Air cooling device for large cover of titanium sponge I-type reactor

An air-cooling device and reactor technology, applied in the field of sponge titanium equipment manufacturing, can solve the problems of shortened reduction reaction time, high safety factor, shortened service life, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

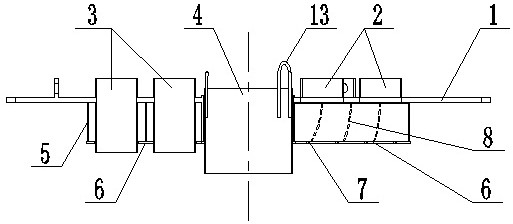

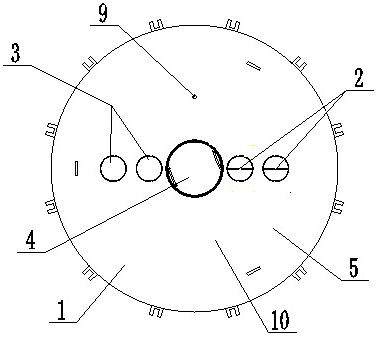

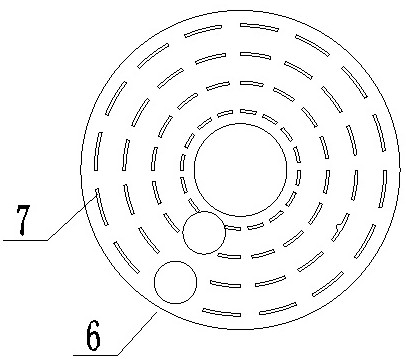

[0024] as Figures 1 through 3 As shown, an air-cooled apparatus for a large cover of a sponge titanium I-type reactor, comprising a cover plate 1, the left and right of the cover plate is distributed with an air-cooled area, wherein one air-cooled area is provided with an air inlet 2, another air-cooled area is provided with an air outlet 3, the middle of the cover plate 1 is provided with an inlet 4, the lower part of the cover plate 1 is installed by the cloth plate 6, the inlet port 4 and the air outlet 3 runs through the cloth air plate 6, the air inlet 2 is located above the cloth plate 6, The air distribution plate 6 is uniformly provided with a cloth plate outlet 7, the upper side of the air distribution plate 6 and the cover plate 1 on the lower side of the air inlet 2 is provided vertically with a deflector plate 8, the bottom of the cover plate 1 is provided with a temperature port 9.

[0025] When the temperature measuring port 9 of the measured reactor large cover 11 w...

Embodiment 2

[0027] as Figures 1 through 6As shown, an air-cooled device for the large cover of the sponge titanium I-type reactor, comprising a cover plate 1, the cover plate 1 bolt is bolted to the upper side of the reactor cover 11, the left and right of the cover plate is distributed with an air-cooled area, wherein one air-cooled area is provided with an air inlet 2, another air-cooled area is provided with an air outlet 3, the middle of the cover plate 1 is provided with an inlet 4, the inlet port 4 corresponds to the feeding port of the reactor large cover 11, and the active windshield ring 12 is provided at the feeding port of the reactor large cover 11, Not only is the reactor large cover 11 may occur of high temperature deformation adapted, and can not let the wind in the air duct come out from the middle thereby reducing the cooling effect, in order to better seal the effect, it is also possible to fill the outside of the active wind shield 12 with thermal insulation, the cover plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com