Process for smelting magnesium by microwave heating Pidgeon process

A technology of microwave heating and microwave heating furnace, which is applied to the process of smelting magnesium by Pidgeon method and the field of microwave heating technology, can solve the problems of short service life, large energy consumption, easy to be oxidized, etc. The effect of improved heat utilization and uniform and rapid heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

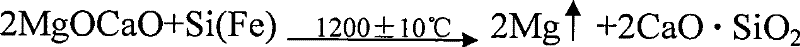

[0021] The technique of microwave heating Pidgeon process magnesium smelting of the present invention comprises the following steps:

[0022] 1. Calcining of dolomite: heating the dolomite to 1100-1200°C in a rotary kiln, shaft kiln or sleeve kiln, and burning it into calcined white (MgOCaO);

[0023] 2. Batching and making pellets: Calcined white, ferrosilicon powder and fluorite powder are measured, batched and ground, and then pressed into pellets that meet the process requirements; Ratio of ingredients;

[0024] 3. Place the pellets in a closed non-metallic reduction tank in a microwave heating furnace, start the microwave heating furnace to heat the pellets, the heating temperature is between 1000°C and 1200°C, so that the magnesium compound in the pellets and ferrosilicon The powder reacts, and the metal magnesium produced by the reaction exists in the form of magnesium vapor; the optional temperature is 1000°C, 1050°C, 1100°C, 1130°C, 1150°C, 1180°C, 1200°C, etc.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com