Patents

Literature

56results about How to "Increase the number of settings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

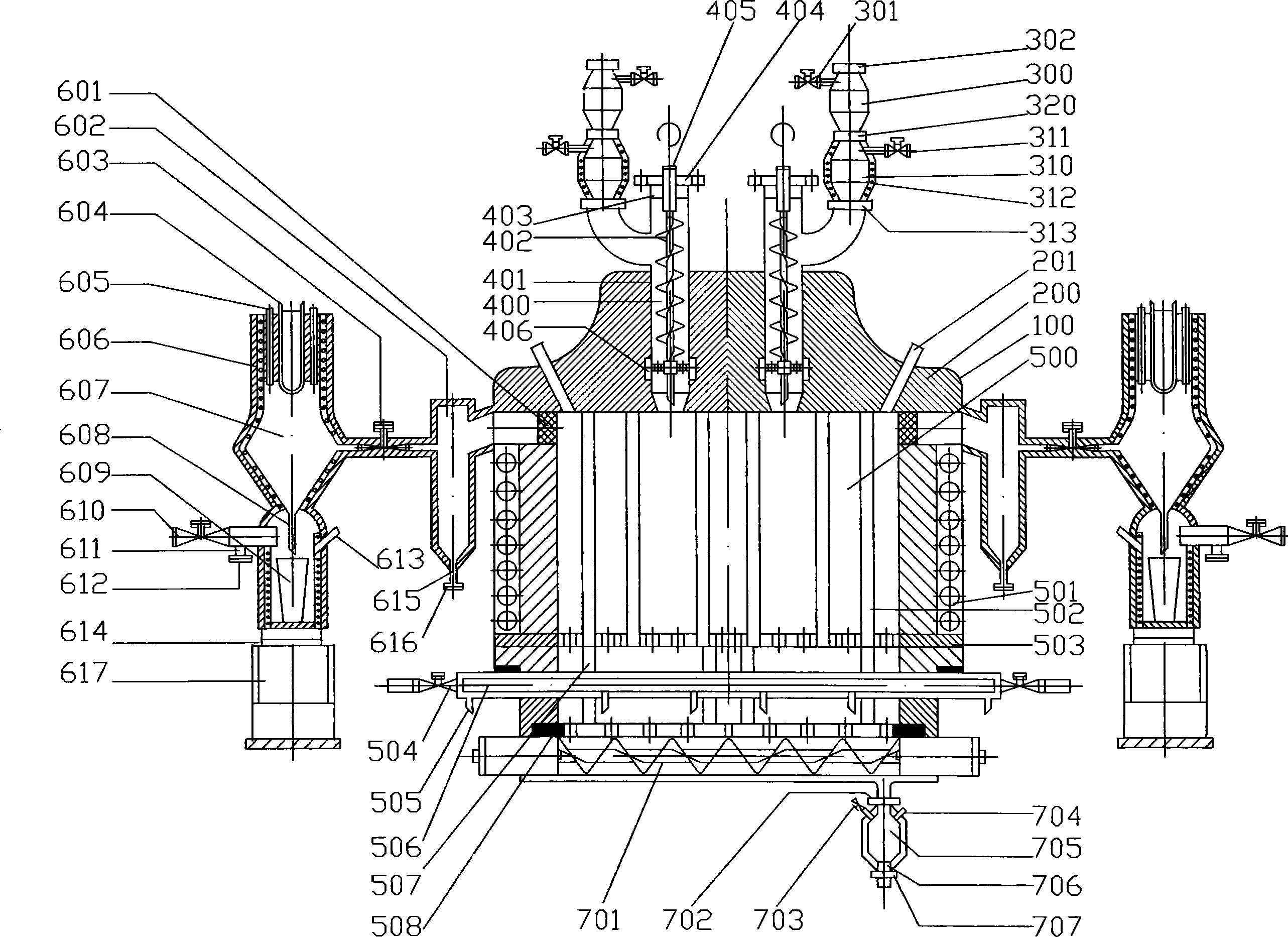

Induction heating continuous magnesium-smelting system and continuous magnesium-smelting technique

The invention discloses a system of inductive heating continuous magnesium smelting and a continuous magnesium smelting technique. The system comprises a continuous feeding device, an inductive heating reaction chamber, a magnesium steam condensing device and a continuous discharging device; wherein the feeding device consists of a feeding housing and a spiral feeding mechanism, the reaction chamber comprises an inductive heating winding, a heating element, a clapboard with holes and a slag cooling device, the condensing device consists of a mesh clapboard, a dust deposition chamber, the magnesium steam condensing chamber, the continuous discharging device comprises spiral slag discharging mechanism and slag housing. The continuous magnesium smelting technique consists of the processes of the continuous feeding of reacting burden into the reaction chamber, the continuous condensation of the magnesium steam and the discharge of liquid magnesium, and also comprises steps of the continuous feeding of reacting slag into the slag housing and slag discharging. The invention has high heat energy utilization rate, and can realize the low cost continuous production of the metal magnesium.

Owner:CENT SOUTH UNIV

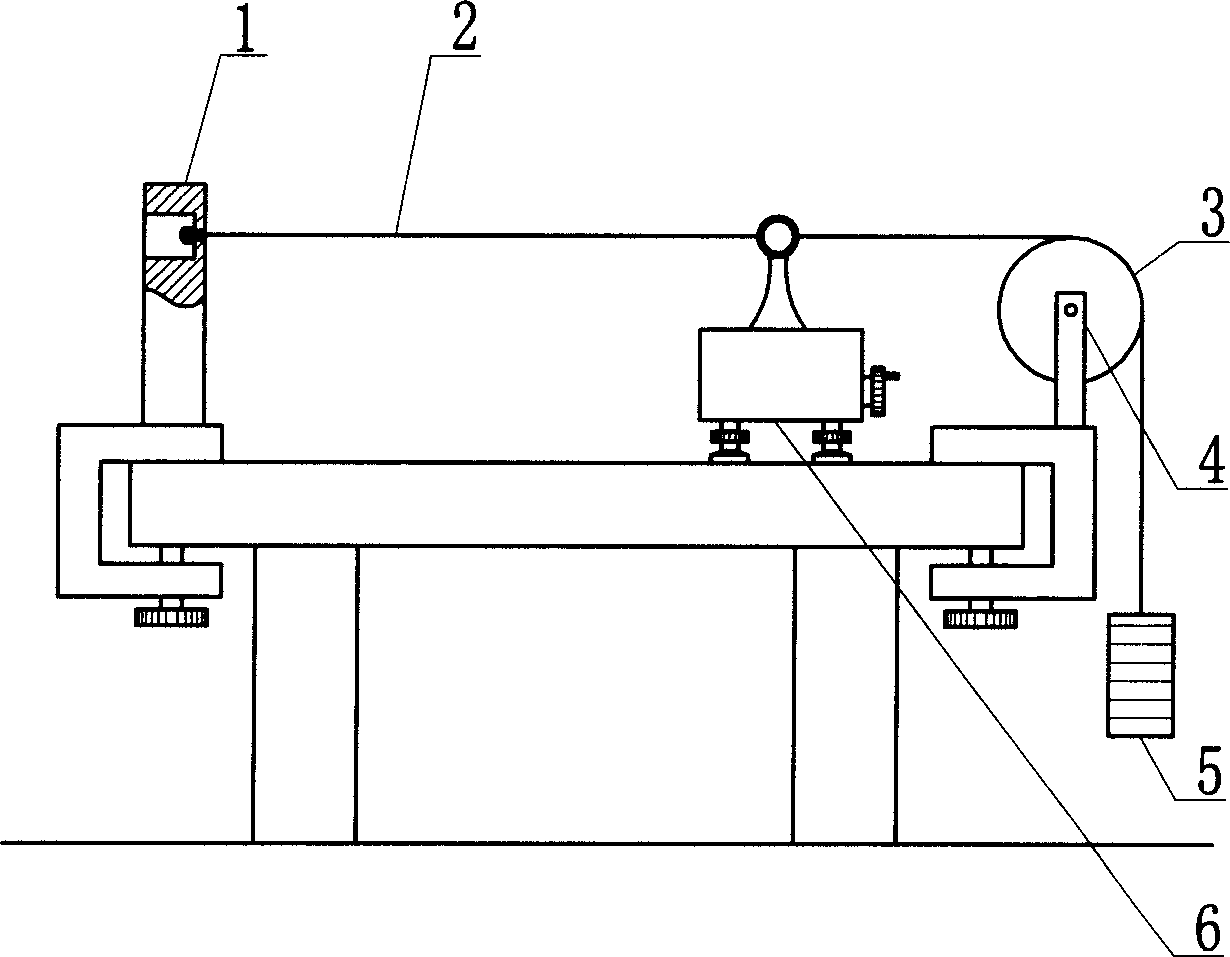

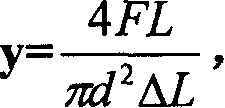

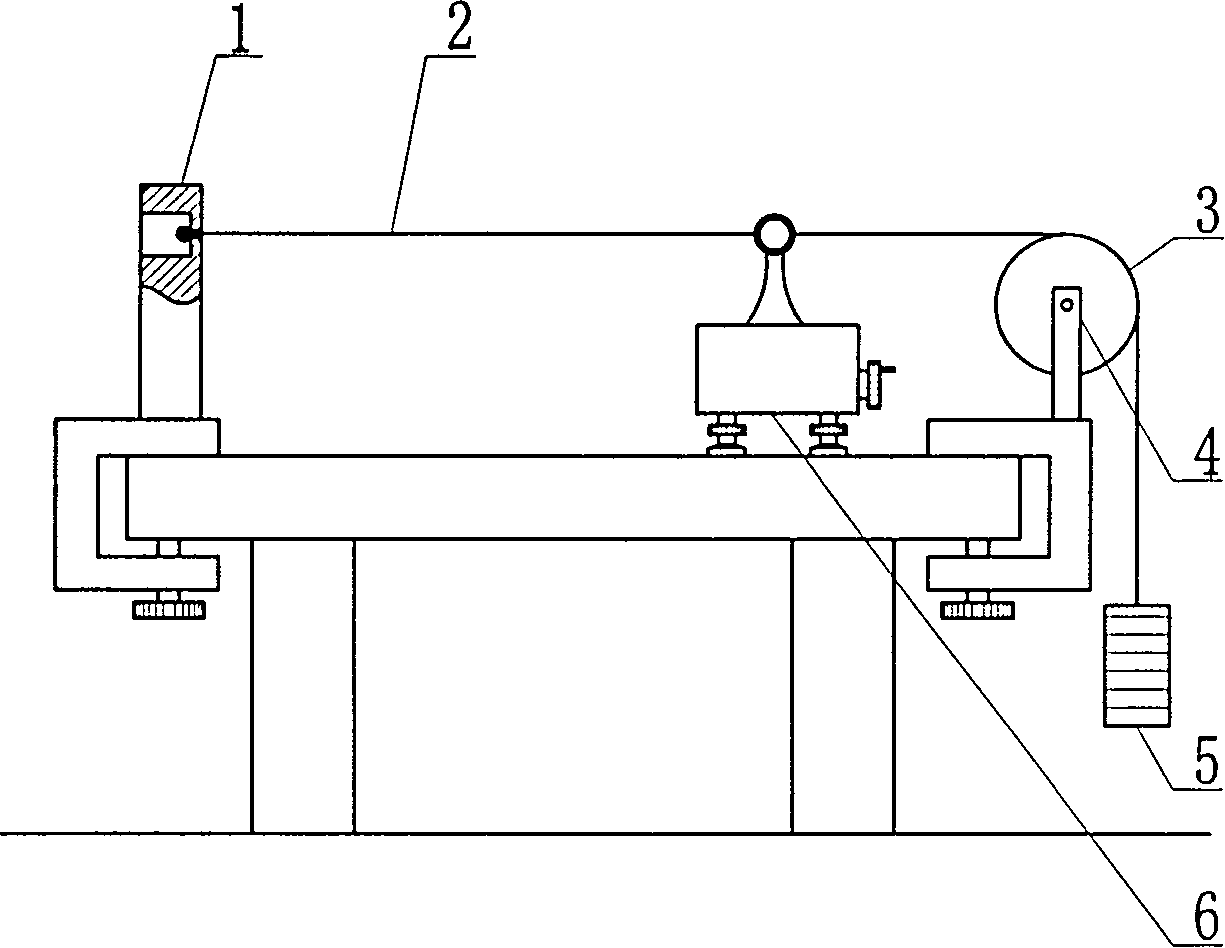

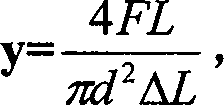

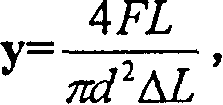

Horizontal type measuring apparatus for Young's modulus

InactiveCN1696644AIncrease the number of setsIncrease profitMaterial analysis by optical meansMaterial strength using tensile/compressive forcesSystem errorMicroscope

A horizontal Youngí»s modulus measurer can measure Youngí»s modulus of steel wire conveniently by applying horizontal drawing method and utilizing the reading microscope. The present invention decreases two moduluses to be tested, so measurement and calculation are simplified and system error of measurement can be decreased.

