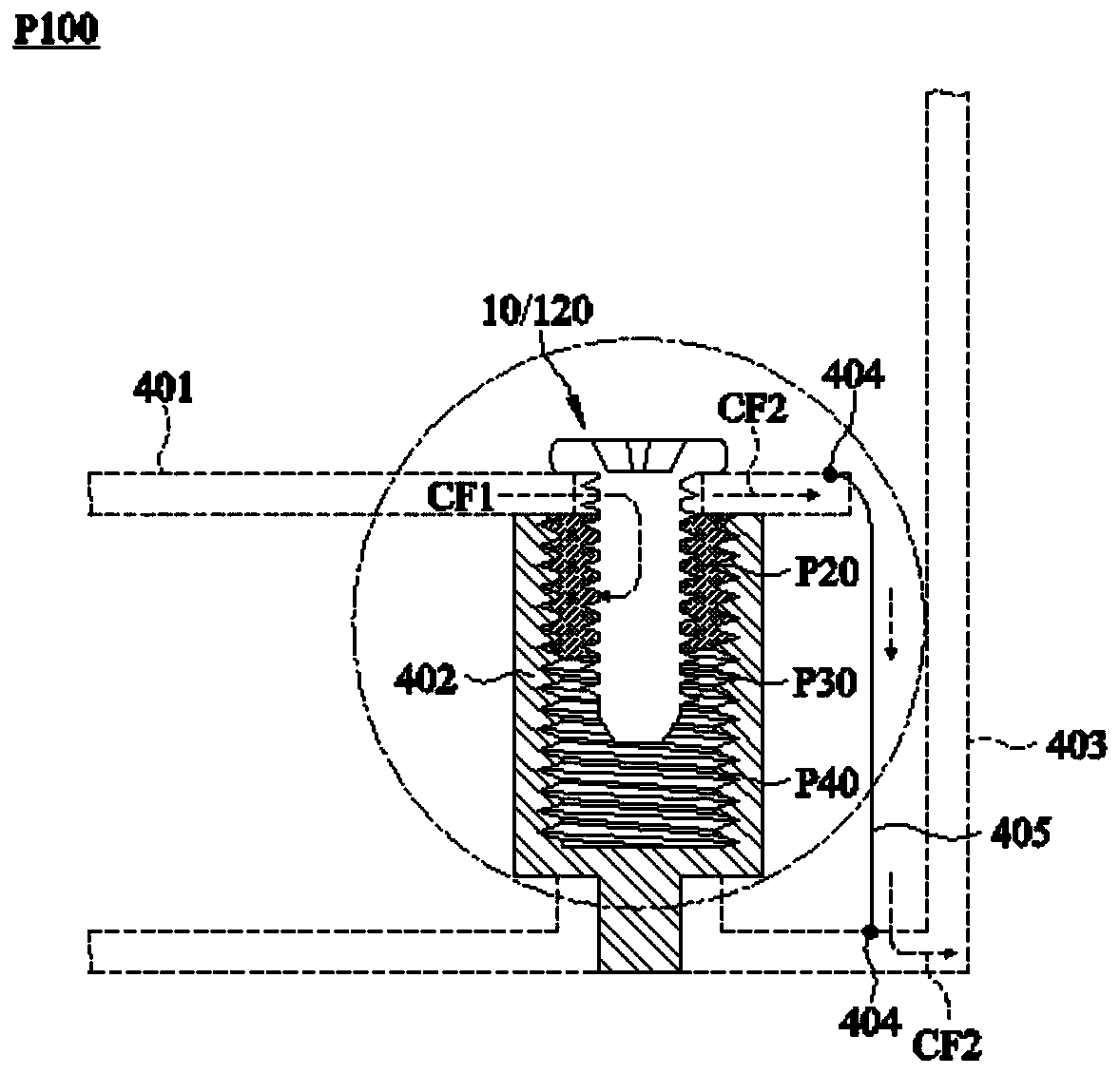

[0056] Such as Figure 5 , Figure 7 , Figure 9 and Figure 11 As shown, this embodiment provides an integrated conductive anti-loosening fastener structure 100 , which includes: a fastener 10 ; and a conductive anti-loosening structure 20 .

[0057] A fastener 10, which is a mechanical element that can mechanically fix one or more elements together, the fastener 10 can be, for example, an antenna solid 110 or a ground screw 120, etc., and the fastener 10 has a The surface, and part of the surface is a fastening contact surface.

[0058] Specifically, the fastening contact surface refers to the contact surface between the fastener 10 and the screw thread 140 of the base, that is, for example, the thread surface 130 or the seat surface of the antenna fastener 110 or the ground screw 120 .

[0059] The conductive anti-loosening structure 20 is formed on the fastening contact surface, that is to say, the conductive anti-loosening structure 20 is formed on the part or seat su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com