Technology for producing and reducing ilmenite using rotary kiln

A process method and ilmenite technology are applied in the field of rotary kiln production of reduced ilmenite, which can solve the problems of difficult control of temperature and temperature uniformity, long production cycle, and low production efficiency, so as to shorten the reduction reaction time, The effect of stable product quality and simplified production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

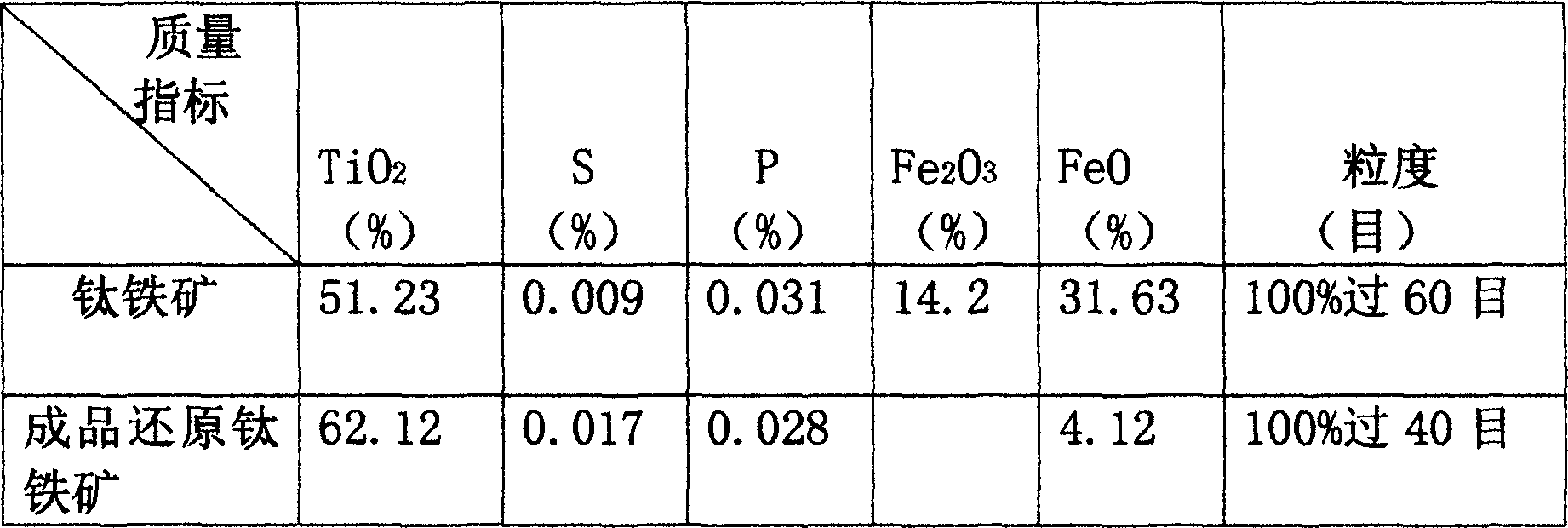

Image

Examples

Embodiment 1

[0008] a. Raw material preparation

[0009] Pass the ilmenite through a 60-mesh vibrating sieve. The reducing agent coal ash is crushed and screened to remove powdery materials. The weight ratio of reducing agent coal ash to ilmenite is 0.4:1, and the weight ratio of desulfurizing agent lime to reducing agent coal ash is 0.1:1.

[0010] b. Restore

[0011] When the temperature of the high-temperature zone in the kiln rises to 900°C, start to add the raw materials in a to the kiln, adjust the rotary kiln speed, raise the temperature and stabilize the temperature of the high-temperature zone in the kiln between 1120-1150°C, and control the reduction rate above 85%. , The reducing atmosphere pressure is kept between +1~+3mm water column.

[0012] c. cooling

[0013] When the material is about to reach the kiln head of the reduction rotary kiln, the cooling water for cooling the rotary kiln is turned on to cool the material to below 50°C.

[0014] d. Screening, magnetic separ...

Embodiment 2

[0019] The weight ratio of reducing agent coal ash to ilmenite is 0.3:1, and the weight ratio of desulfurizing agent lime to reducing agent coal ash is 0.08:1. When the temperature of the high temperature zone in the kiln rises to 900°C, start to add raw materials into the kiln, adjust the rotary kiln speed, raise the temperature and stabilize the temperature of the high temperature zone in the kiln at 1050-1120°C for reduction. Other process conditions are identical with embodiment one.

Embodiment 3

[0021] The weight ratio of reducing agent coal ash to ilmenite is 0.6:1, and the weight ratio of desulfurizing agent lime to reducing agent coal ash is 0.15:1. When the temperature of the high-temperature zone in the kiln rises to 900°C, start to add raw materials into the kiln, raise the temperature and stabilize the temperature of the high-temperature zone in the kiln at 1130-1150°C for reduction. Other process conditions are identical with embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com