Owner:SICHUAN UNIV

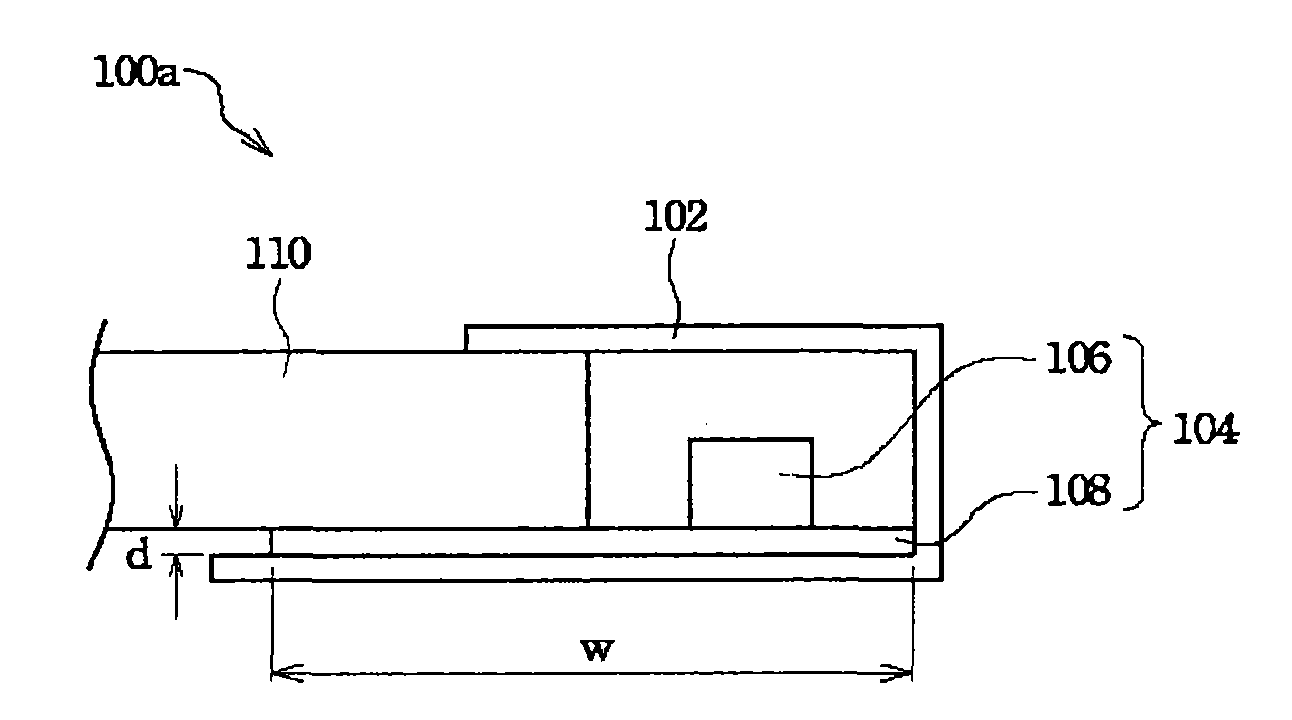

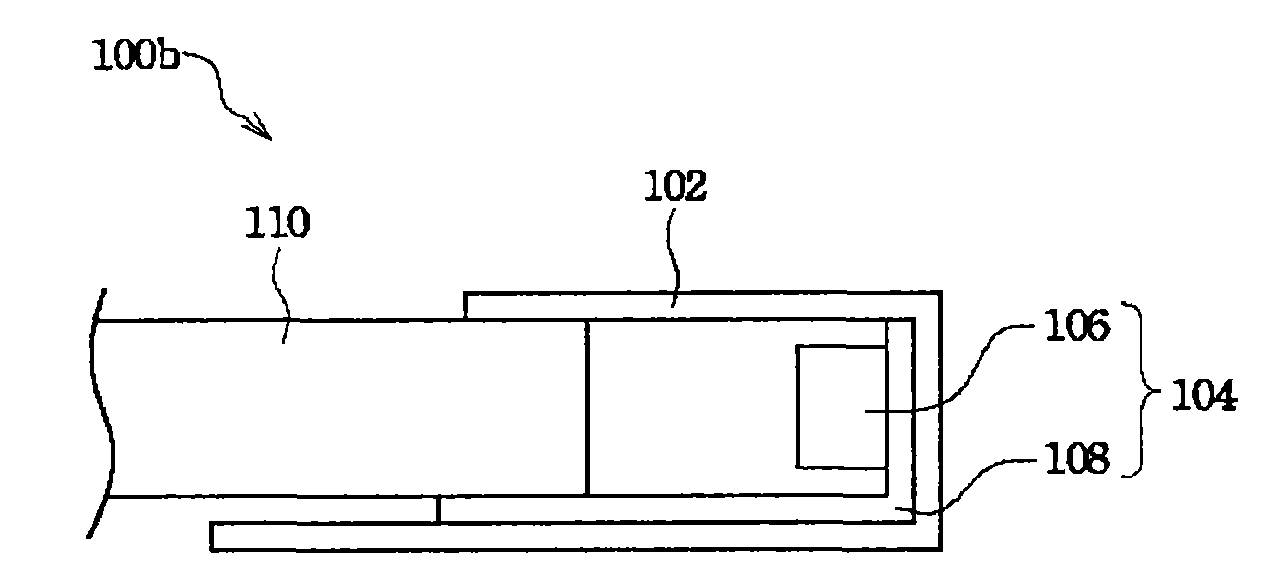

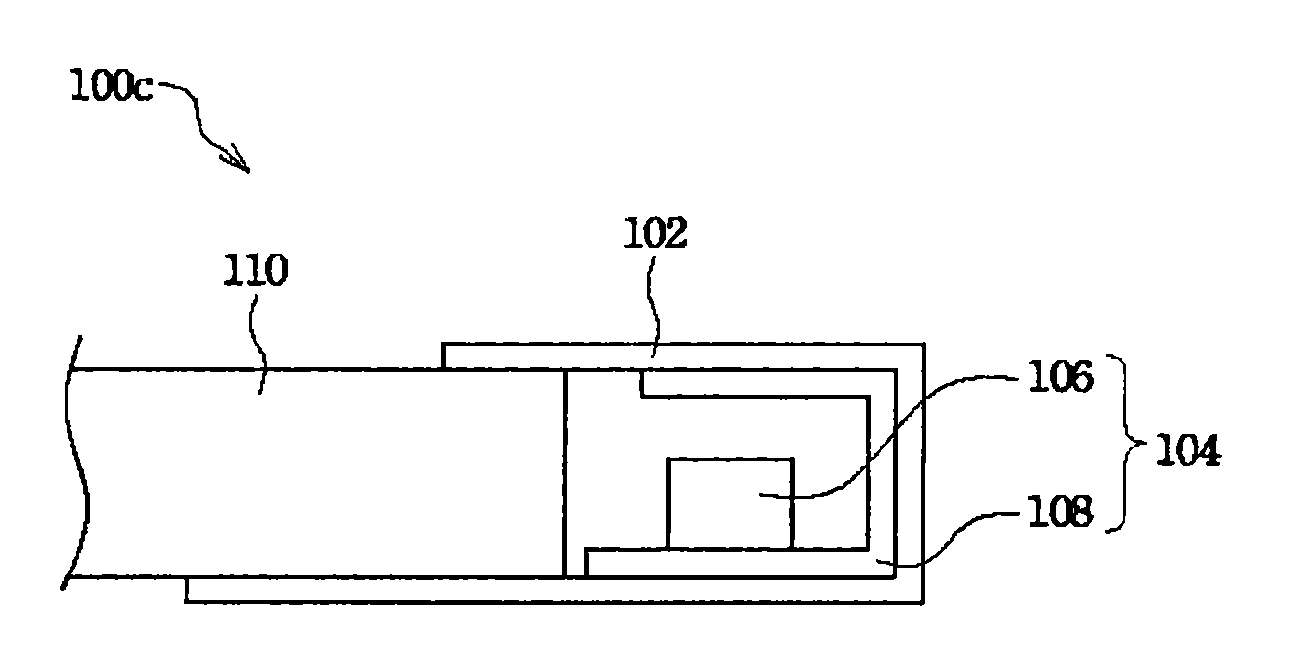

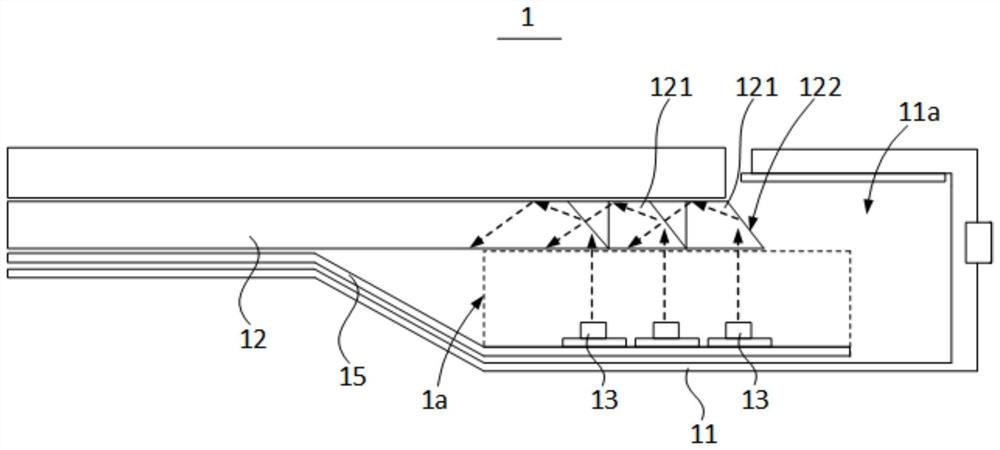

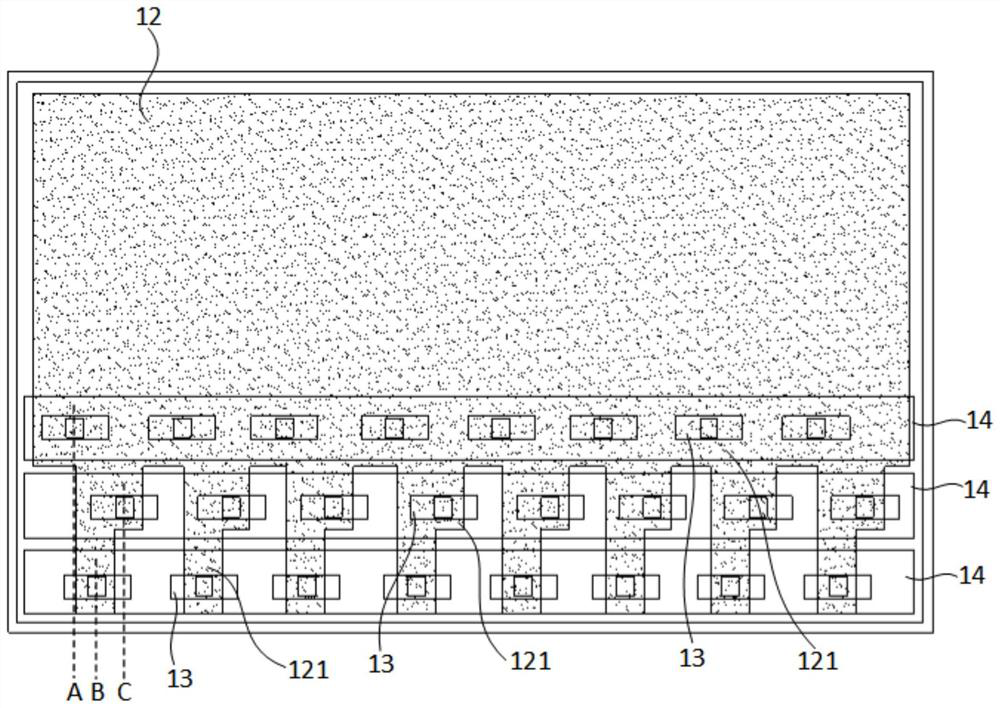

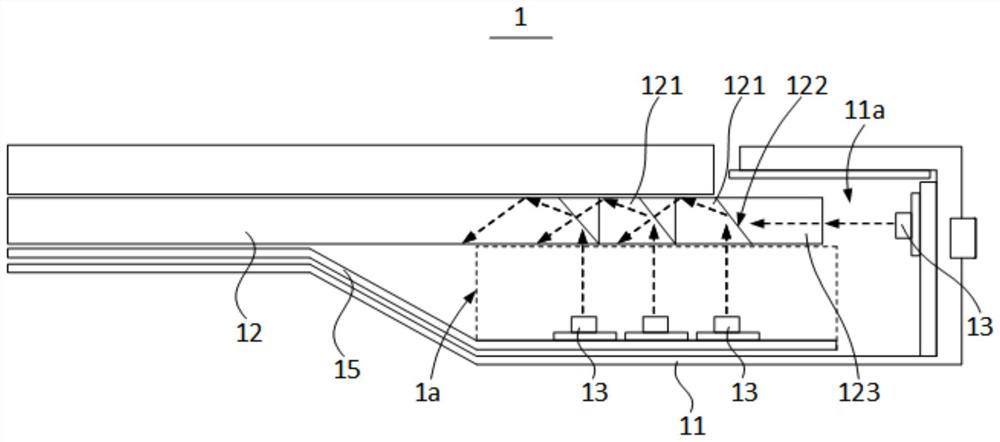

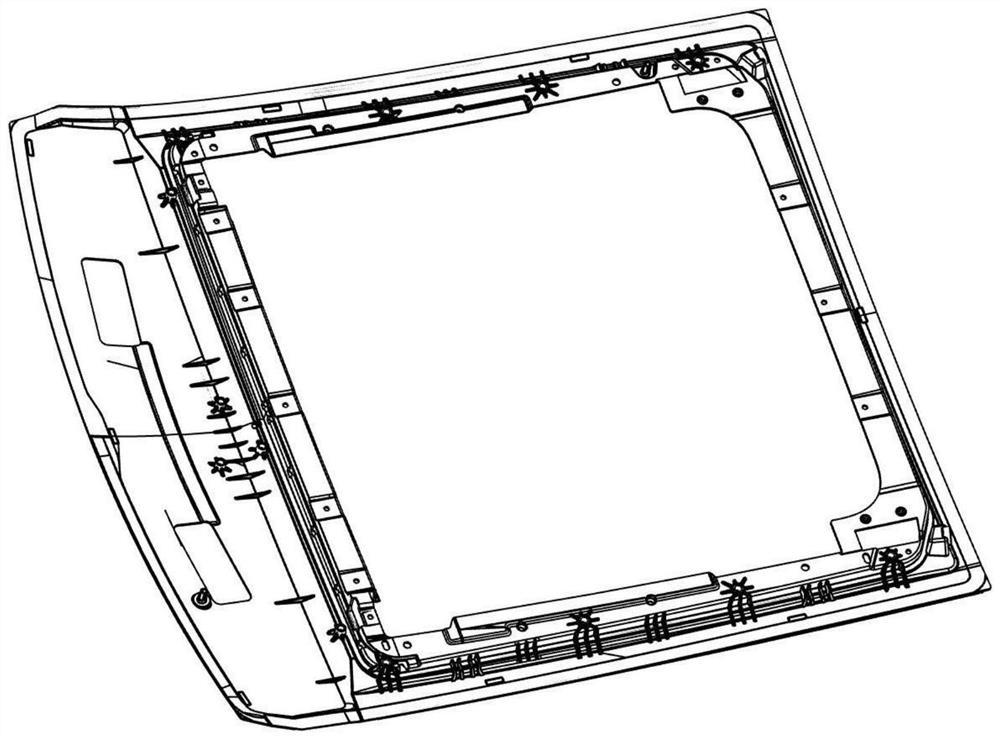

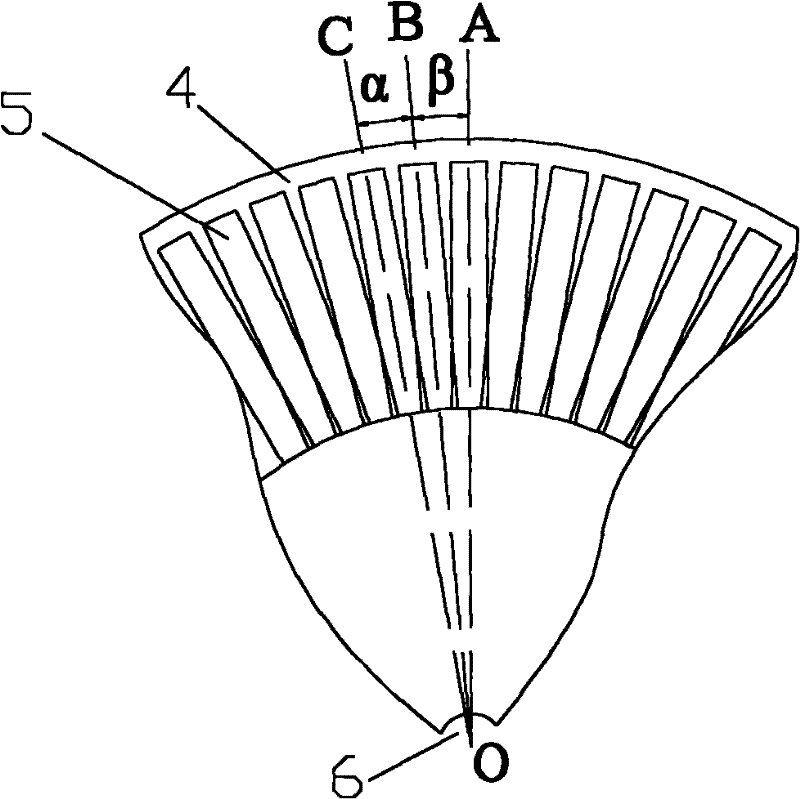

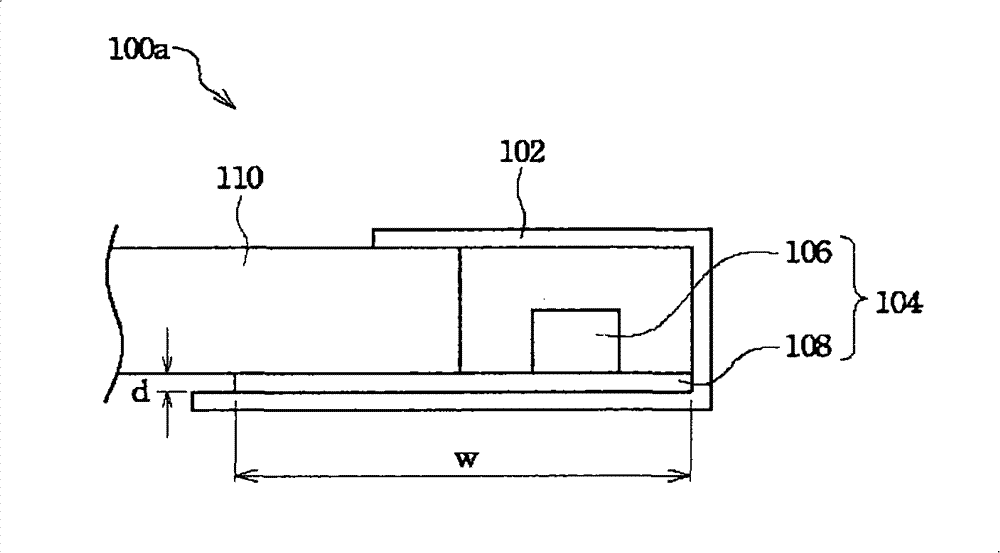

Backlight module, assembly method thereof and liquid crystal display using backlight module

InactiveCN101630091AIncrease layout spaceReduce difficultyLighting support devicesElectric circuit arrangementsLiquid-crystal displayLight guide

The invention discloses a backlight module, an assembly method thereof and a liquid crystal display using the backlight module. The backlight module at least comprises: a light guide panel; a shell which clamps the light guide panel and forms an accommodating space with the light guide panel; at least one light emitting diode light bar arranged in the accommodating space and provides at least onelight beam that enters the light guide panel. The light emitting diode light bar at least comprises a flexible circuit board and a plurality of light emitting diodes; and the flexible circuit board at least comprises a first part and at least two second parts, wherein the light emitting diodes are arranged on the first part of the flexible circuit board and the second parts are overlapped with each other. The difficulties in the assembly of the backlight module can be reduced.

