A method for the continuous preparation of samarium metal by direct thermal reduction

A direct and metallic technology, applied in the field of continuous preparation of samarium metal by direct thermal reduction, can solve the problems of short life of the reduction tank, high production cost, fast reaction speed, etc., achieve low reduction reaction time, fast reaction speed, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

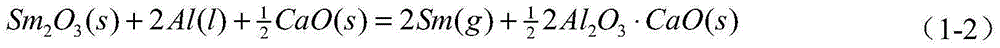

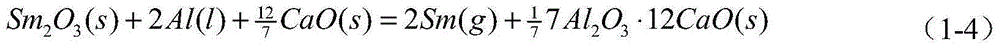

Method used

Image

Examples

Embodiment 1

[0040] The method for continuously preparing samarium metal by direct thermal reduction specifically comprises the following steps:

[0041] Step 1, ingredients into balls:

[0042] Ingredients: Sm 2 o 3 : Al according to the molar ratio of 1: 2.2 ingredients;

[0043] Pelletizing: Mix the ingredients evenly, and use a roller press at 100kg / cm 2 Pressed into spherical pellets under pressure;

[0044] Step 2, high temperature continuous reduction of pellets:

[0045] In a flowing argon gas atmosphere, the argon flow rate is 6.0m 3 / h, the pellets are continuously fed into the intermediate frequency induction furnace, the reduction temperature is 1400°C, and the reduction time is 60mins to obtain high-temperature samarium vapor, which is mixed with argon to form a high-temperature mixed gas, and the reduction slag is continuously discharged from the intermediate frequency induction furnace ;

[0046] Step 3, condensation of high temperature samarium vapor:

[0047] The h...

Embodiment 2

[0049] The method for continuously preparing samarium metal by direct thermal reduction specifically comprises the following steps:

[0050] Step 1, ingredients into balls:

[0051] Ingredients: Sm 2 o 3 : Al according to the molar ratio of 1: 2.0 ingredients;

[0052] Pelletizing: Mix the ingredients evenly, and use a roller press at 150kg / cm 2 Pressed into spherical pellets under pressure;

[0053] Step 2, high temperature continuous reduction of pellets:

[0054] In a flowing argon gas flow atmosphere, the argon flow rate is 4.5m 3 / h, the pellets are continuously fed into the intermediate frequency induction furnace, the reduction temperature is 1500°C, and the reduction time is 40 minutes to obtain high-temperature samarium vapor, which is mixed with argon to form a high-temperature mixed gas, and the reduction slag is continuously discharged from the intermediate frequency induction furnace ;

[0055] Step 3, condensation of high temperature samarium vapor:

[00...

Embodiment 3

[0058] The method for continuously preparing samarium metal by direct thermal reduction specifically comprises the following steps:

[0059] Step 1, ingredients into balls:

[0060] Ingredients: Sm 2 o 3 : Al according to the molar ratio of 1: 2.2 ingredients;

[0061] Pelletizing: Mix the ingredients evenly, and use a roller press at 250kg / cm 2 Pressed into spherical pellets under pressure;

[0062] Step 2, high temperature continuous reduction of pellets:

[0063] In a flowing argon gas flow atmosphere, the argon flow rate is 4.0m 3 / h, the pellets are continuously fed into the intermediate frequency induction furnace, the reduction temperature is 1600°C, and the reduction time is 30 minutes to obtain high-temperature samarium vapor, which is mixed with argon to form a high-temperature mixed gas, and the reduction slag is continuously discharged from the intermediate frequency induction furnace ;

[0064] Step 3, condensation of high temperature samarium vapor:

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com