Owner:INNOLUX CORP

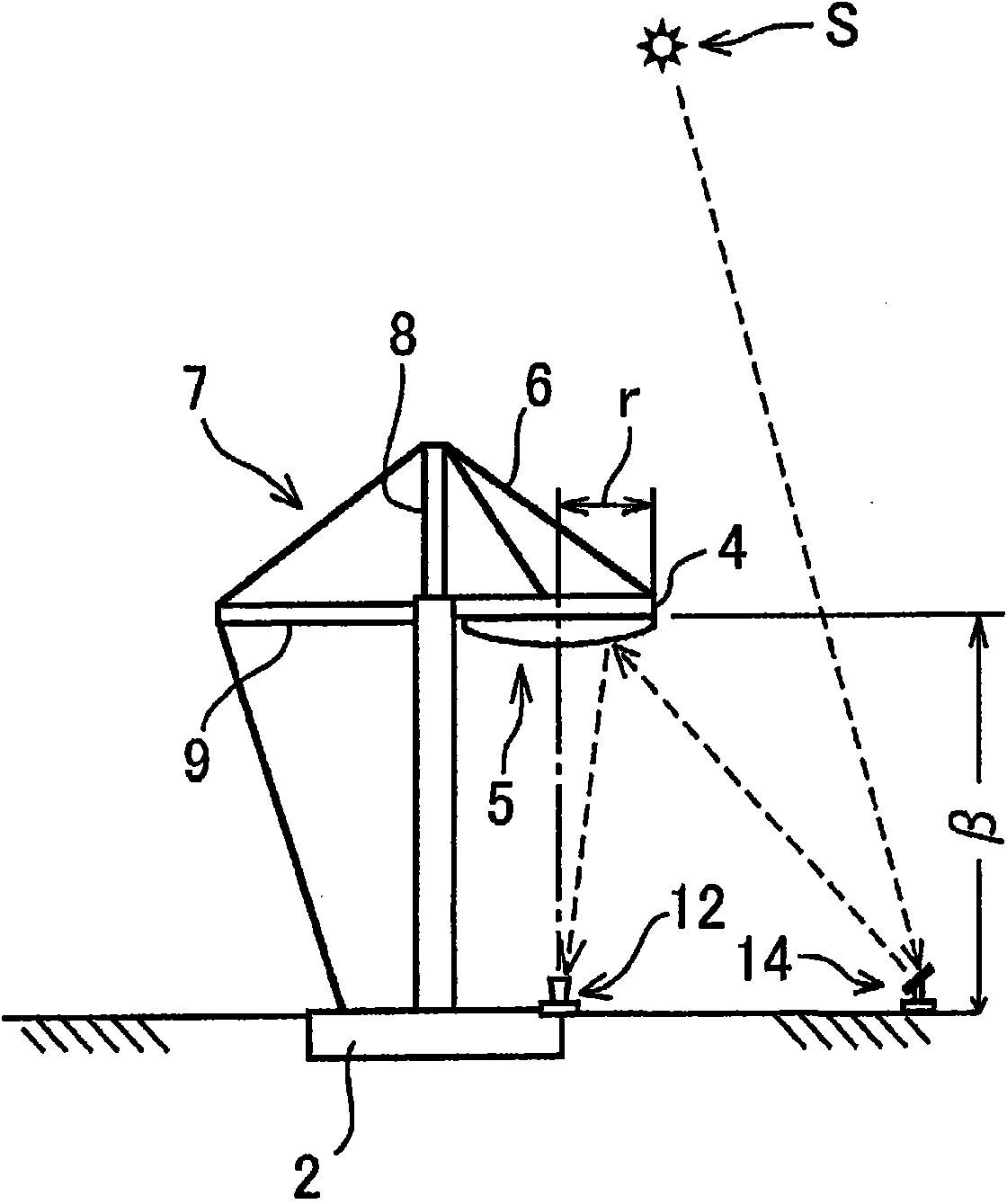

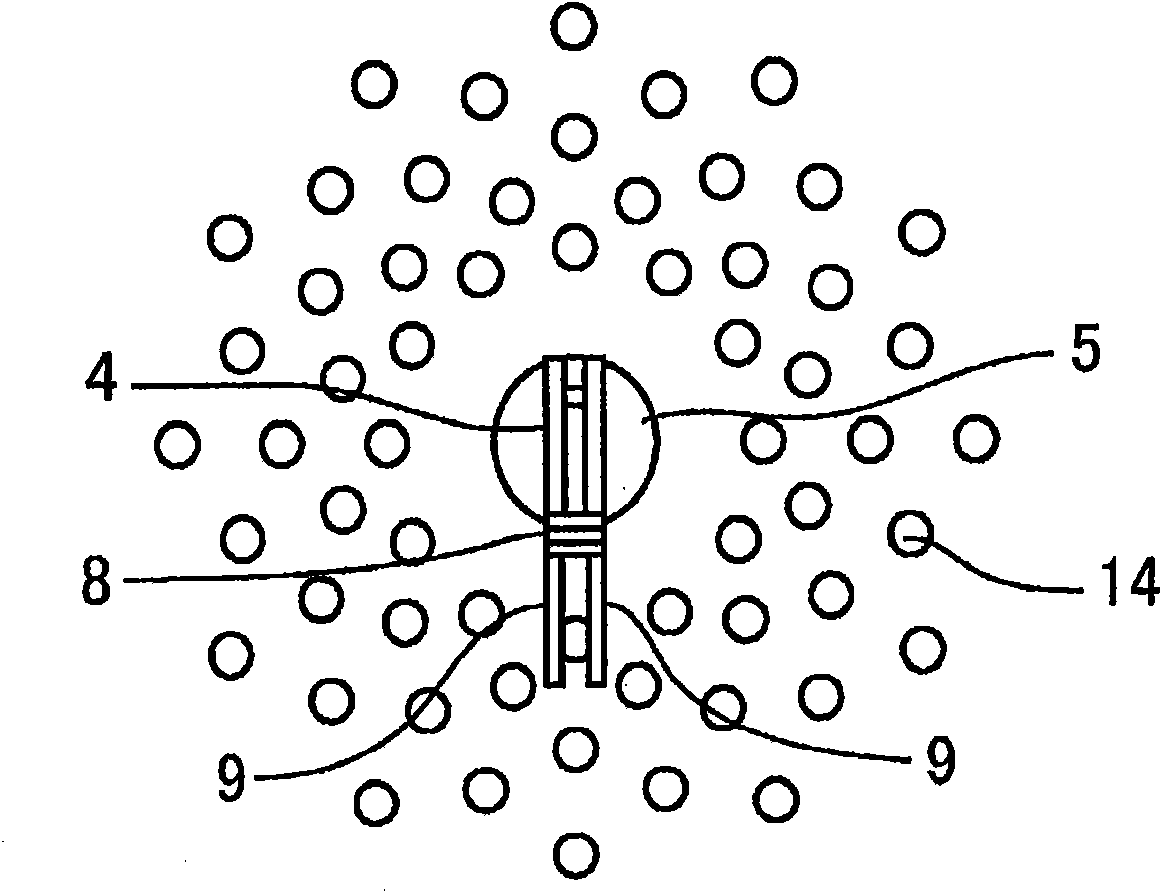

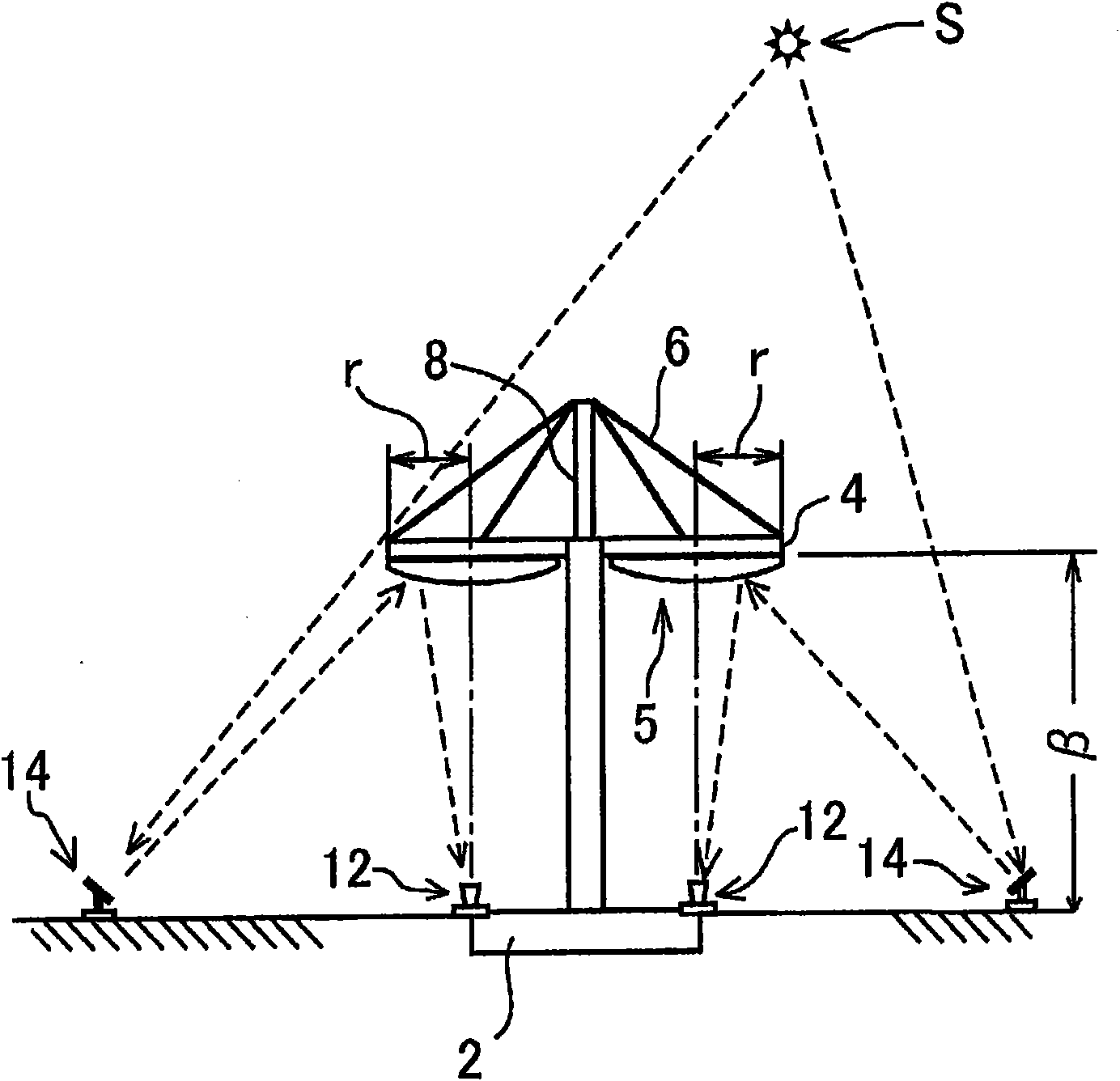

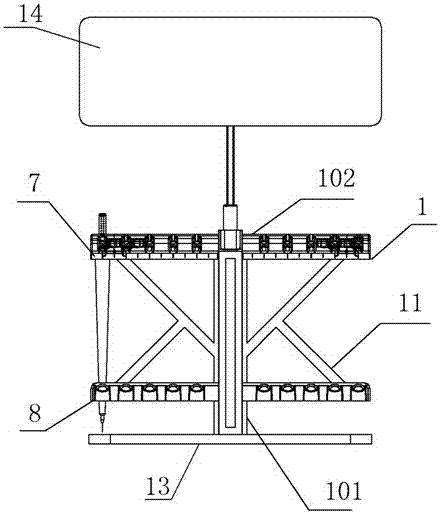

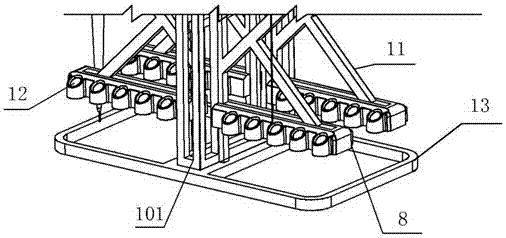

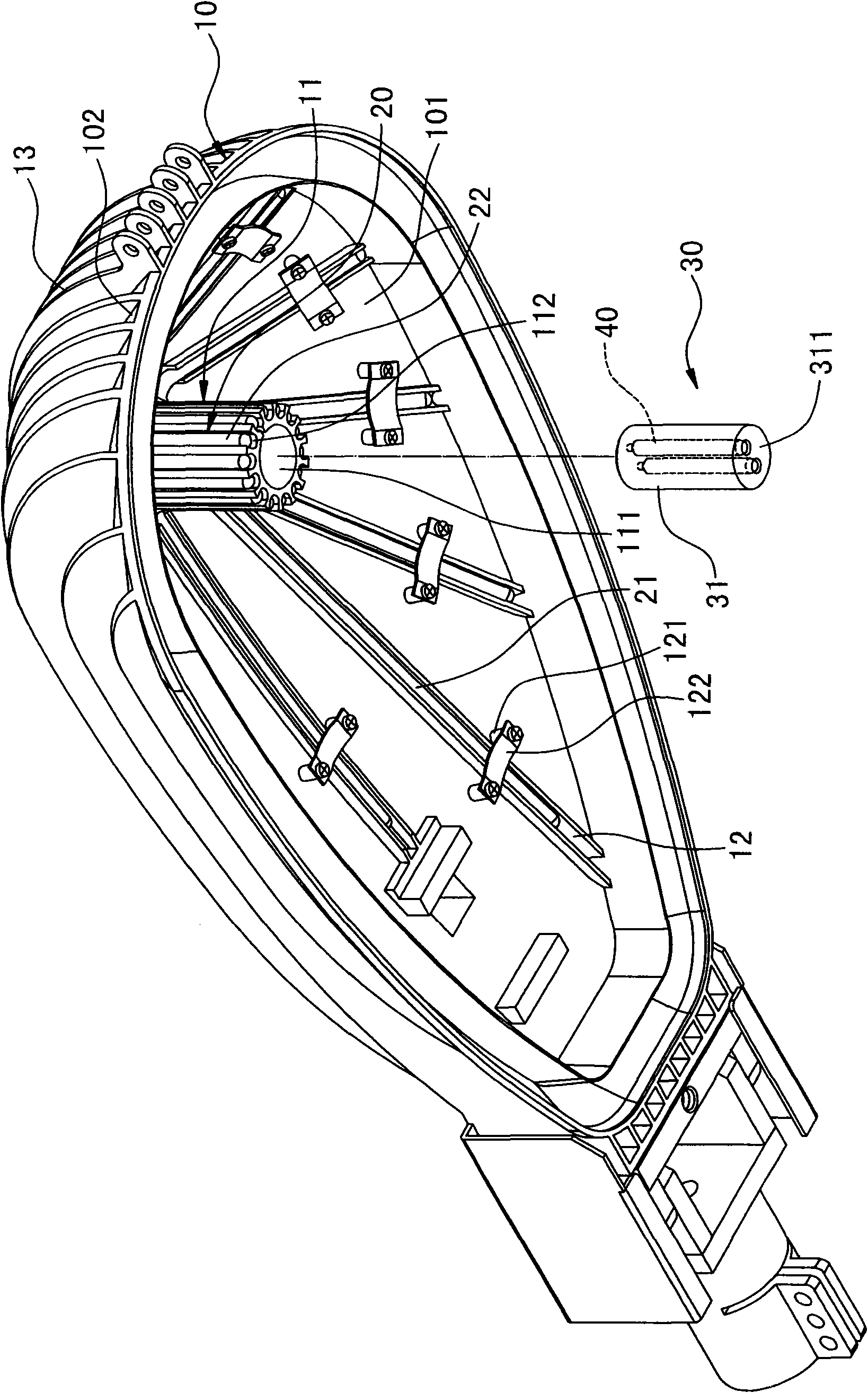

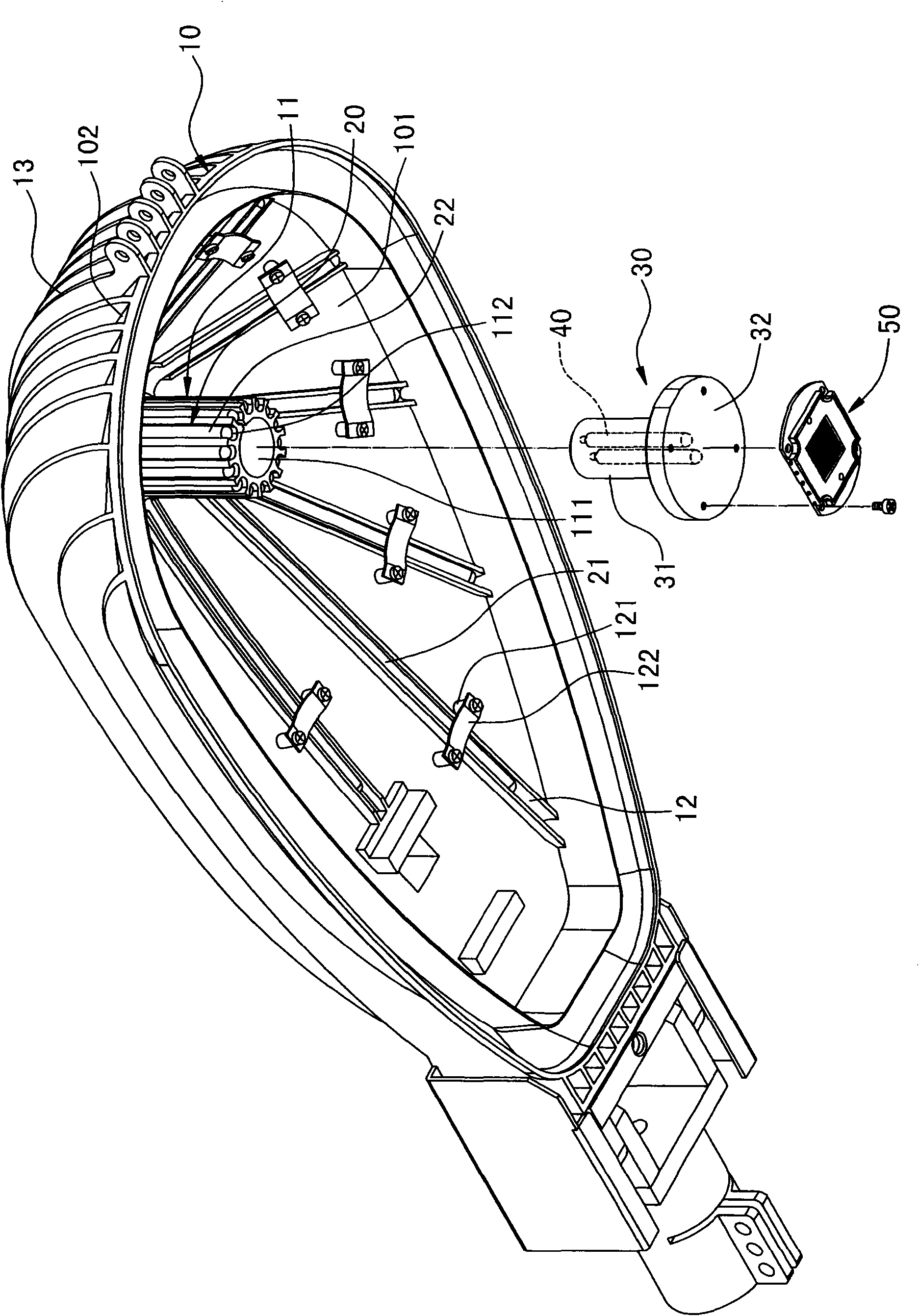

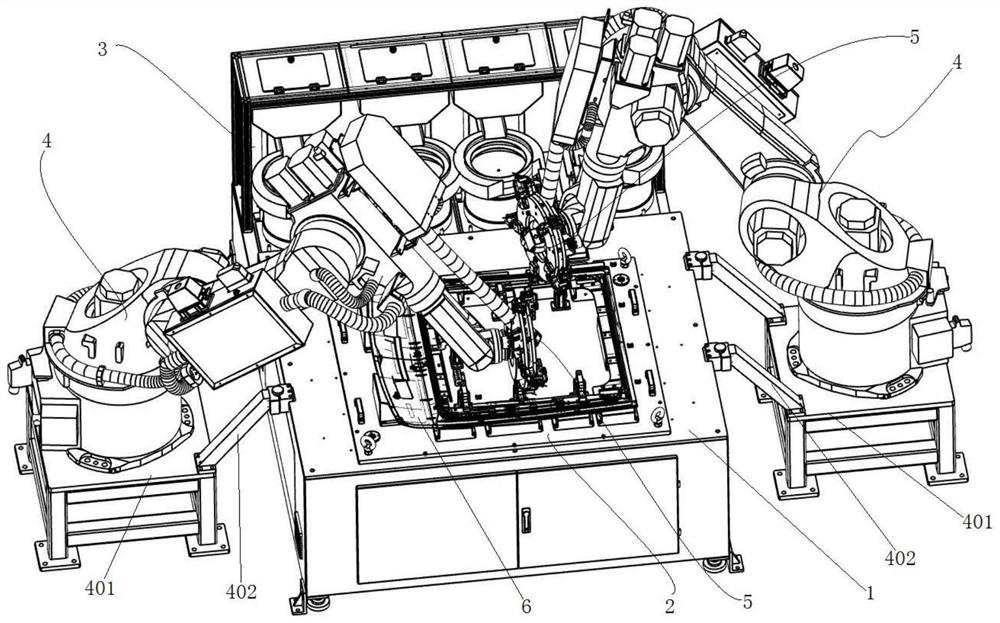

Beam down system solar generation device

InactiveCN101903653AIncrease the number of settingsEfficient power generationSolar heating energyMirrorsShadowingsHeliostat

This object aims to provide a center reflector support device configured to improve setting density of heliostats, to reduce the blocking or shadowing of reflection light from the heliostats, and to stably and firmly support a central reflector. In a beam down system solar generation device, the center reflector is fixed on one side of a standing post in a cantilever fashion, a pylon is stood at the top of the post, the center reflector is fixed by a stay member set at the pylon, and the post is supported by a stay member to connect the pylon and a jut jutting out into the back side of the post with a base.

Owner:MITSUI ENG & SHIPBUILD CO LTD

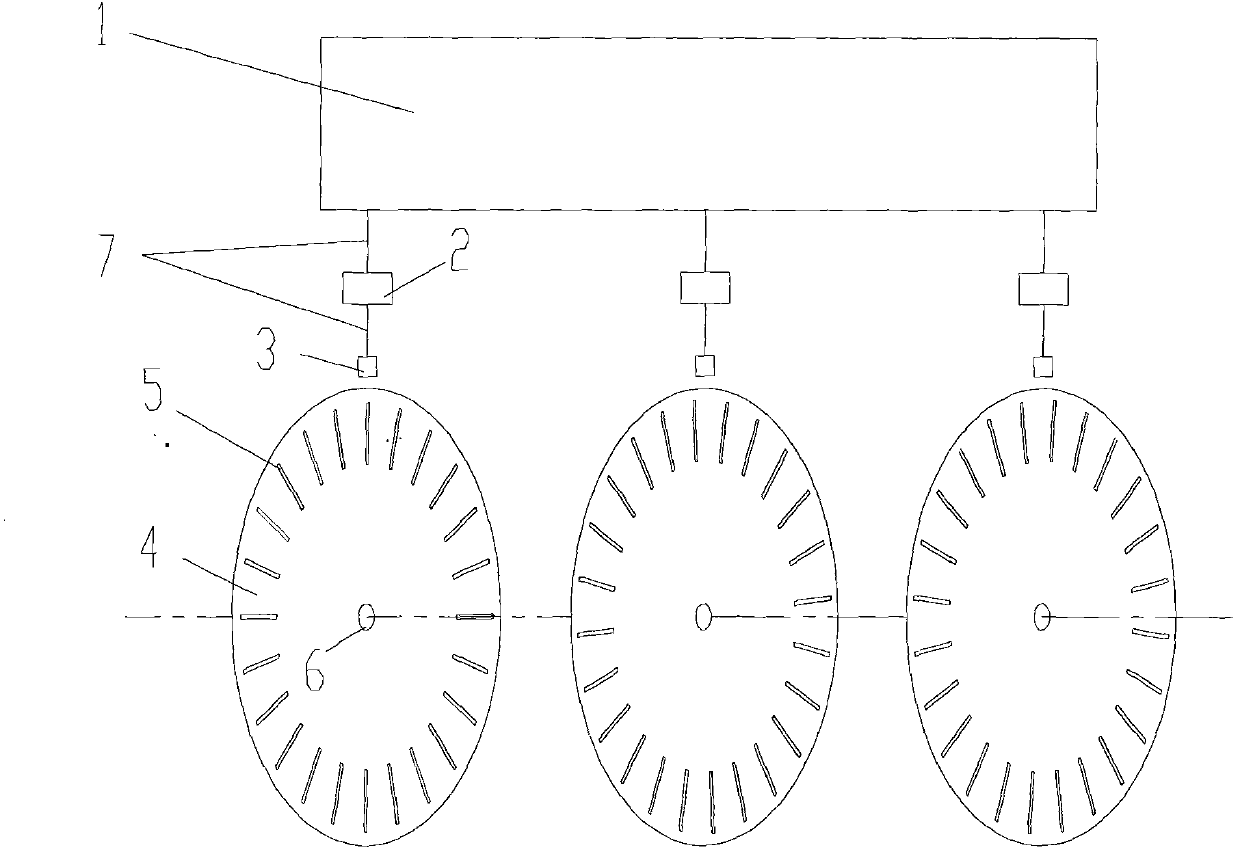

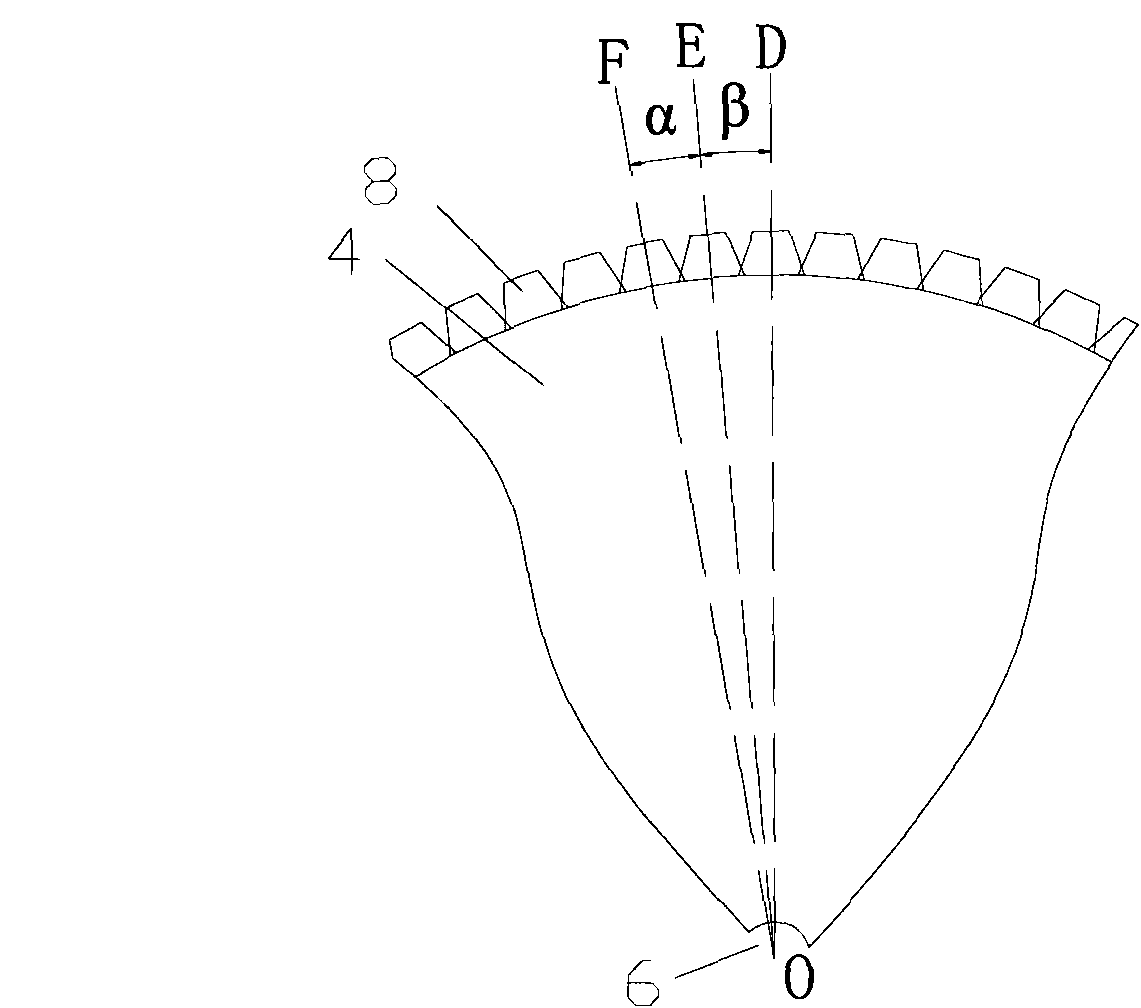

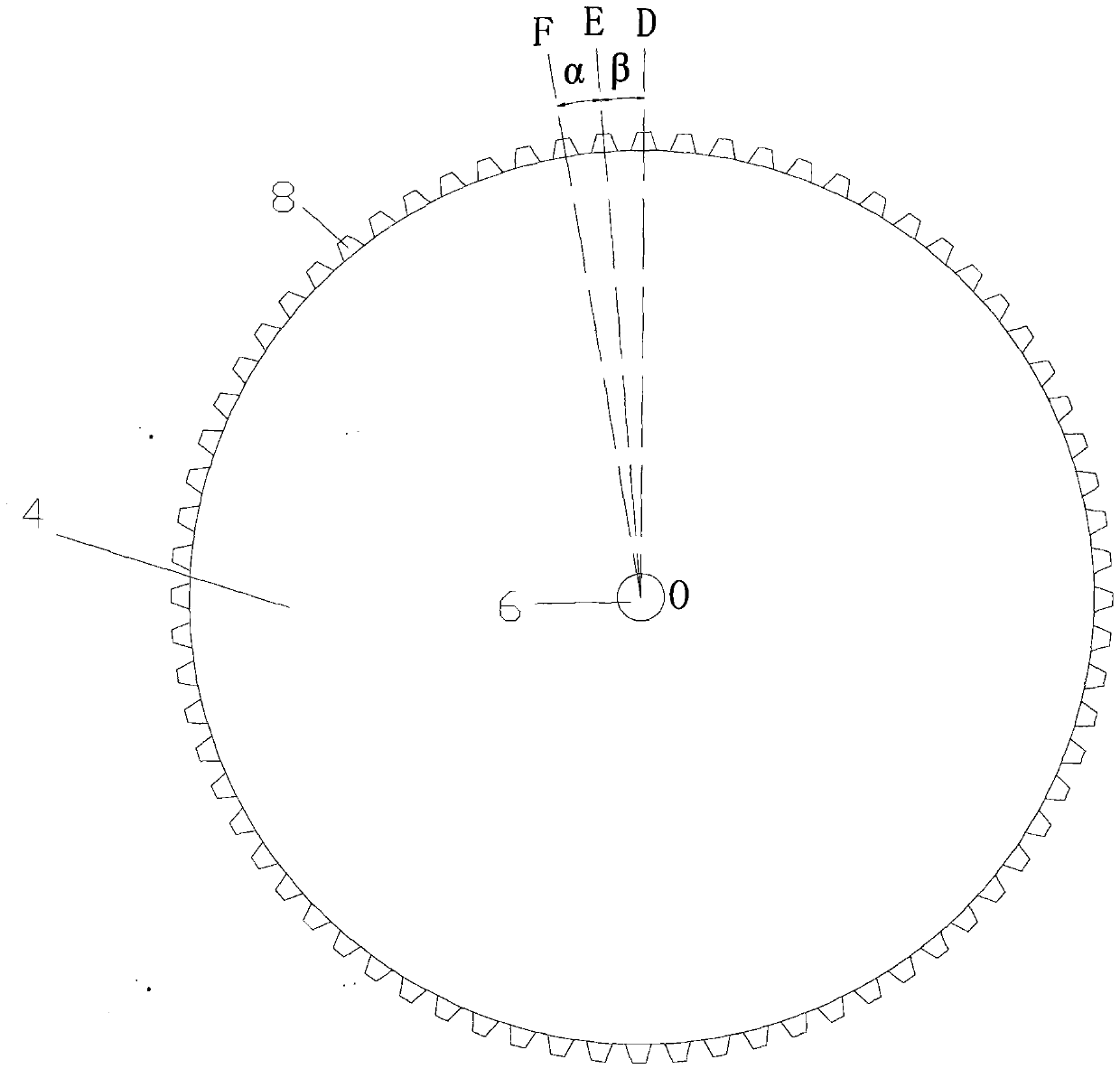

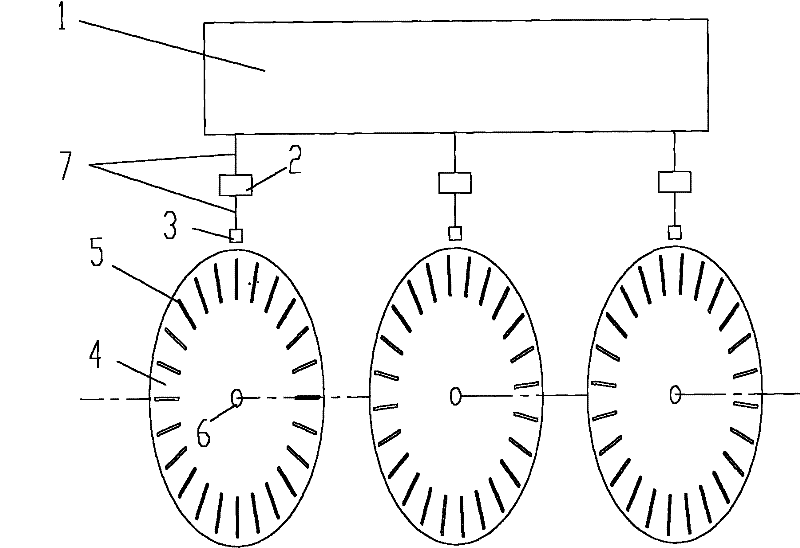

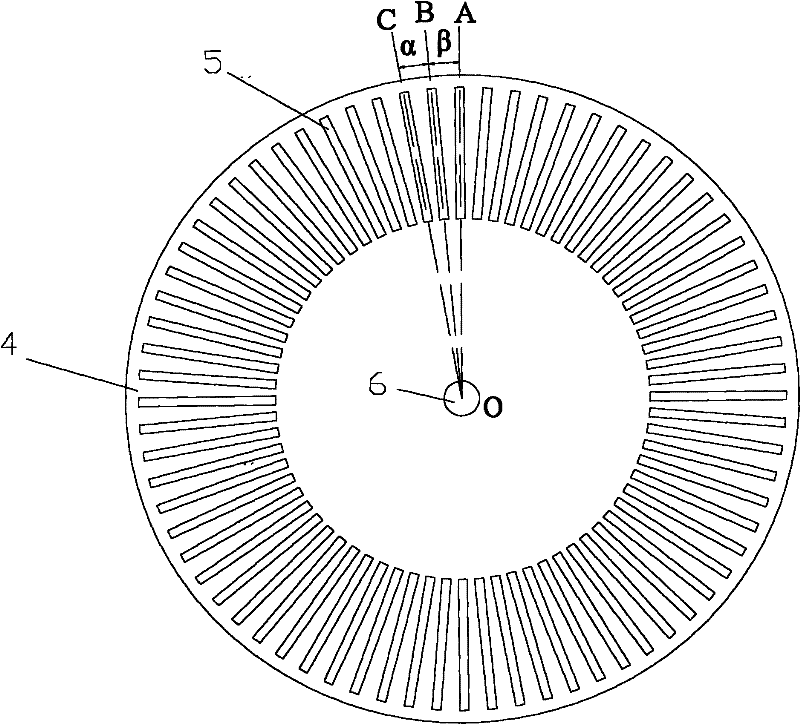

High-resolution rotation-speed measuring device

InactiveCN101907633AImprove measurement resolutionProcessing speedLinear/angular speed measurementPhysicsHigh resolution

The invention discloses a high-resolution rotation-speed measuring device. In each rotation-speed collecting unit, rectangular light-transmitting holes are evenly distributed on the end surface of a rotating disk along a circumferential direction, the rectangular light transmitting holes pass through a circle center of the rotating disk along a center line of a length direction, a sensing device approaches to the rectangular light transmitting holes of the rotating disk, the output end of the sensing device is connected with the input end of a signal conditioning device through a signal wire, the signal conditioning device is used for converting signals output by the sensing device into square signals, the output end of the signal conditioning device is connected with a computer through the signal wire; the end surfaces of the rotating disks in each rotation-speed collecting unit are mutually parallel, and a connecting wire of the circle centers of the rotating disks is a straight line and is perpendicular to the end surface of each rotating disk; on a projection plane which is perpendicular to the connection wire, an included angle is formed between the center line of the rectangular light-transmitting holes of the rotating disks along the length direction and an orthogonal projection on the projection plane, and the included angles of the adjacent orthogonal projections of the center line are equal and are greater than zero. The invention can ensure that the measurement resolution is increased exponentially.

Owner:ZHEJIANG UNIV

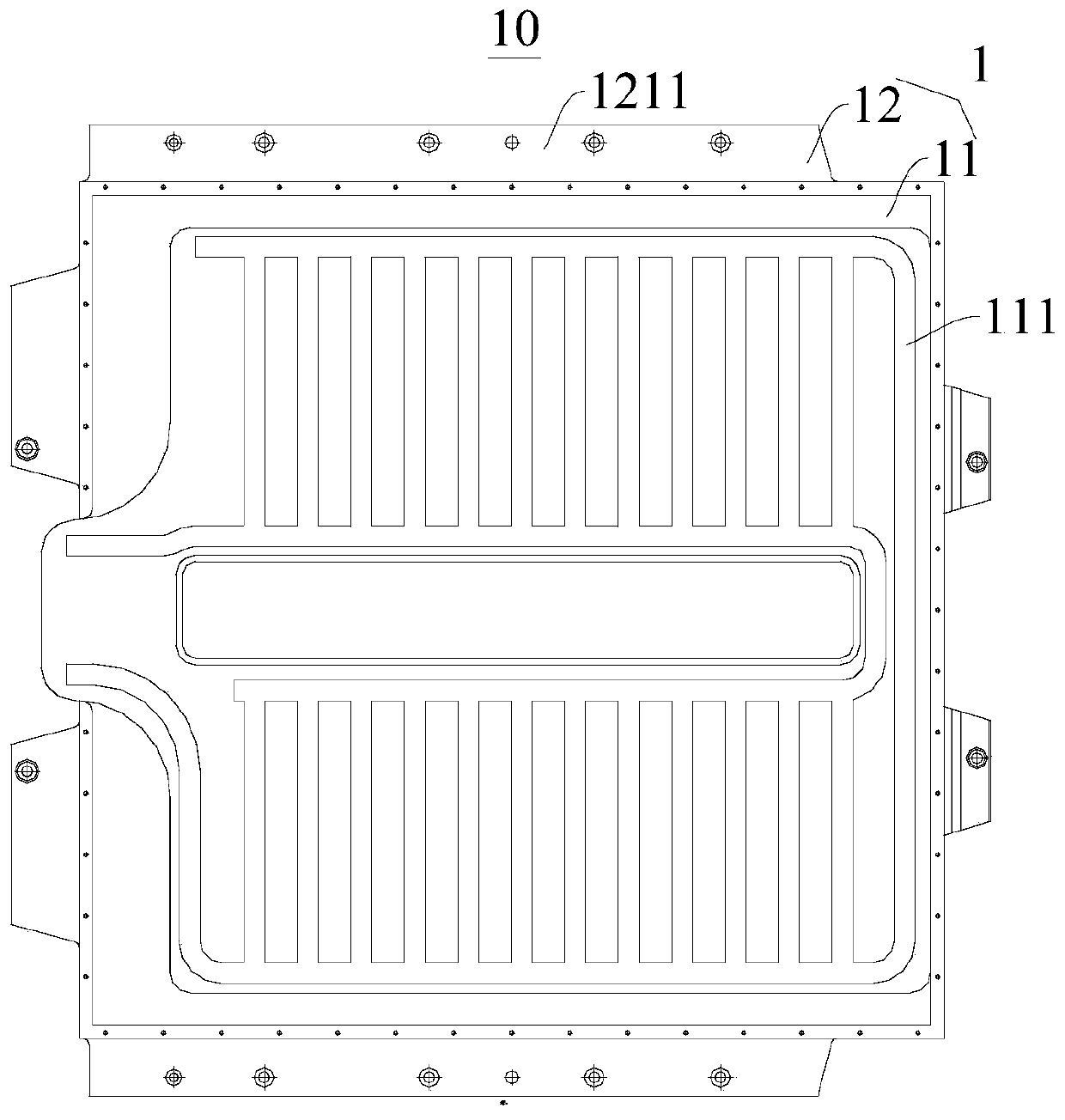

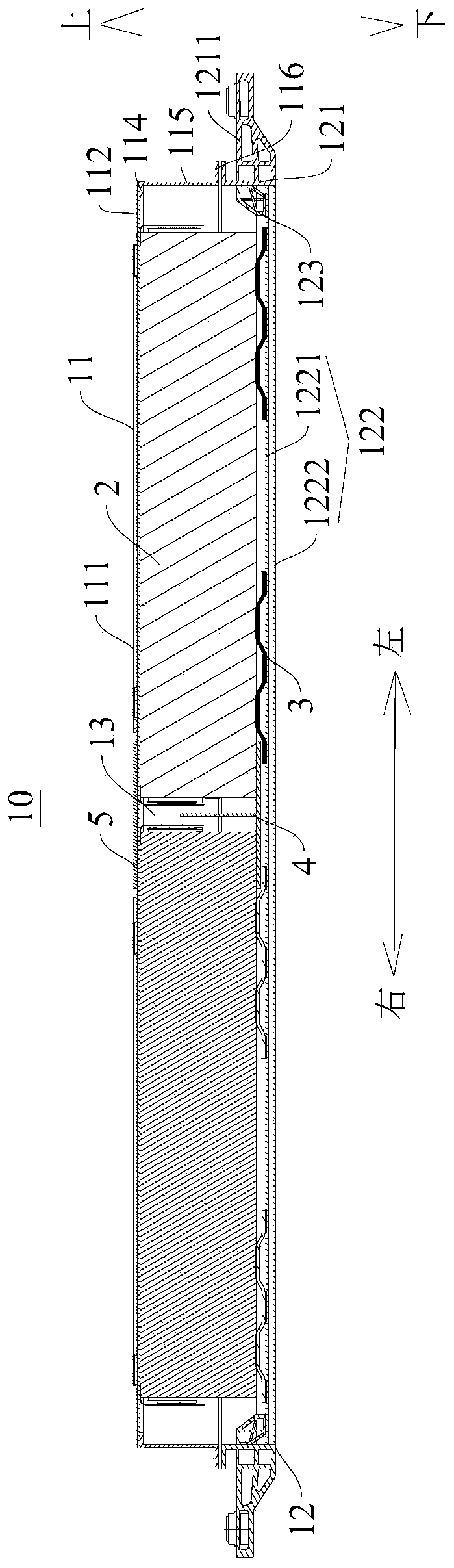

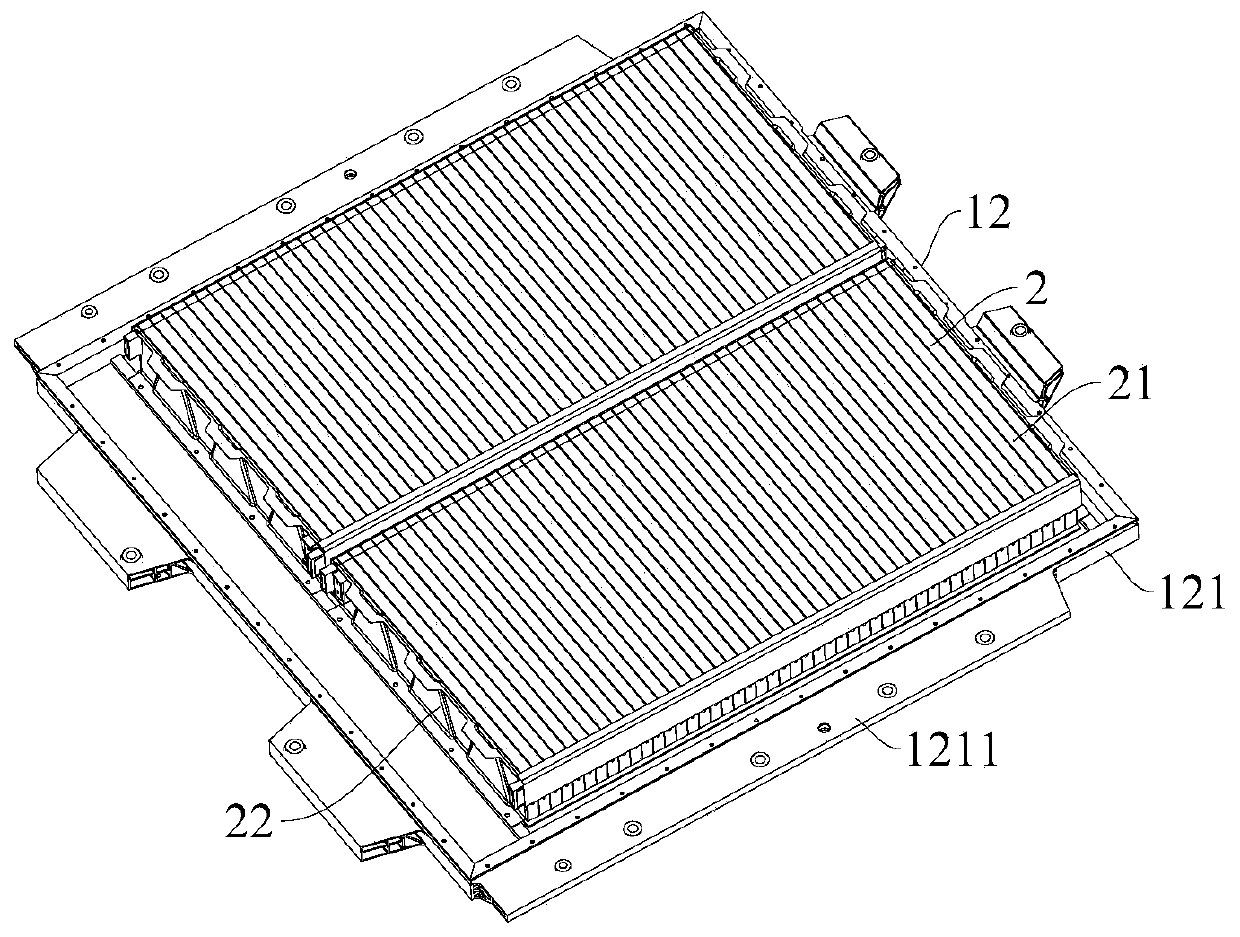

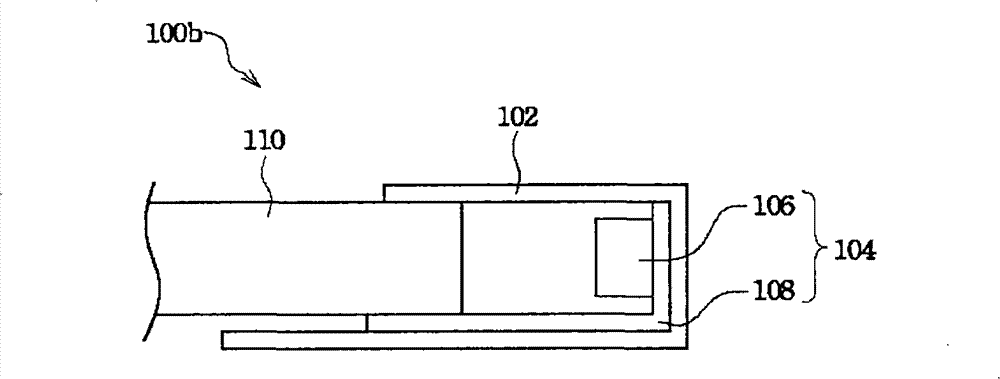

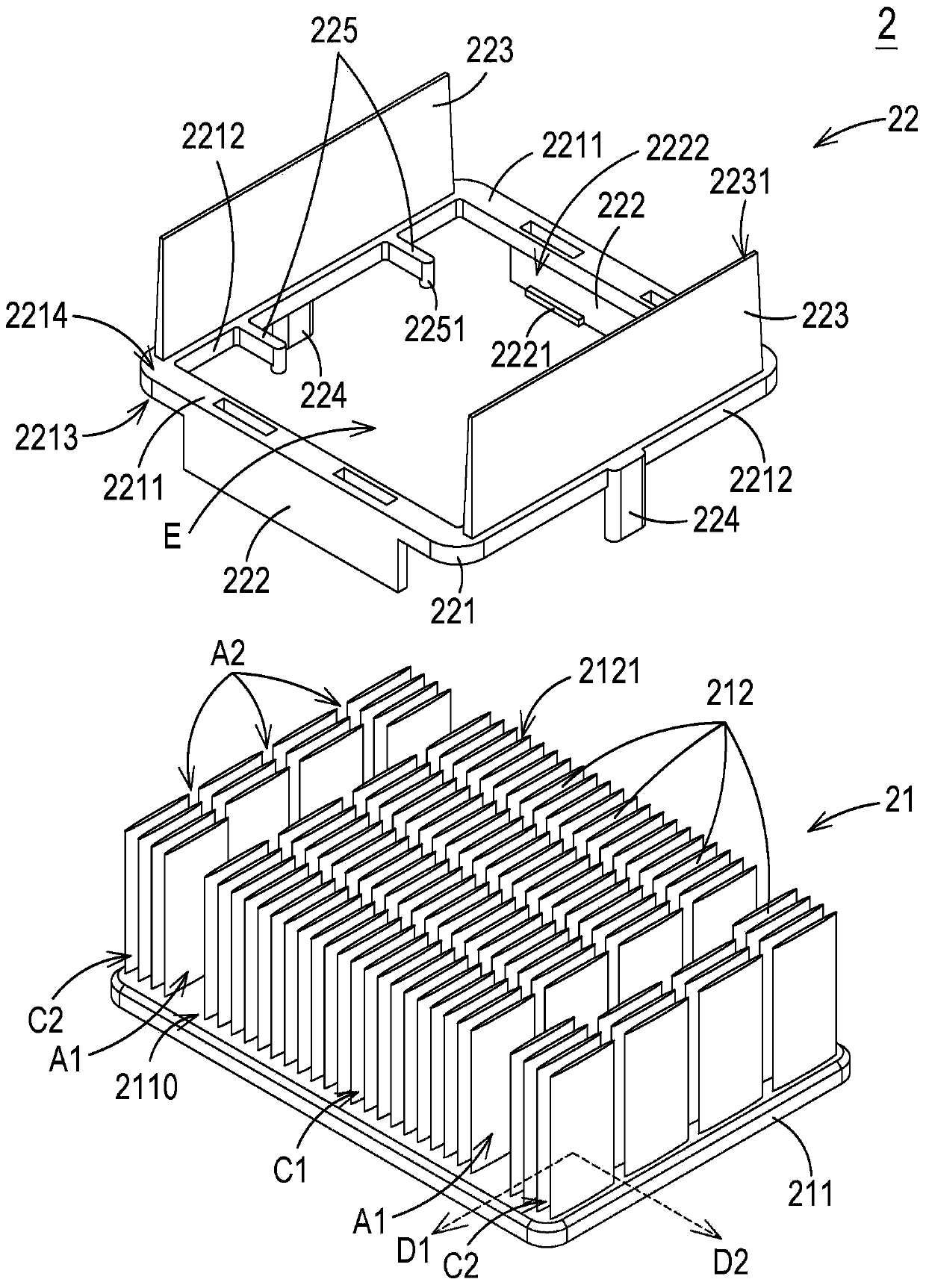

Battery pack

ActiveCN111430611AIncrease the number of settingsImprove battery lifeCell component detailsStructural engineeringMechanical engineering

A battery pack provided by the present invention comprises a shell which comprises an upper shell and a lower shell, wherein the upper shell and the lower shell define an accommodating cavity; a plurality of battery cells which are arranged in the accommodating cavity and form a plurality of rows of battery cell assemblies, wherein the plurality of rows of battery cell assemblies are parallel, andthe plurality of battery cells in each row of battery cell assemblies are sequentially stacked along the length direction of the shell; a supporting structure which is supported between the lower shell and the plurality of battery cells, and is connected with the lower shell and the plurality of battery cells so as to fix the plurality of battery cells to the lower shell. Therefore, the pluralityof battery cells are stacked into the plurality of rows of battery cell assemblies, in the process of producing the battery pack, the plurality of battery cells do not need to be arranged into a battery module firstly, and the number of the battery cells arranged in the battery pack can be increased, so that the cruising ability of the battery pack can be improved. In addition, the plurality of battery cells can be reliably fixed on the lower shell through the arrangement of the supporting structure, and the battery cells can be prevented from loosening.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

Smart umbrella stand for receiving sharing umbrella

InactiveCN107450399ACompact structureConvenient travelProgramme controlComputer controlActuatorEmbedded system

The invention discloses an intelligent umbrella stand for accommodating shared umbrellas, which includes an umbrella stand for placing umbrellas and a controller for controlling the umbrella stand to lock the umbrellas. The umbrella stand is provided with at least one To lock the umbrella handle of the sunny umbrella and the lock machine connected to the controller, each lock machine on the umbrella frame is provided with a micro switch connected to the controller; the controller is also connected to a communication module. The present invention has a simple and compact structure, and is the executive mechanism of the entire shared umbrella system. By arranging the devices of the present invention in a certain area, and then connecting each device with a remote main server to form a shared umbrella management leasing system, it can be used in a certain area. The rental service of shared umbrellas is provided in the area to facilitate people's travel.

Owner:成都源来来科技有限公司

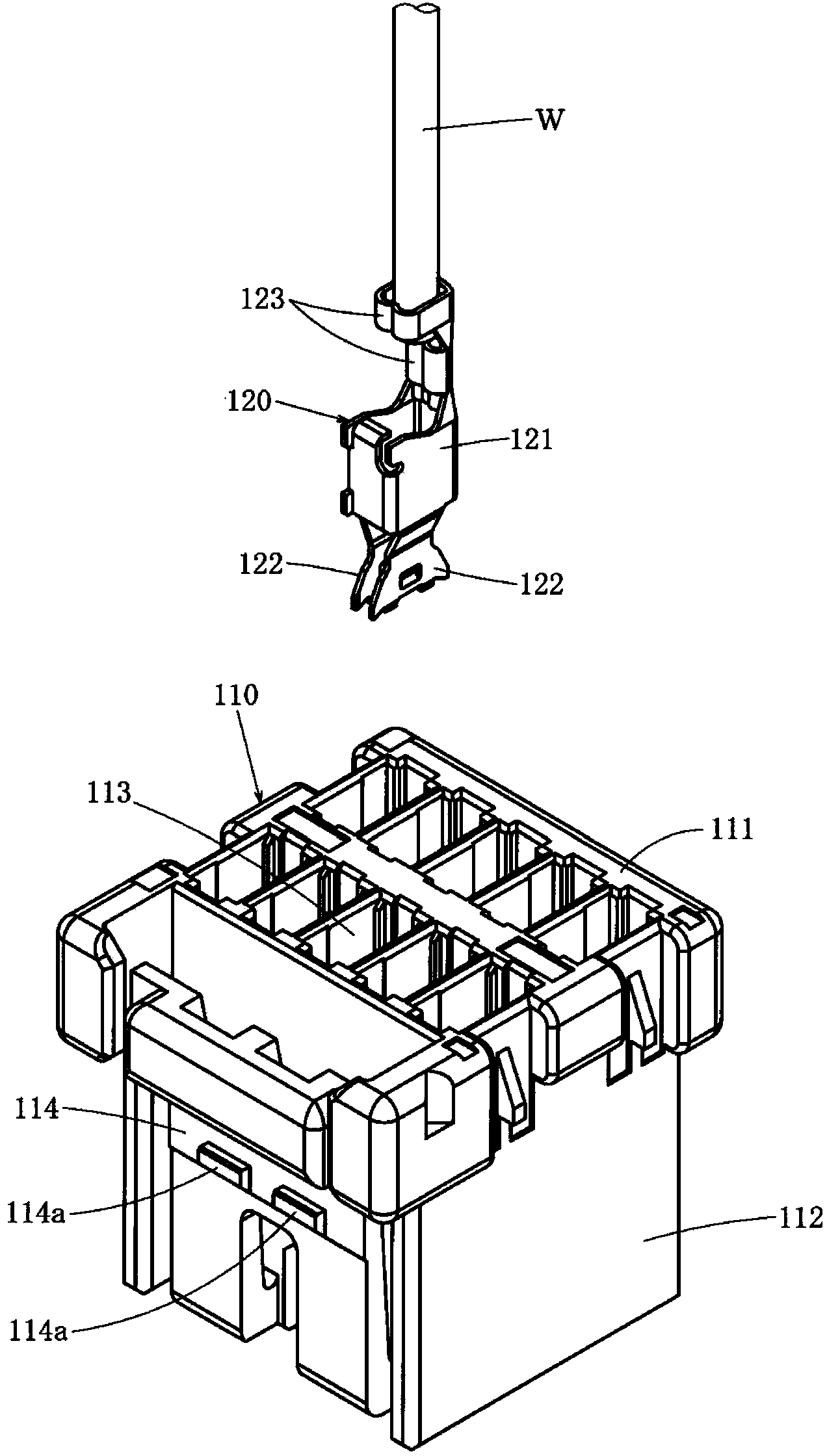

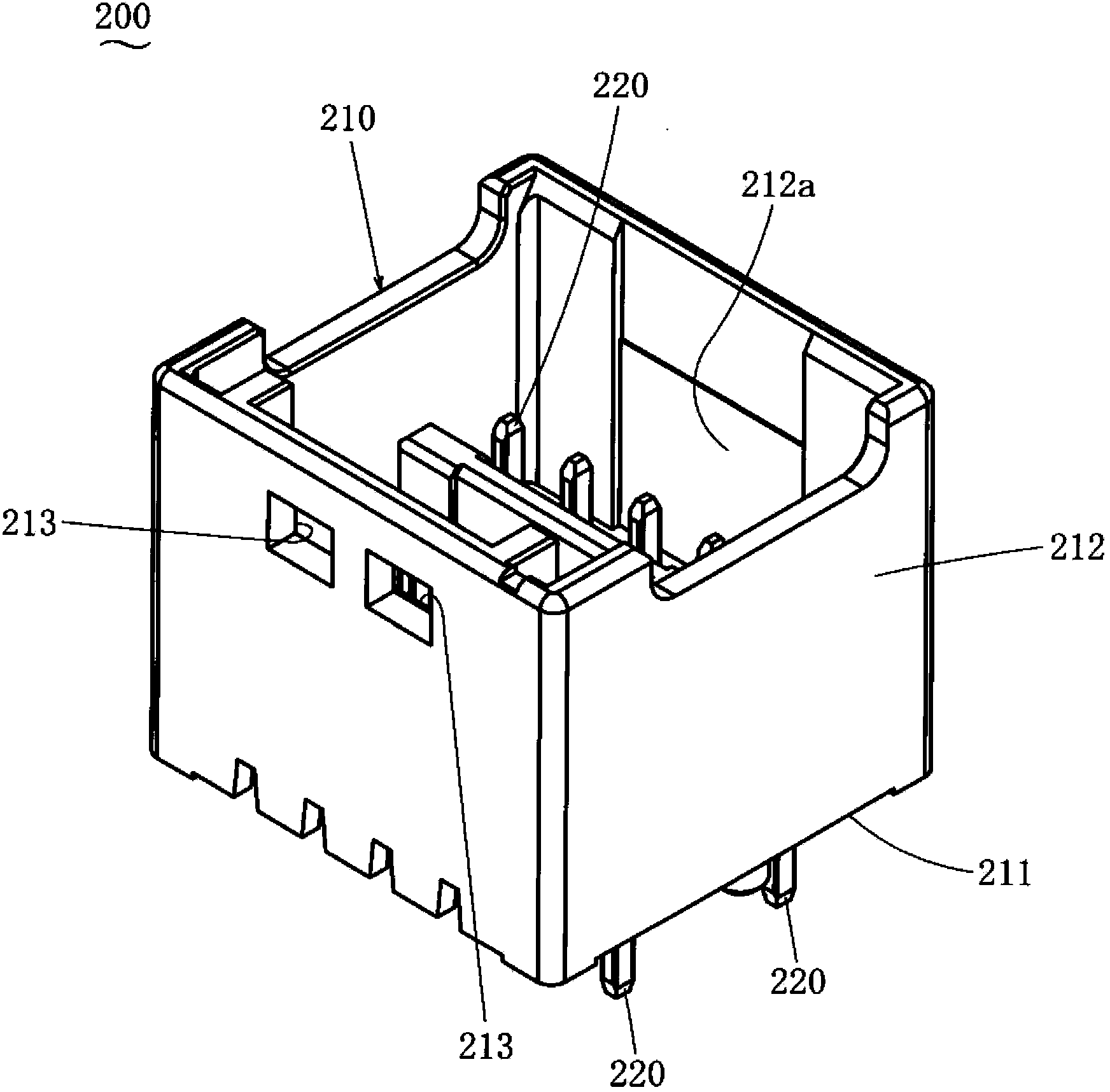

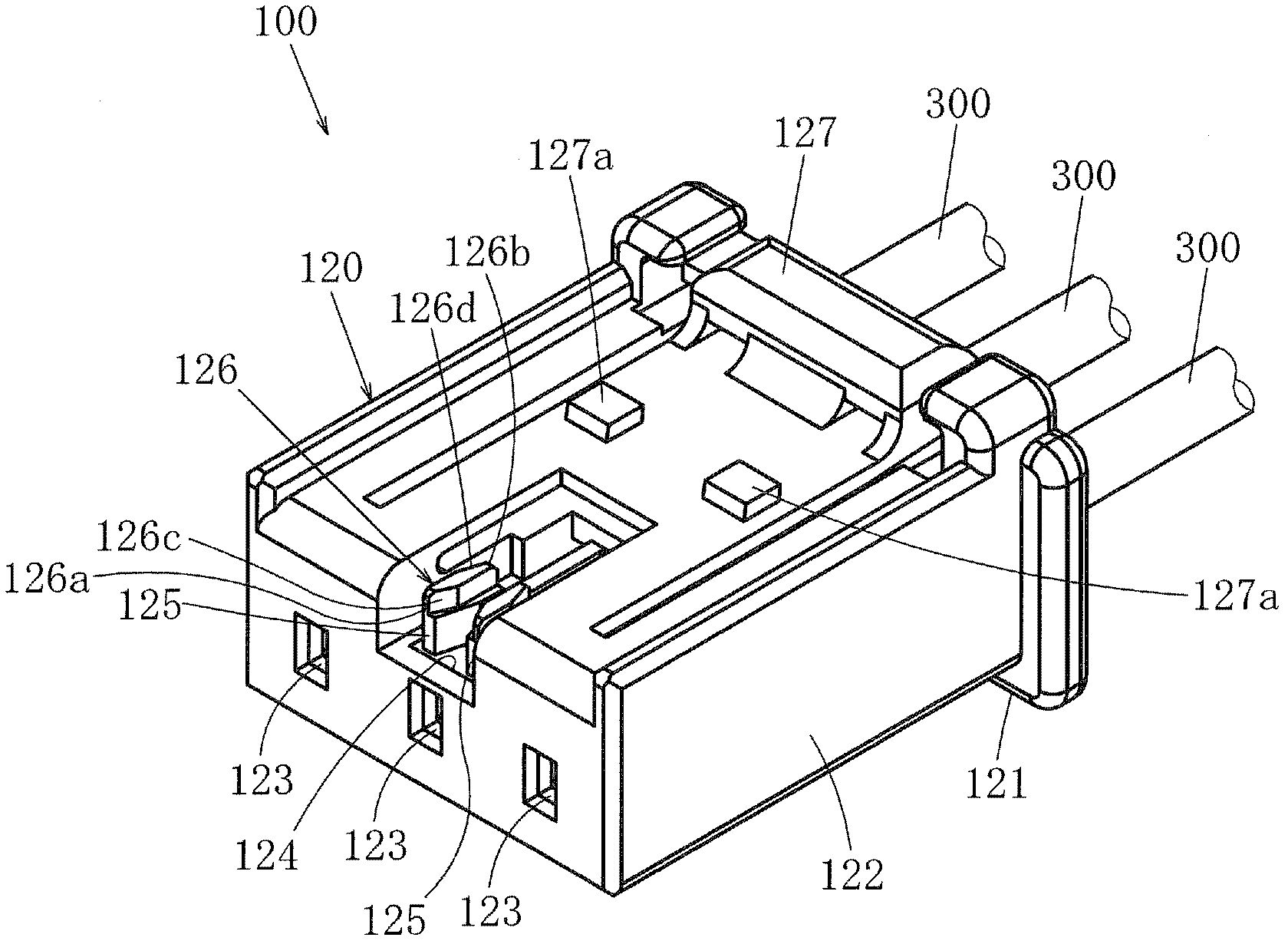

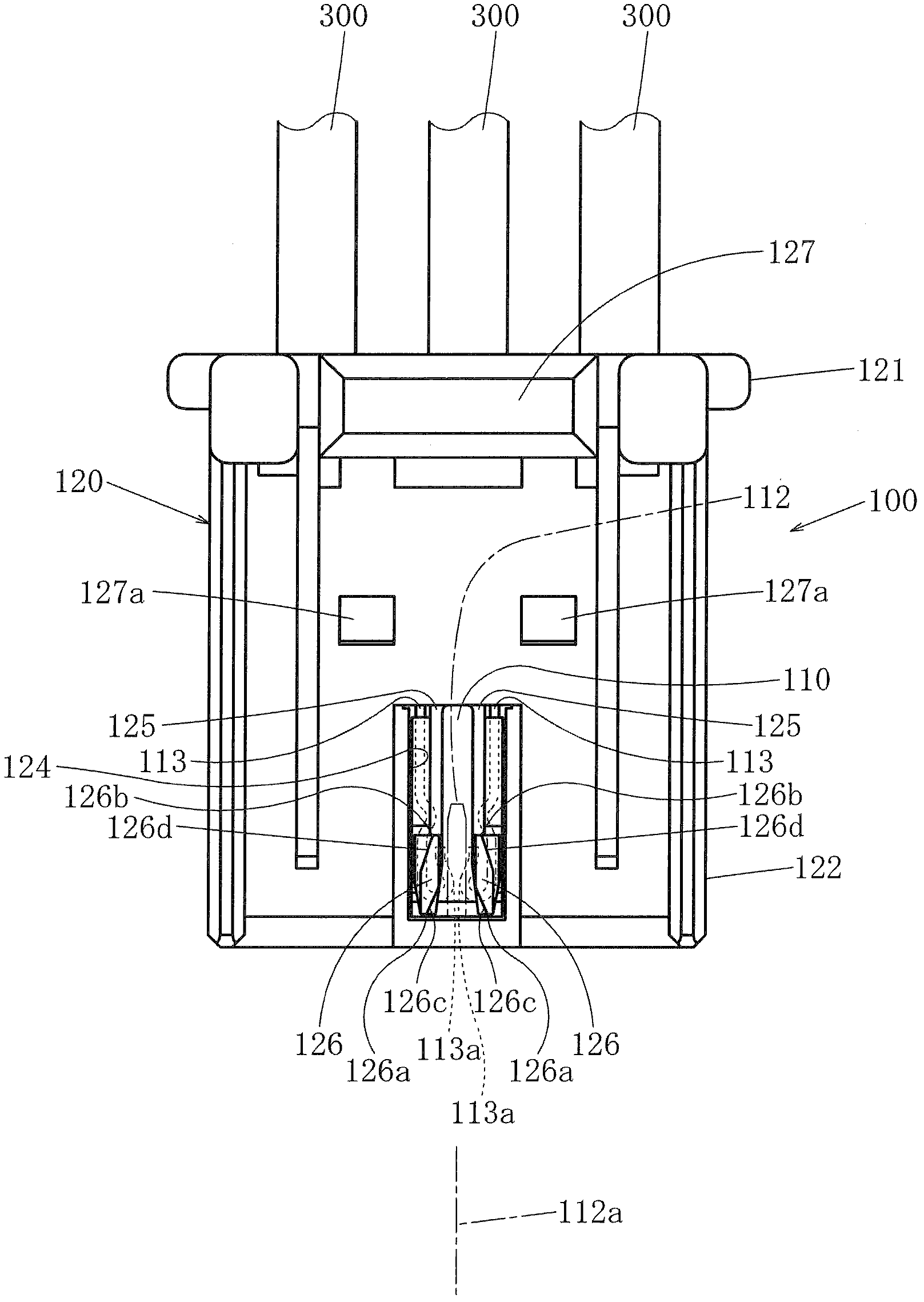

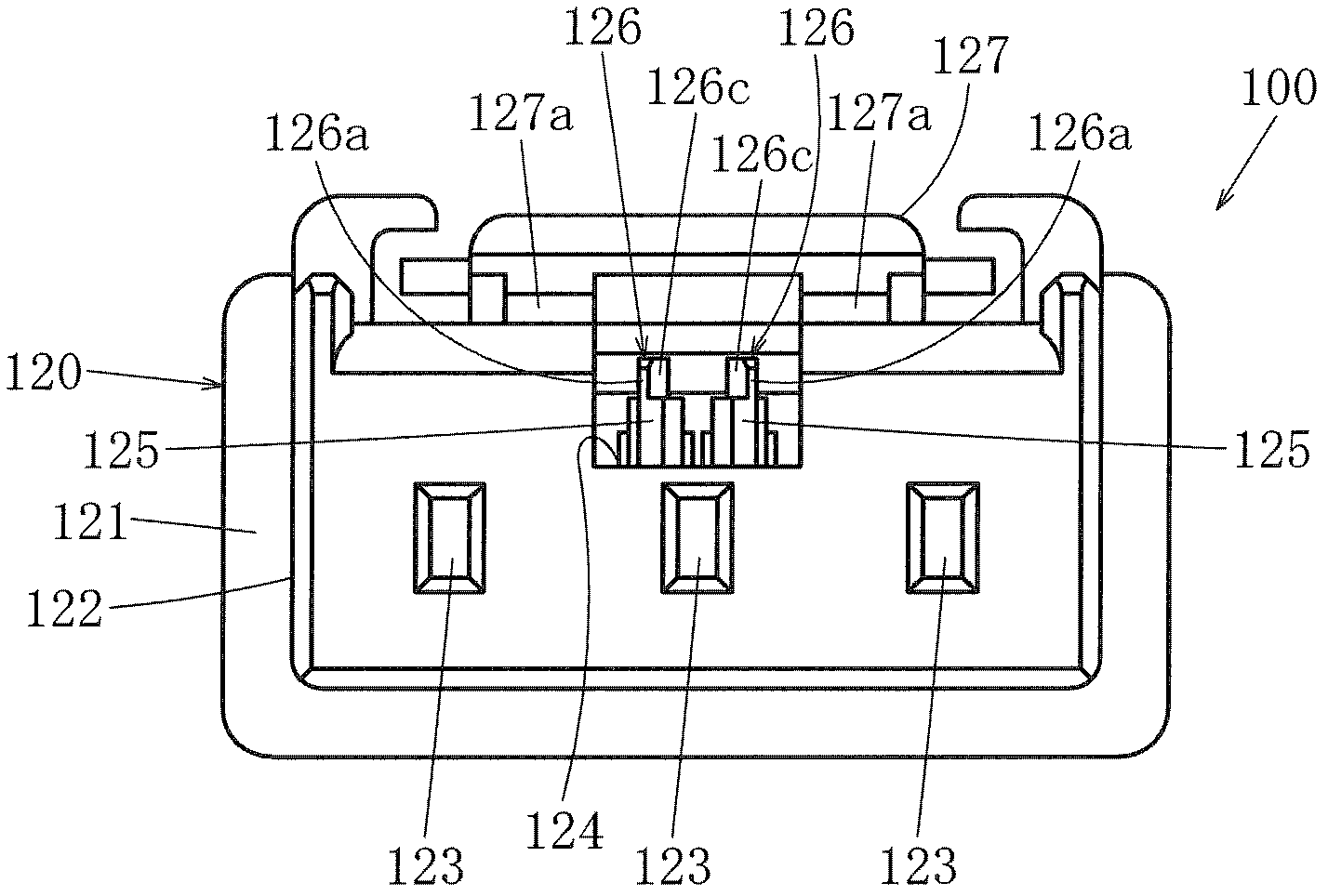

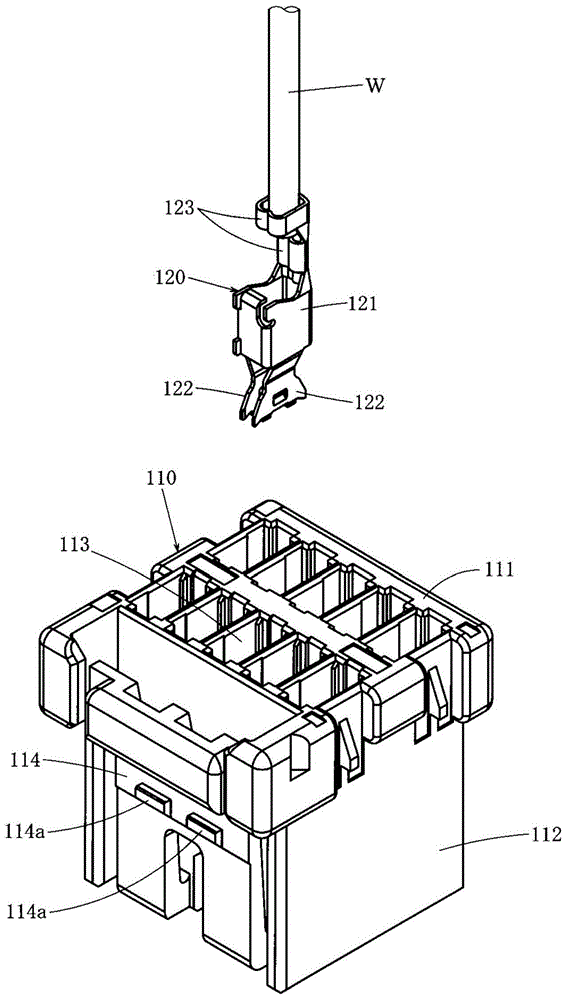

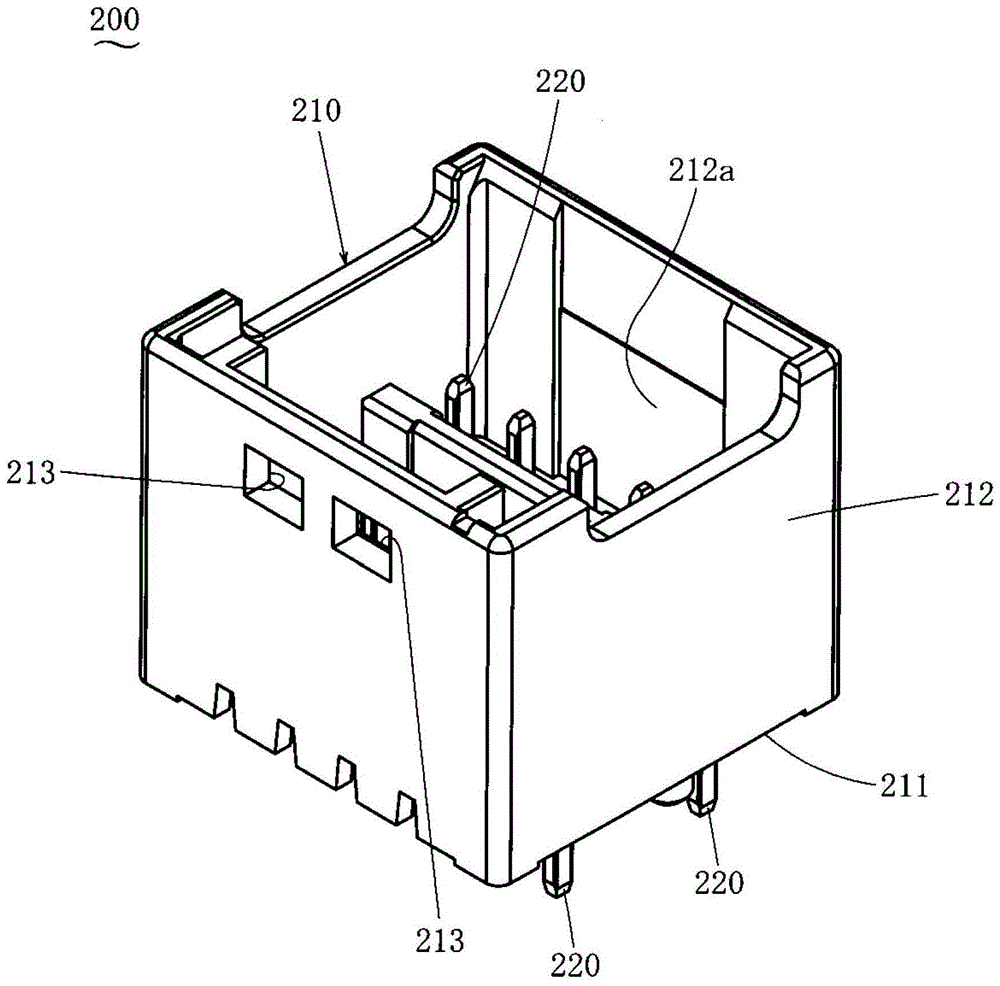

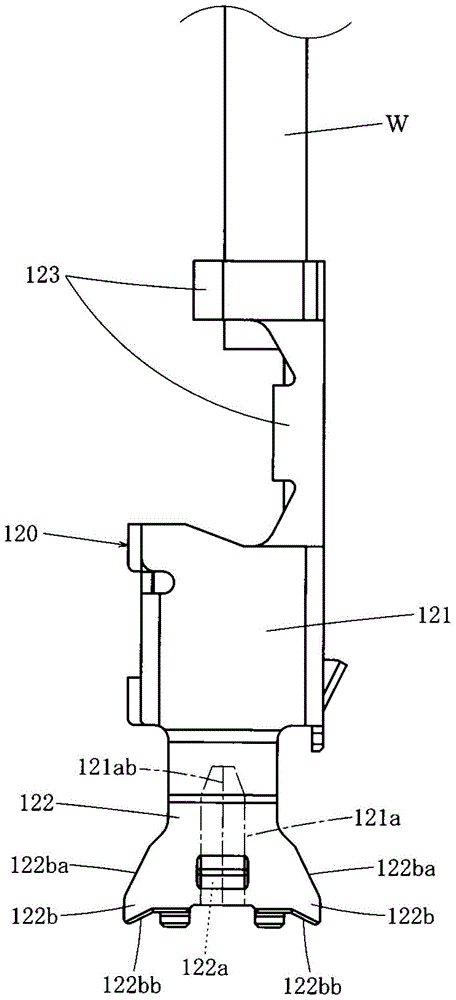

Electric connector with detection unit

ActiveCN103457106AIncrease the number of settingsIncrease freedomIncorrect coupling preventionEngineeringMechanical engineering

Owner:JST MFG CO LTD

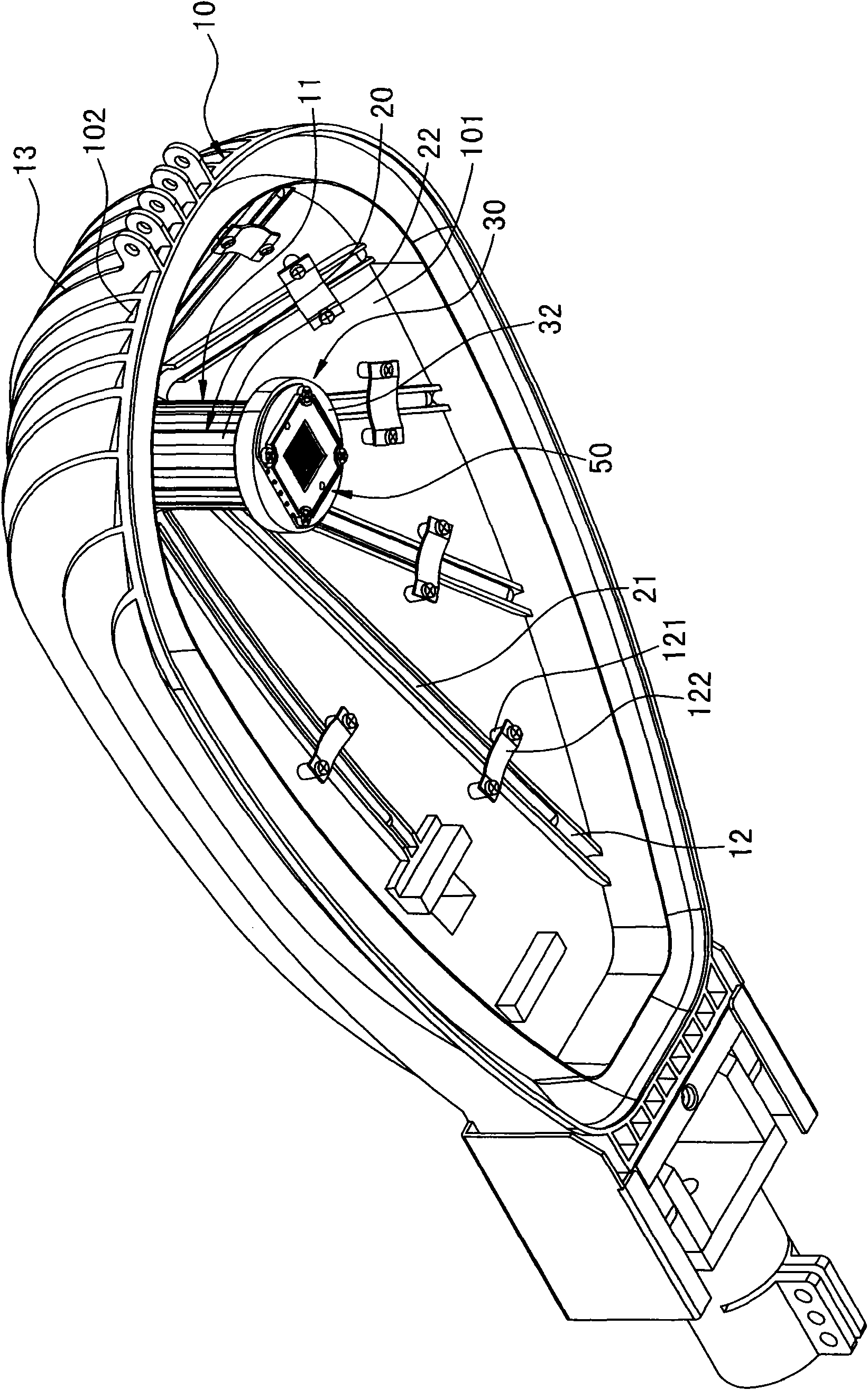

LED lamp and heat dissipating structure thereof

InactiveCN101666478ARapid drainageEvenly dispersePoint-like light sourceSemiconductor/solid-state device detailsHeat conductingHeat resistance

The invention discloses an LED lamp and a heat dissipating structure thereof. The heat dissipating structure comprises a first heat conducting column extended along the inner bottom surface of a cavity of the heat dissipating structure, and a lampshade provided with a plurality of grooves; a peripheral ring of the first heat conducting column is provided with a plurality of accommodating holes andcombined with an evaporation end of a first heat pipe, and a condensation end of the first heat pipe is jointed with the groove of the lampshade; moreover, the heat dissipating structure comprises aheat conducting module provided with a second heat conducting column and a heat conducting plate, and the heat conducting module is mutually sleeved with the first heat conducting column by the secondheat conducting column to joint an LED luminous module to the heat conducting plate to form the LED lamp with the heat dissipating structure so as to remove the heat generated by the LED luminous module. By adopting the LED lamp provided by the invention, a radiating fin does not need to be additionally machined and the heat pipe is not needed to be inserted, so the manufacturing and machining cost for the radiating fin can be reduced, and the heat resistance can be reduced at the same time; and the first heat conducting column and the second heat conducting column are mutually sleeved to increase the elasticity and practicability on the structural design.

Owner:白豪

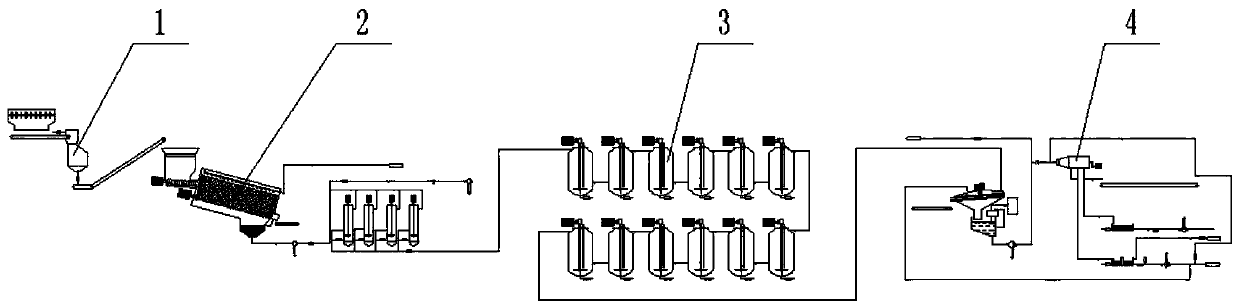

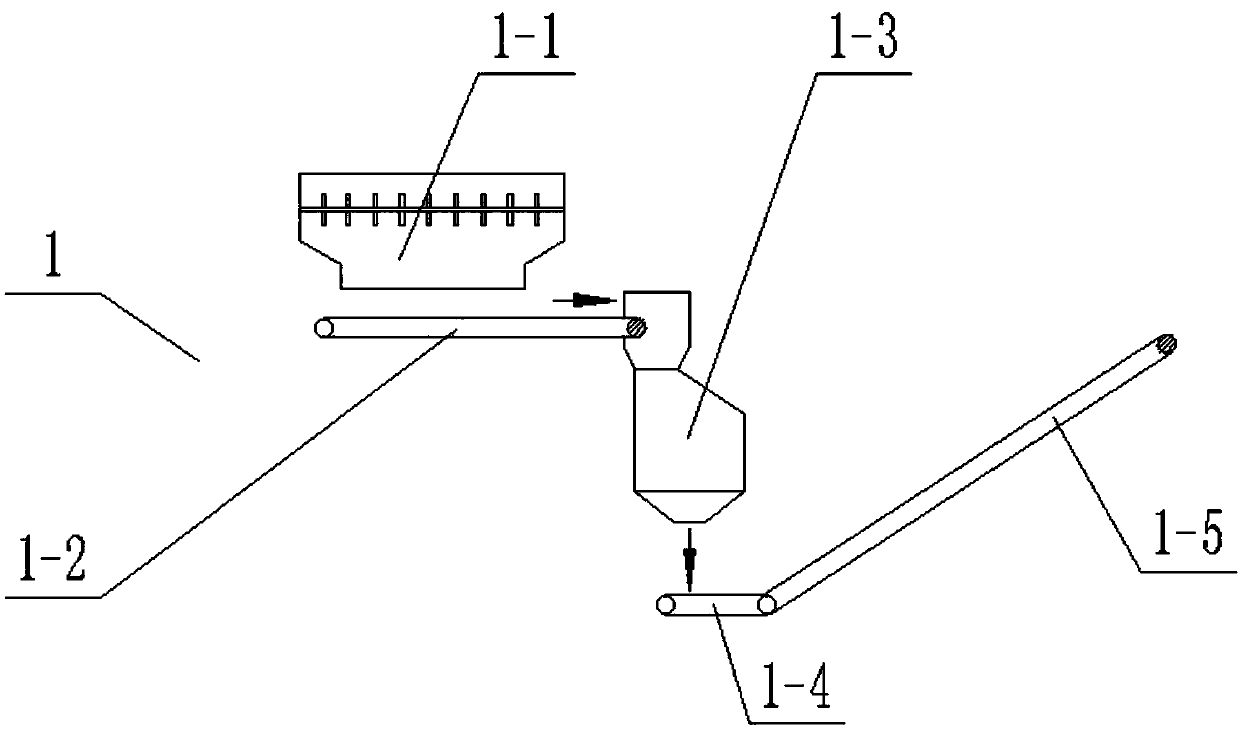

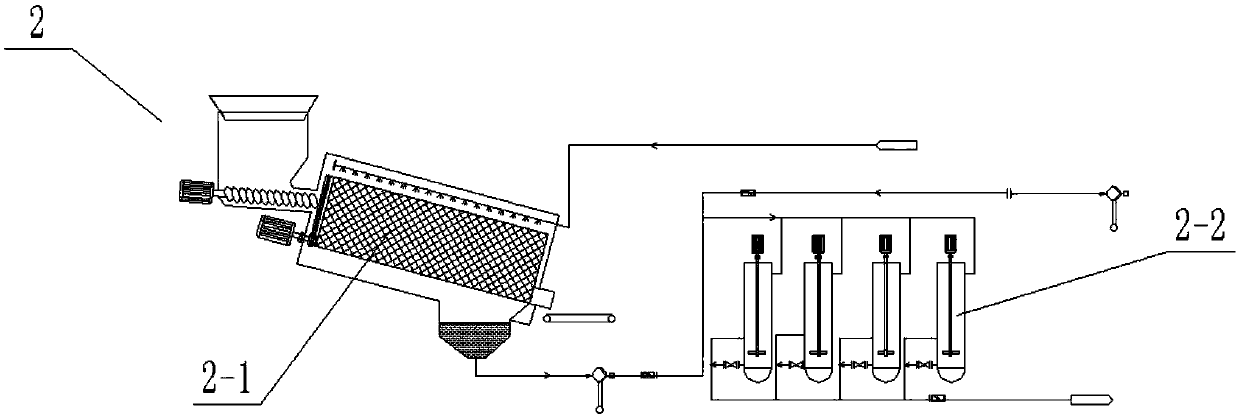

Intensive oily sludge processing prying tool

ActiveCN107640878AImprove processing efficiencyEasy to handleSludge treatment by de-watering/drying/thickeningByproduct vaporizationSludgeSmall footprint

The invention relates to the field of oily sludge processing, in particular to an intensive oily sludge processing prying tool. The intensive oily sludge processing prying tool comprises a front oilysludge preprocessing device, a rear oily sludge preprocessing device, an intensive processing device and an oily sludge and water sludge separation device, wherein the front oily sludge preprocessingdevice and the rear oily sludge preprocessing device are connected; the rear oily sludge preprocessing device is connected with the intensive processing device; the intensive processing device is connected with the oily sludge and water sludge separation device. According to the intensive oily sludge processing prying tool, various physical effects and functions are used for processing the oily sludge, no chemical agents need to be added to realize the processing of the oily sludge, and no secondary environment pollution is generated. The intensive oily sludge processing prying tool has the advantages of large equipment handling capacity, high efficiency, good effect and low cost. Since a prying structure is adopted, land occupation is small. During a short-time operation, the intensive oily sludge processing prying tool is put on the right side of a platform trailer to be used, and is put on the ground to be fixedly used during a long-time operation so as to be agile and mobile.

Owner:HEILONGJIANG LANDE ULTRASONIC TECH CO LTD

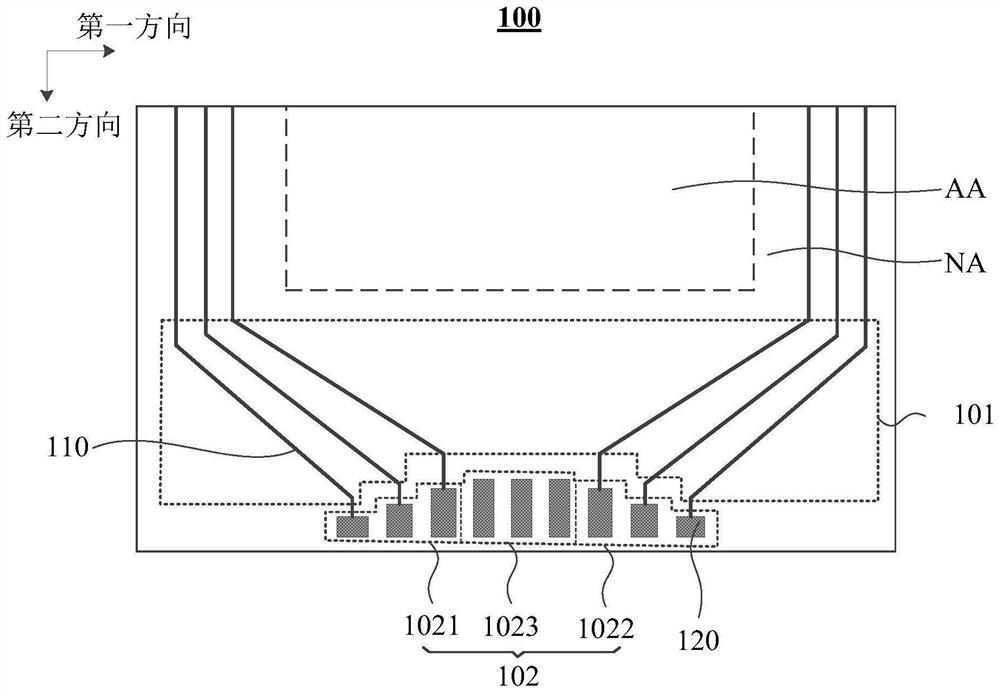

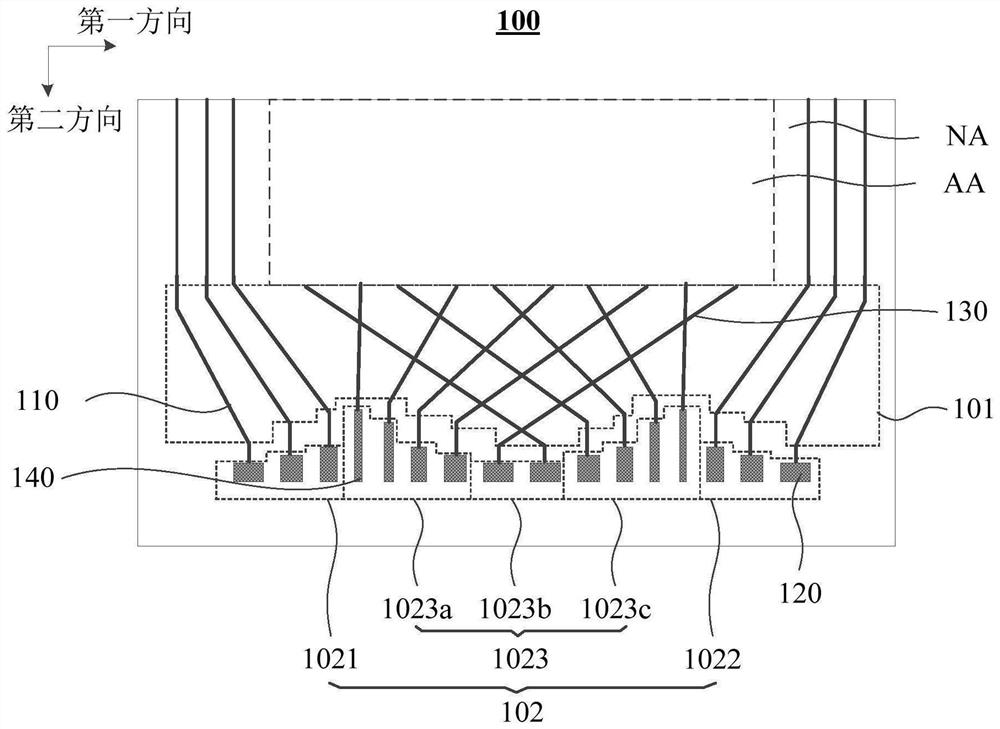

Array substrate, display panel and display device

ActiveCN112133201AAchieve narrow bezel designIncrease the number of settingsIdentification meansDisplay deviceElectrical connection

The invention discloses an array substrate, a display panel and a display device. The array substrate comprises a display area and a non-display area surrounding the display area, wherein the non-display area comprises a fan-out area and a binding area; the fan-out area is located between the binding area and the display area; the fan-out area is provided with a plurality of first connecting lines; the binding area is provided with a plurality of first binding terminals; the first connecting wires are electrically connected with the first binding terminals in a one-to-one correspondence manner; the first binding terminals are arranged along a first direction; in the first direction, the binding area comprises a first area and / or a second area and a third area, and the first area and the second area are located on the two opposite sides of the third area; the plurality of first binding terminals are located in the first area and / or the second area; in the first direction, the lengths ofthe plurality of first binding terminals in the binding area are gradually reduced from the center to the two sides, and the widths of the plurality of first binding terminals are gradually increasedfrom the center to the two sides. The embodiment of the invention is beneficial to realizing a narrow frame design.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

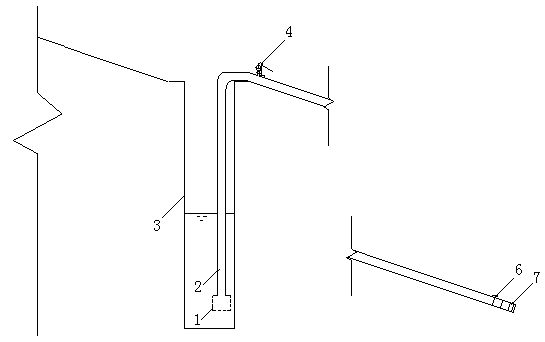

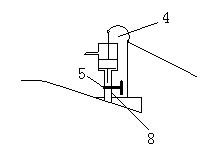

Water-filling type siphon drainage device applicable to radioactive well

InactiveCN103741703AEasy to measureIncrease the number of settingsFoundation engineeringSiphonEngineering

The invention discloses a water-filling type siphon drainage device applicable to a radioactive well. The water-filling type siphon drainage device comprises a siphon pipe and a water pumping well, wherein a filter screen shield is arranged at a water inlet end of the siphon pipe; an opening is formed in a top of the siphon pipe and communicated with a water inlet pipe of the water pumping well; a water check valve is arranged on the water inlet pipe of the water pumping well; an outlet water check adjusting valve is arranged on the siphon pipe; and a U-shaped elbow pipe is arranged at an outlet of the siphon pipe. The water-filling type siphon drainage device applicable to the radioactive well is reliable to operate, convenient to maintain, safe to operate with less interference from external condition.

Owner:CHANGSHA DESIGN & RES INST OF CHEM IND MIN

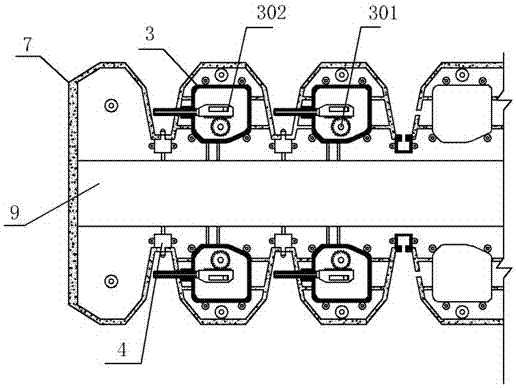

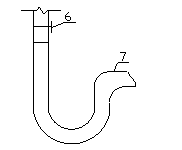

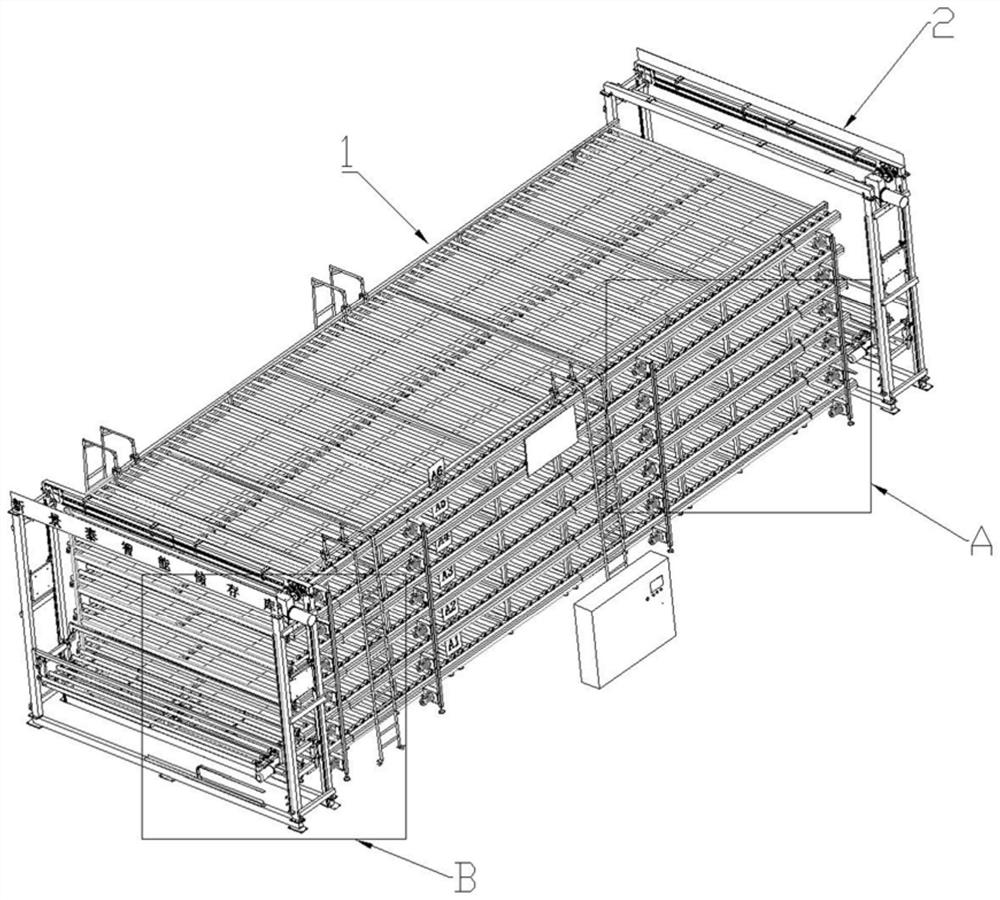

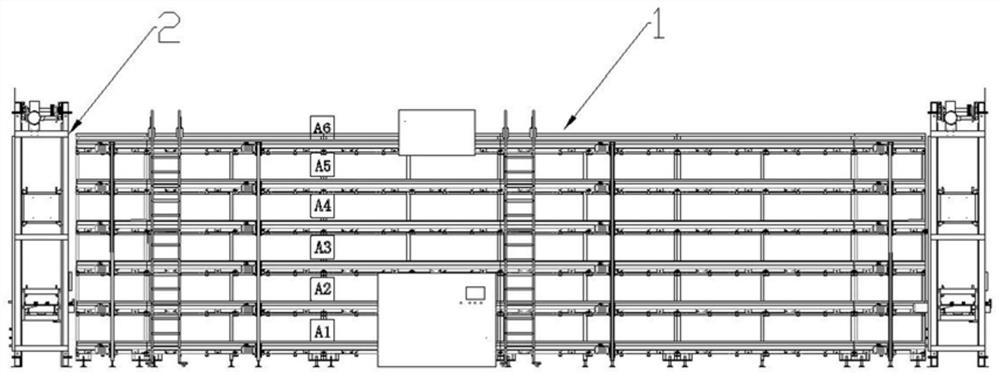

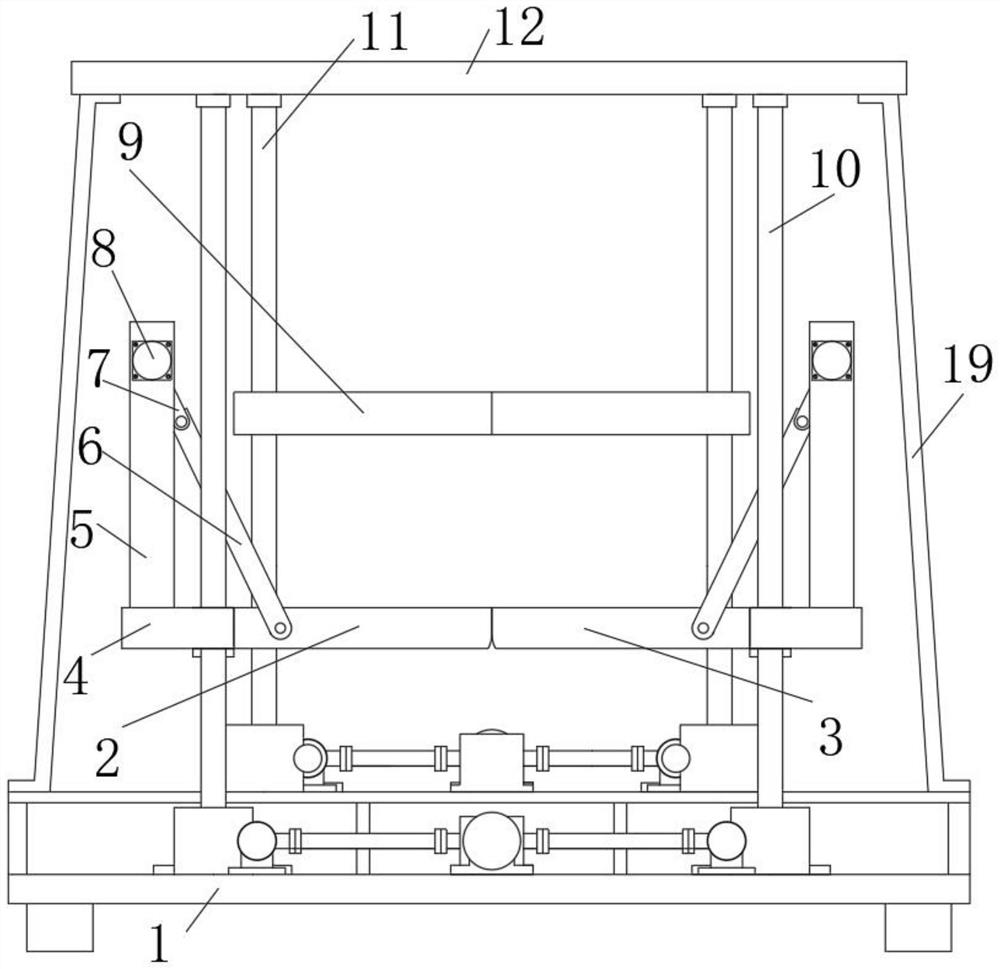

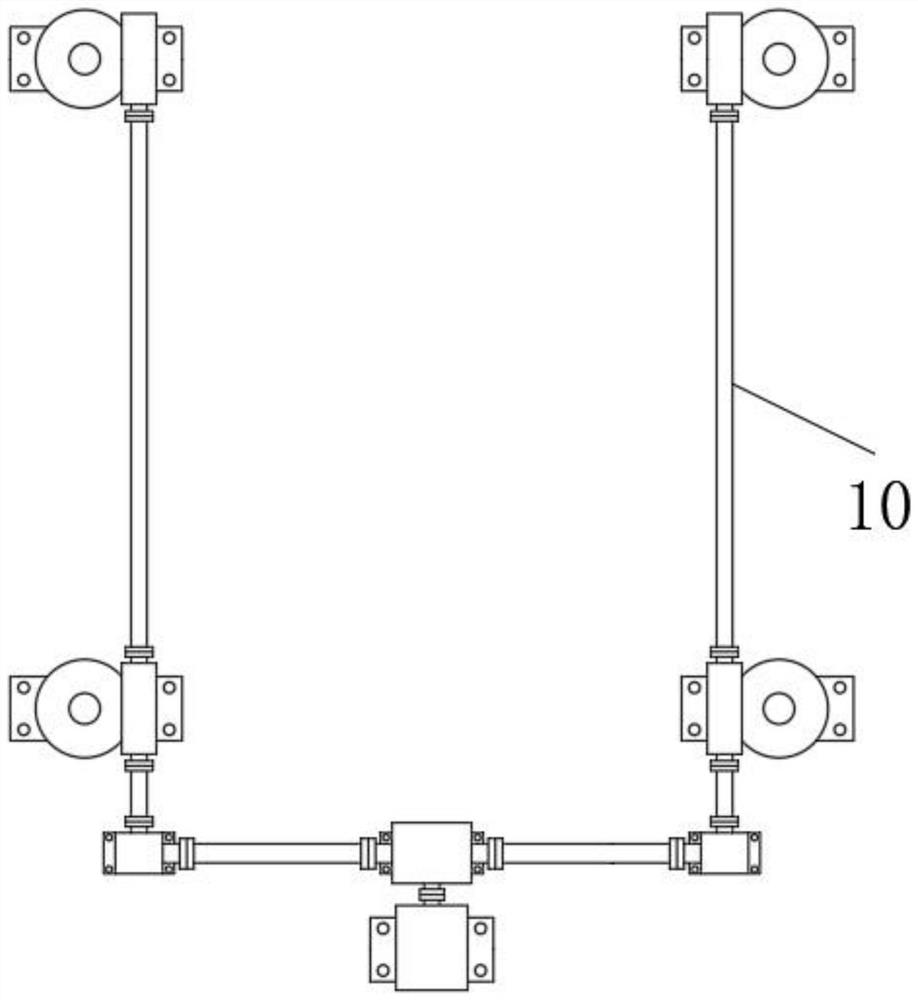

Height-adjustable parcel vibration sorting machine

InactiveCN105035703AIncrease the number of settingsSeriously affect the logistics speedConveyor partsMechanical engineering

The invention provides a height-adjustable parcel vibration sorting machine. The height-adjustable parcel vibration sorting machine comprises a height-adjustable stacking and pushing-leveling device and a vibration sorting machine which are sequentially arranged, wherein the height-adjustable stacking and pushing-leveling device is provided with a parcel entering end, an unpack conveyor belt is arranged at the parcel entering end, a plurality of bucket tipping devices are arranged above the unpack conveyor belt, and the vibration sorting device is provided with a parcel discharging end which is connected with an artificial detection buffer area. The height-adjustable parcel vibration sorting machine has the benefits as follows: constant-height and transversely-regular vibration sorting can be performed on parcels, and large quantities of parcels stacked in an overlapped manner are spread.

Owner:天津玛塔德科技有限公司

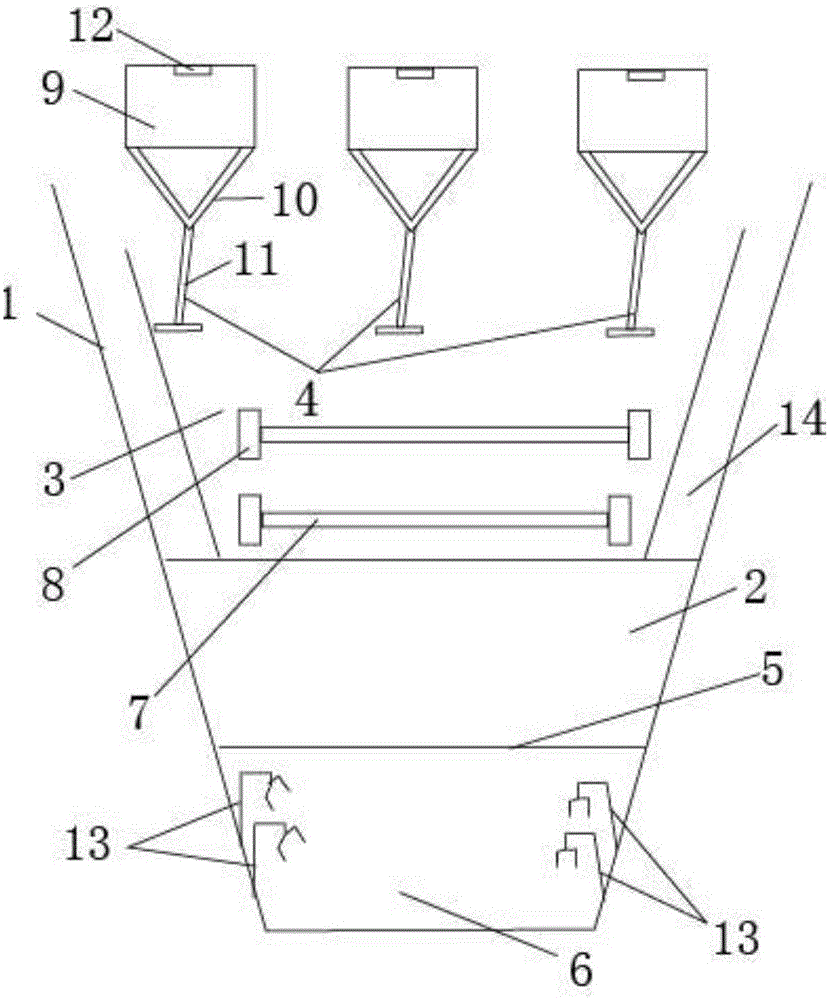

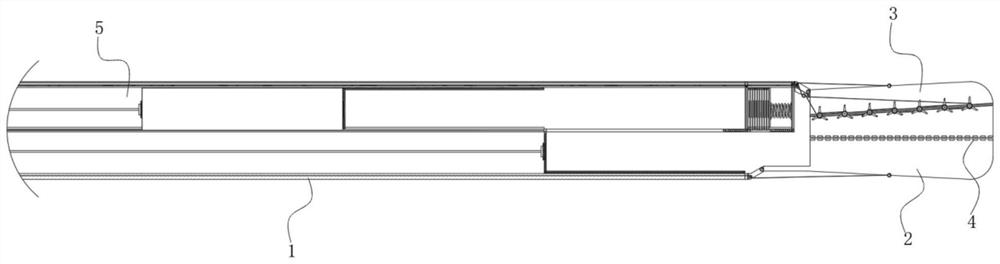

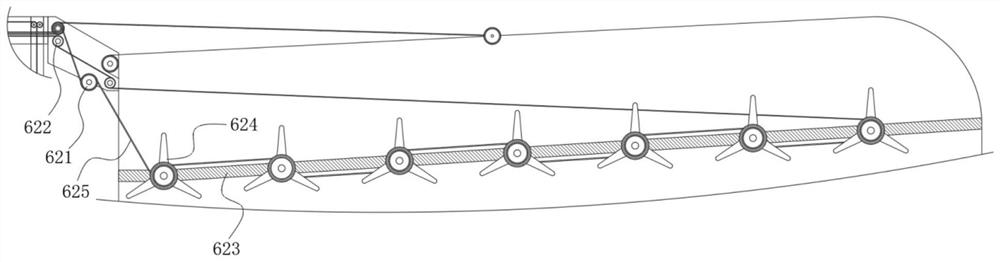

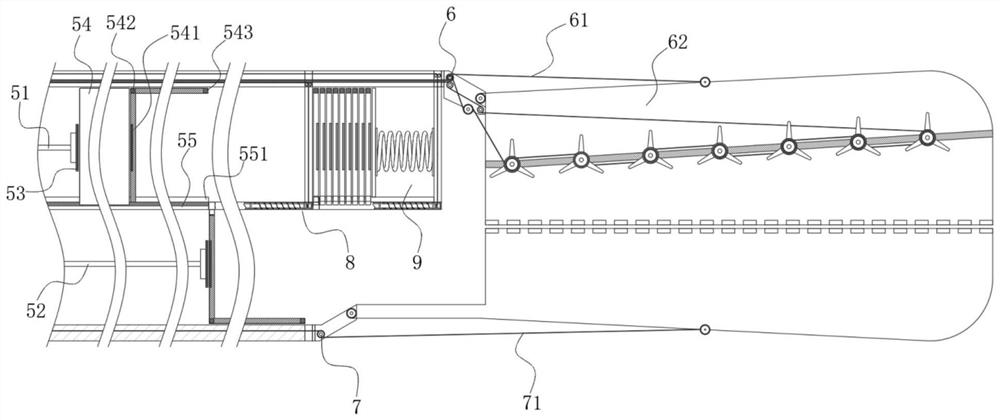

Induction heating continuous magnesium-smelting system and continuous magnesium-smelting technique

The invention discloses a set of induction heating continuous magnesium smelting device and continuous magnesium smelting process. The device includes a continuous feeding device, an induction heating reaction chamber, a magnesium steam condensing device and a continuous slagging device; wherein, the feeding device is composed of a silo and a screw feeding mechanism, and the reaction chamber is composed of an induction heating coil, a heating element, a belt The baffle plate of the hole and the slag cooling device are composed. The condensing device is composed of a baffle plate with a mesh structure, a dust settling chamber, and a magnesium steam condensing chamber. The continuous slag discharge device includes a spiral slag pushing mechanism and a slag bin. The continuous magnesium smelting process includes the continuous push of the reaction charge into the reaction chamber, the continuous condensation of magnesium vapor, and the discharge of liquid magnesium, as well as the continuous entry of reaction slag into the slag bin and slag discharge. The invention has high thermal energy utilization rate and can realize continuous production of metal magnesium at low cost.

Owner:CENT SOUTH UNIV

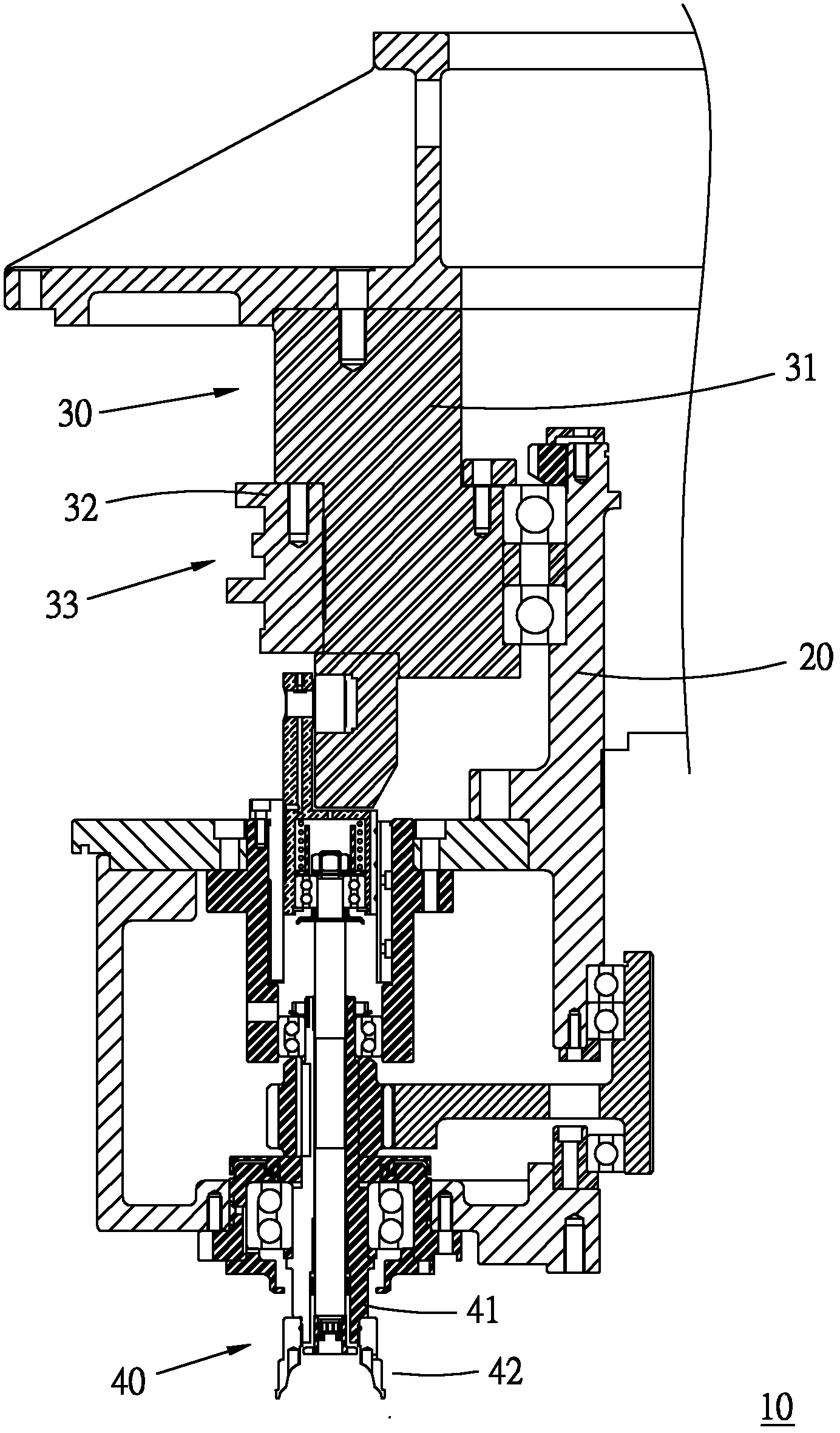

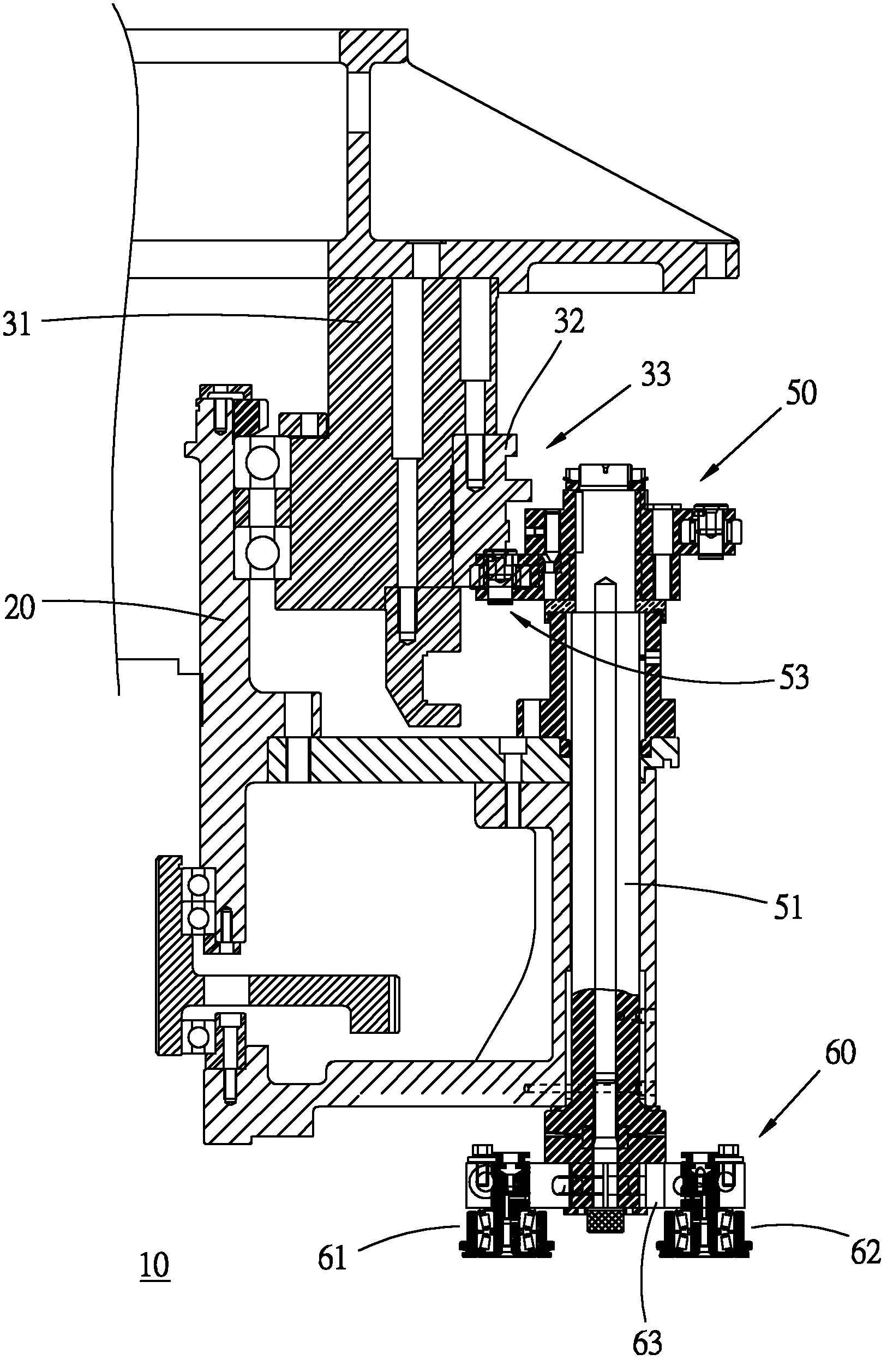

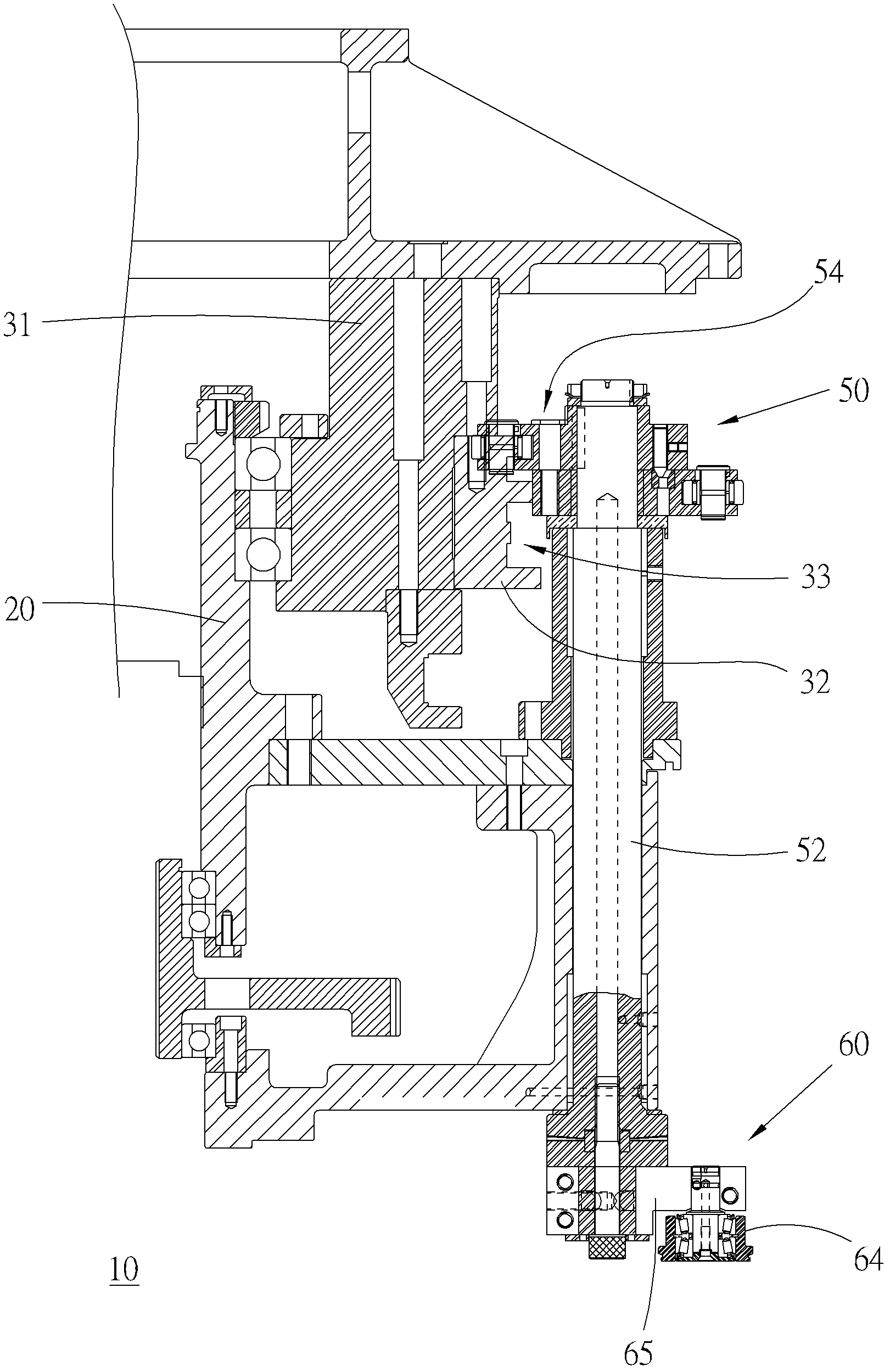

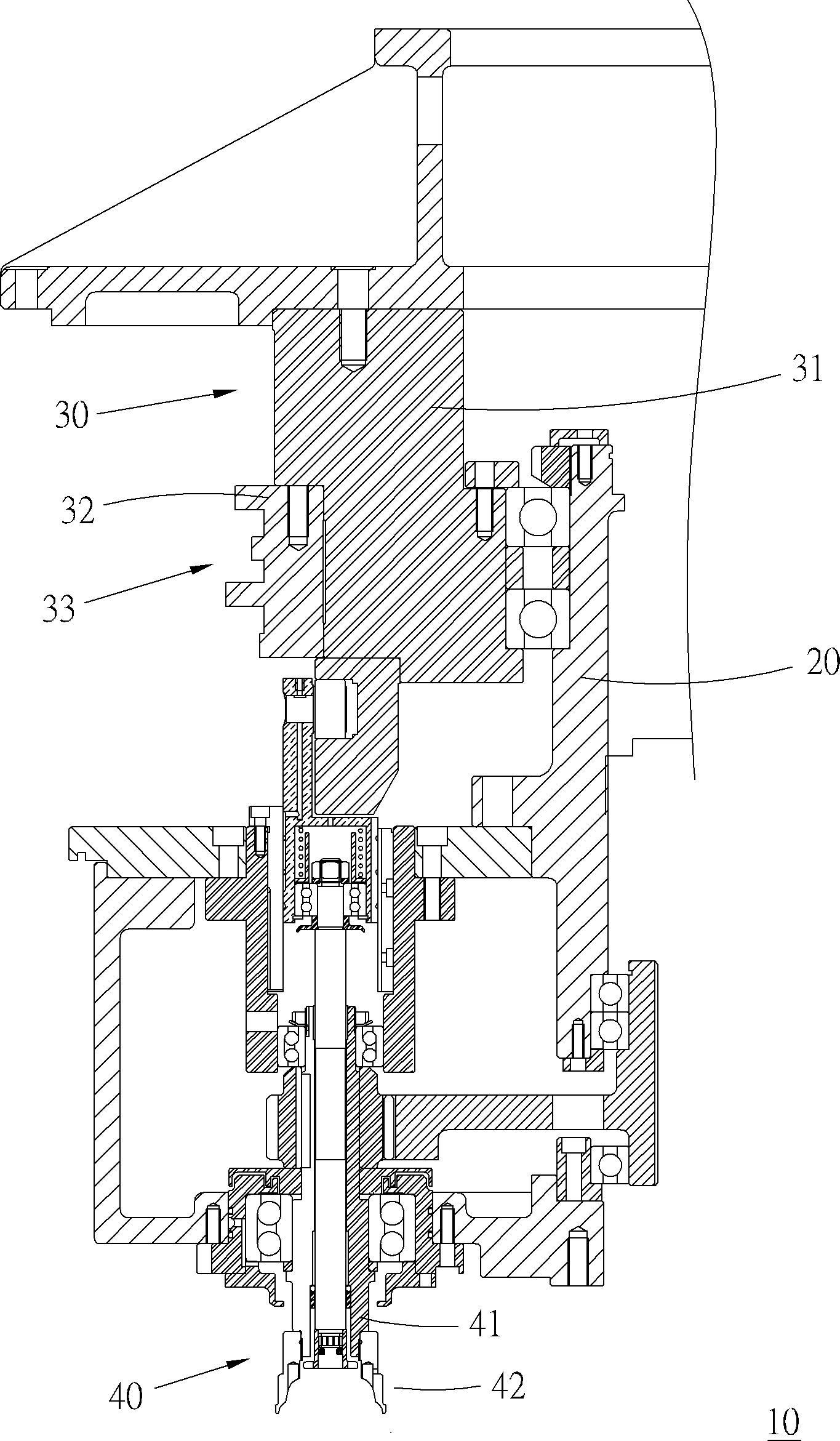

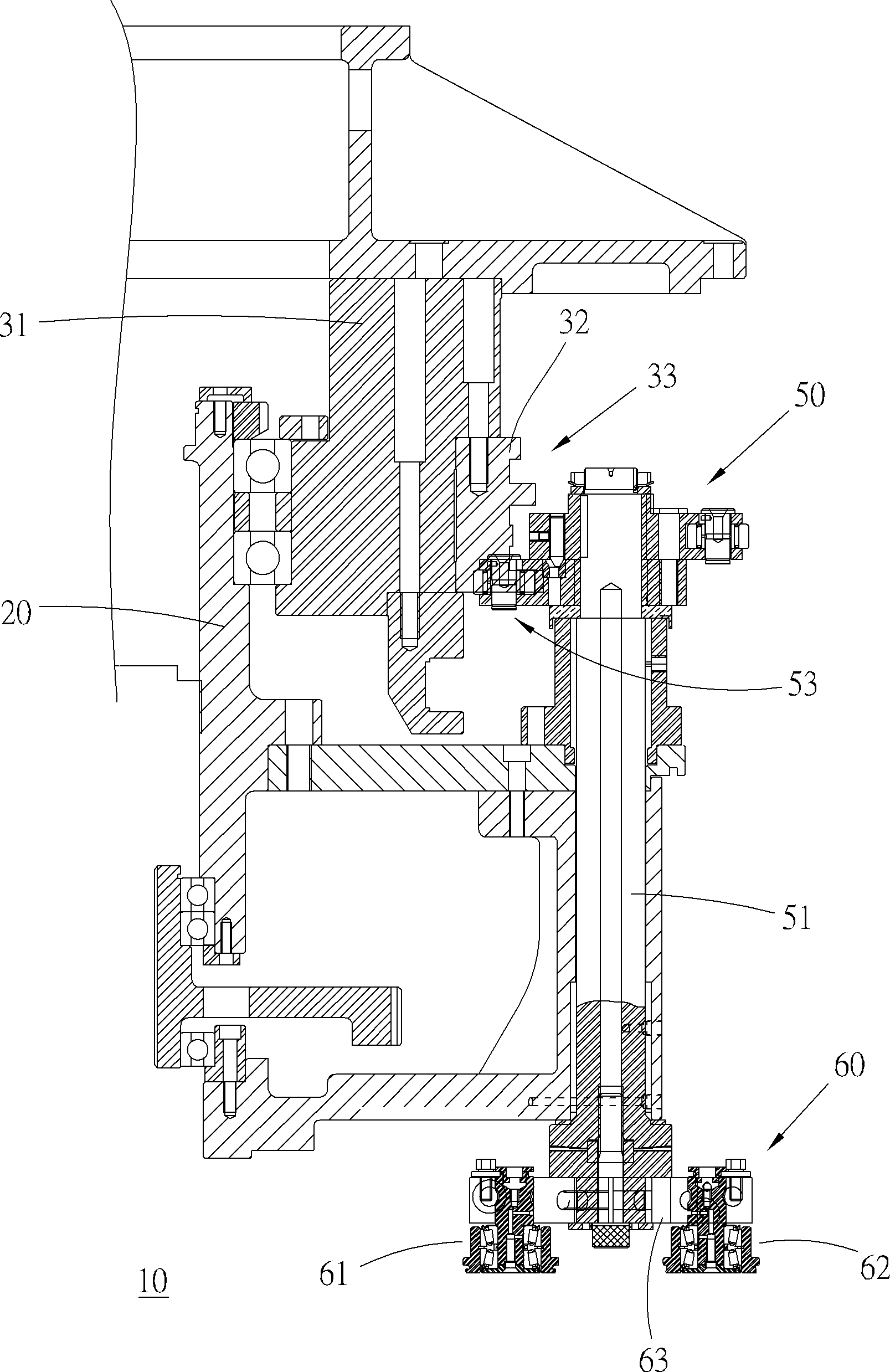

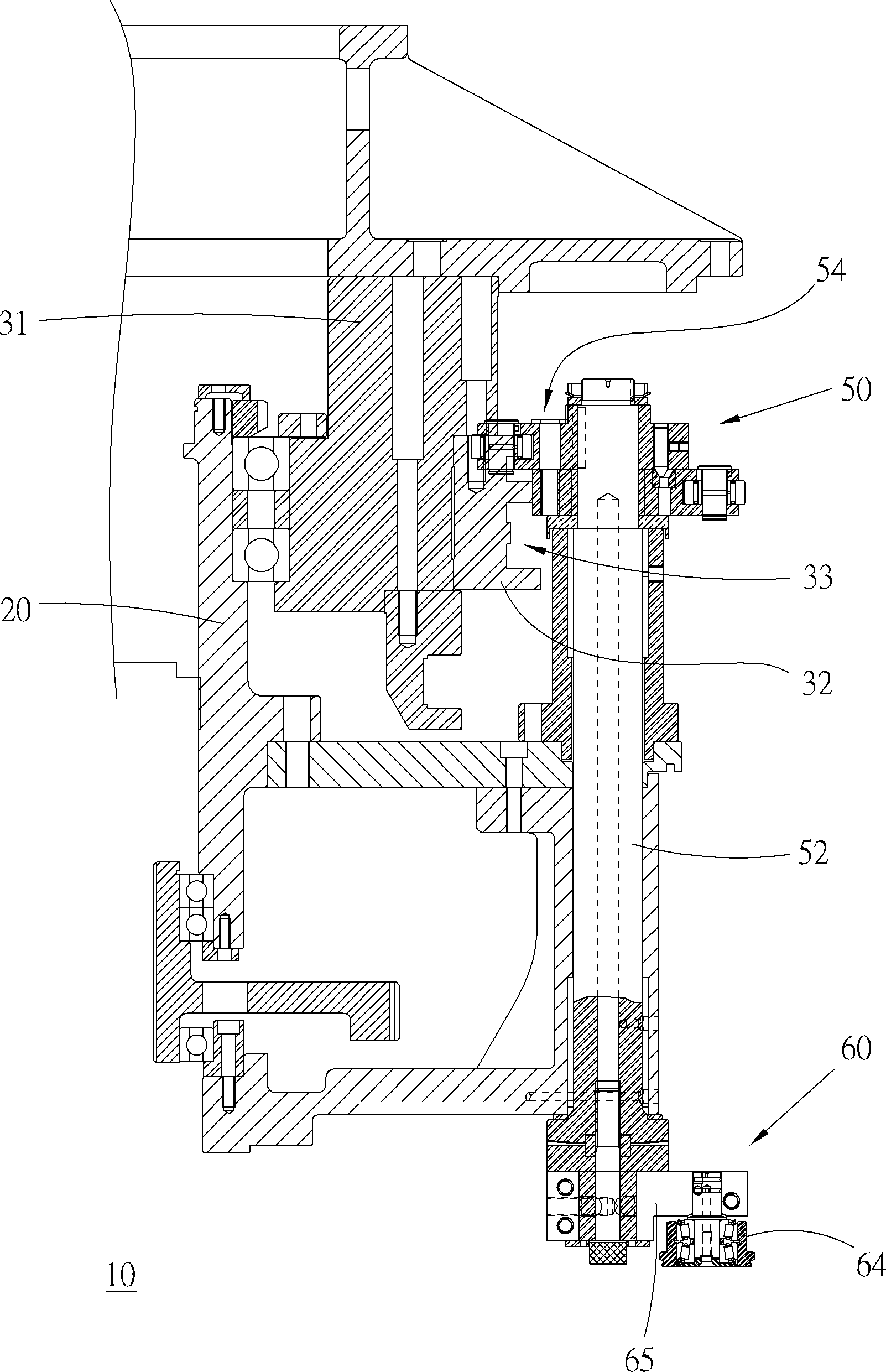

Seaming mechanism of can manufacturing machinery

ActiveCN102861833AReduce compositionIncrease the number of settingsHollow articlesEngineeringMechanical engineering

Owner:新益机械工厂股份有限公司

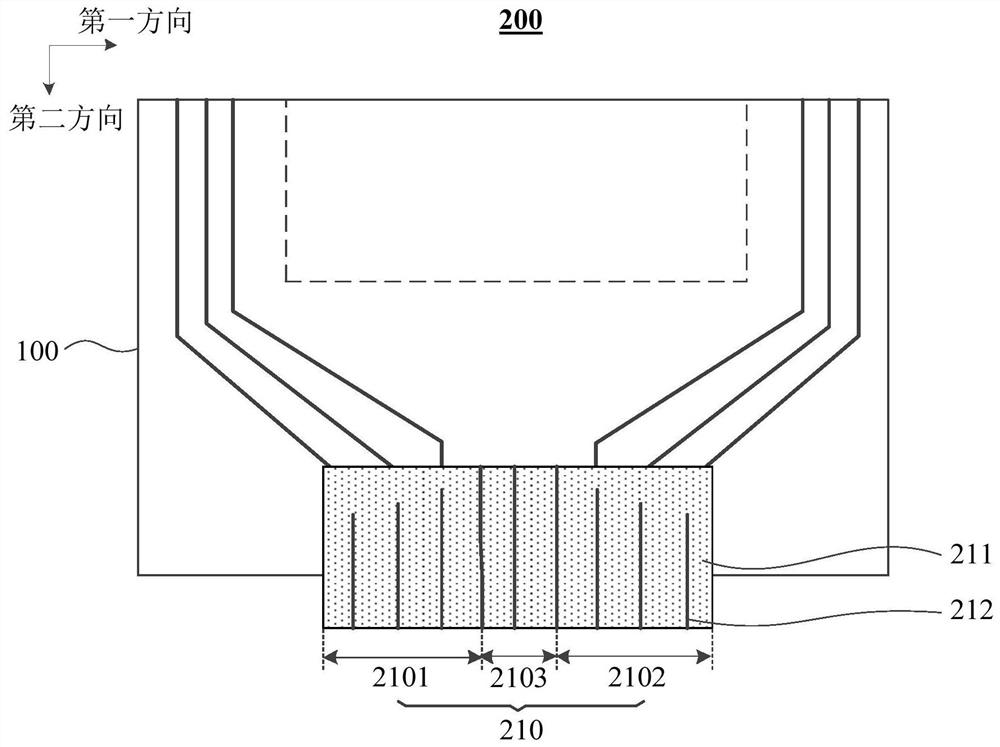

Backlight module and display device

PendingCN114488385AIncrease the number of settingsIncrease the number ofOptical light guidesIdentification meansPoint lightLight guide

The invention relates to the technical field of display, and discloses a backlight module and a display device.The backlight module comprises a back plate and a light guide plate, the back plate is provided with a containing groove, and the light guide plate is arranged in the containing groove; a containing space is formed between at least one end of the bottom wall of the containing groove and the light guide plate, and the light guide plate is provided with a plurality of light reflecting convex parts extending towards the interior of the containing space; the backlight module further comprises a plurality of point light sources arranged in the containing space, and each light reflecting convex part is used for reflecting light emitted by at least one point light source into the light guide plate to be evenly diffused. The backlight module and the display device provided by the invention have higher light emitting brightness.

Owner:CHONGQING HKC OPTOELECTRONICS TECH CO LTD +1

Horizontal type measuring apparatus for Young's modulus

InactiveCN100394160CIncrease profitIncrease the number of settingsMaterial analysis by optical meansMaterial strength using tensile/compressive forcesObservational errorYoung's modulus

A horizontal Young's modulus measurer can measure Young's modulus of steel wire conveniently by applying horizontal drawing method and utilizing the reading microscope. The present invention decreases two moduluses to be tested, so measurement and calculation are simplified and system error of measurement can be decreased.

Owner:SICHUAN UNIV

Continuous repeated sampling bronchoscope biopsy forceps

ActiveCN114343742AIncrease the number of settingsEasy to installBronchoscopesLaryngoscopesBiopsy forcepsGeneral surgery

The invention discloses a pair of continuous multi-sampling bronchoscope biopsy forceps, which comprises a round tube, a plurality of groups of independent axially pointing rope cavities are formed in the shell wall of the round tube, an upper forceps cover and a lower forceps cover are respectively hinged to the shell wall at the right end of the round tube, and a first shaft ring and a second shaft ring are respectively and rotatably mounted on the shell wall of the round tube close to the hinged ends of the upper forceps cover and the lower forceps cover; two groups of first shaft rings are coaxially and independently arranged in parallel in the front-back direction, a rotary shifting assembly is installed in the upper clamp cover, and a sampling device is installed in the portion, located on the left side of the rotary shifting assembly, of the circular pipe; the electric cutting element sheets are uniformly laid on the contact surface ends of the upper clamp cover and the lower clamp cover; the first wire rope penetrates through a group of independent rope cavities from the outside of the circular tube, is wound around the first shaft ring on the rear side by multiple circles and is connected with the middle part of the upper clamp cover; and the second wire rope penetrates through the group of rope cavities from the outer part of the circular tube, is wound around the second shaft ring for multiple circles and is connected with the middle part of the lower clamp cover.

Owner:湖南朗开医疗科技有限公司

Connector provided with combination detection unit

ActiveCN102332649BIncrease the number of settingsIncrease freedomCoupling contact membersCouplings bases/casesEngineeringMechanical engineering

Owner:JST MFG CO LTD

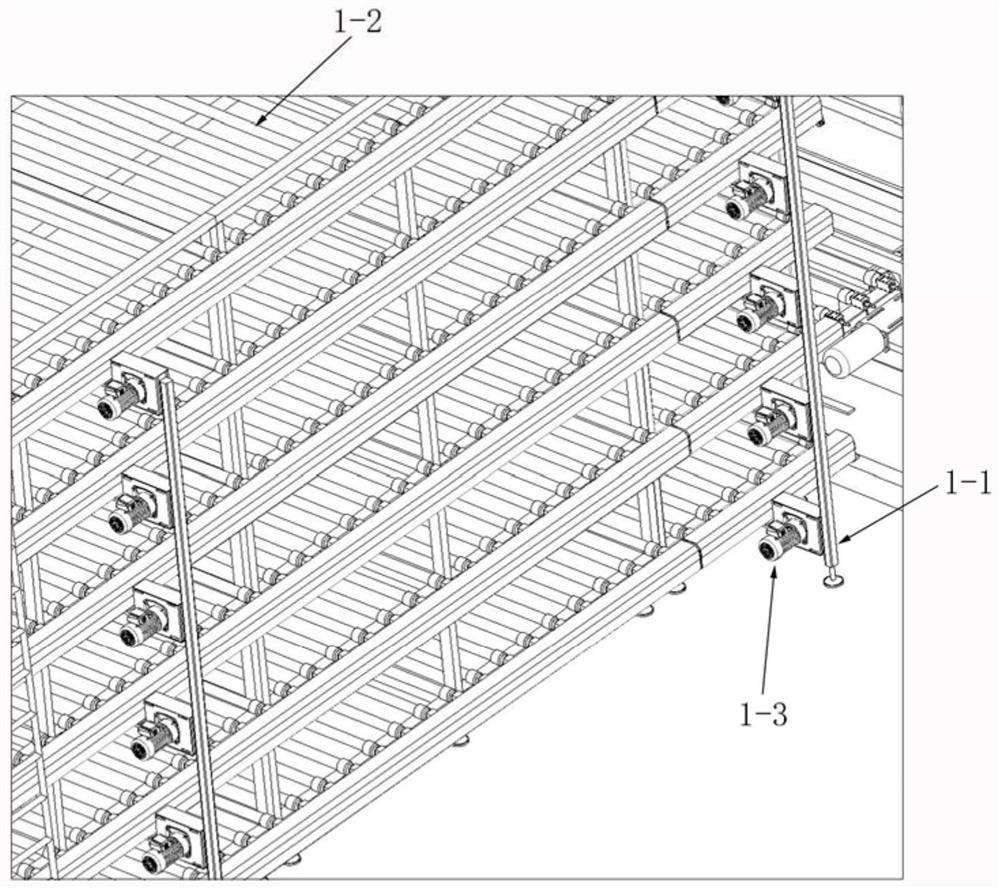

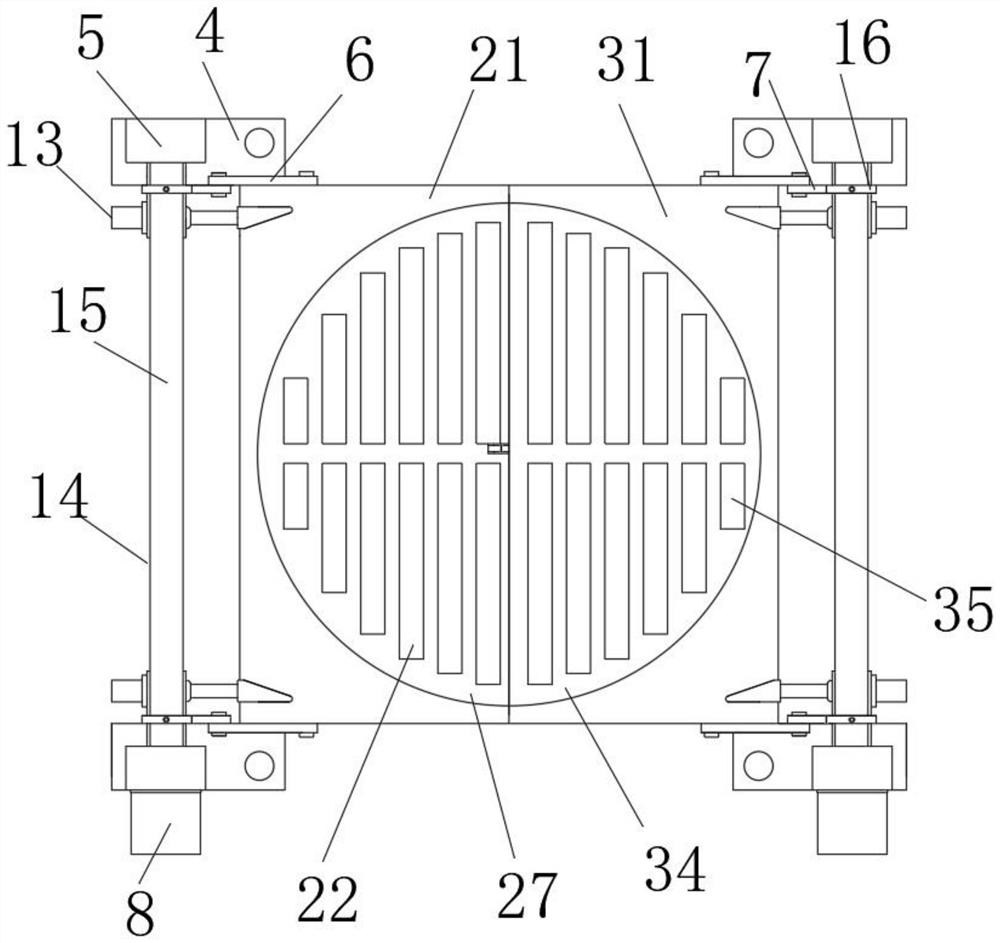

Closestool storage warehouse

PendingCN111674802AAchieve storageReduce manufacturing costDischarging arrangementConveyorsElectric machineryProcess engineering

The invention discloses a closestool storage warehouse. The closestool storage warehouse comprises a storage roller table and lifters arranged at the two ends of the storage roller table correspondingly, the two lifters are used for lifting feeding and lifting discharging correspondingly, the storage roller table comprises a first rack, a plurality of rollers rotationally mounted on the first rack, and first motors for driving the rollers, and all the rollers are used for jointly forming a plurality of placing layers. According to the closestool storage warehouse, the height space in a workshop can be fully utilized, closestool green bodies are stored overhead, the space utilization rate is high, and the storage efficiency is high; and meanwhile, mechanization and intellectualization can be achieved conveniently, manpower and material resources are saved, and then the production cost of closestools is reduced.

Owner:FOSHAN SANSHUI YINGJIE PRECISION MACHINERY

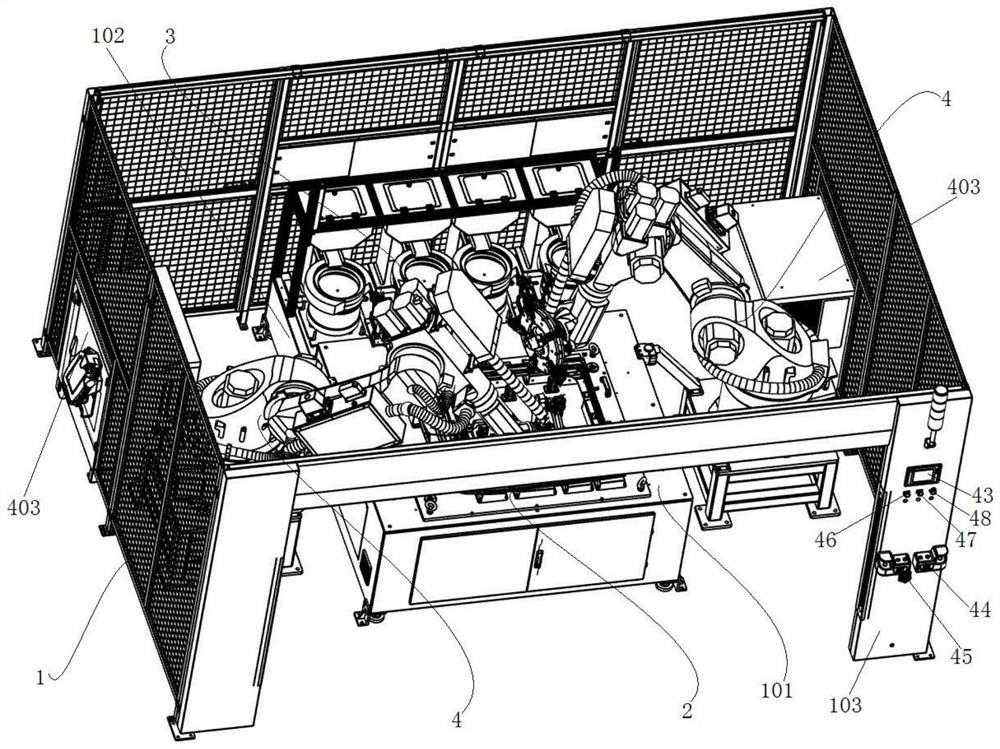

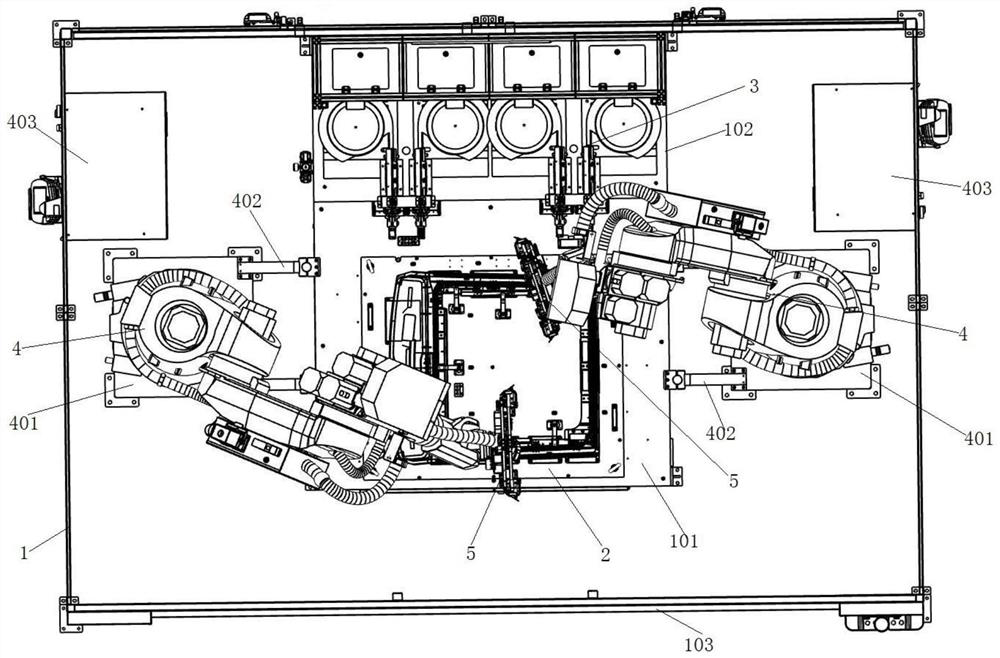

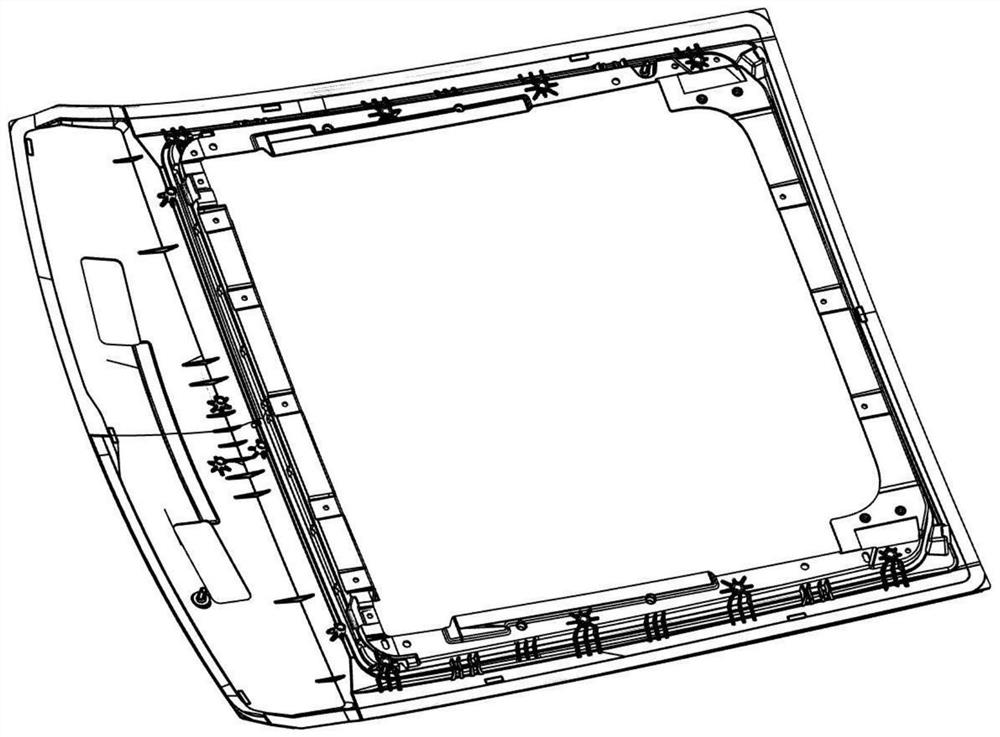

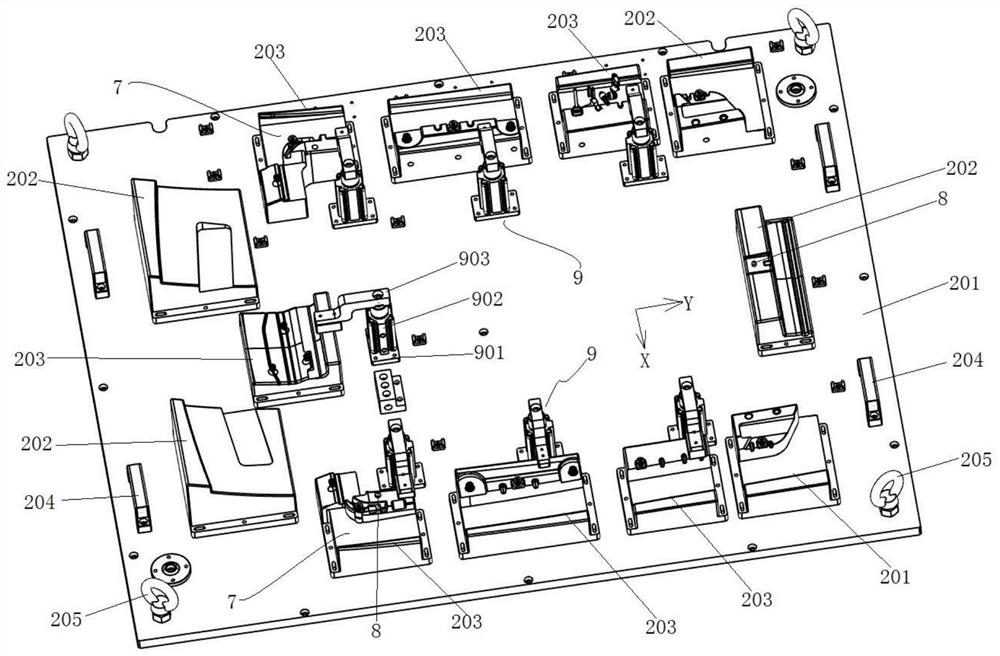

Nut insert hot melting workstation arrangement structure and hot melting process method

The invention discloses a nut insert hot melting workstation arrangement structure and a hot melting process method. The nut insert hot melting workstation arrangement structure comprises a workstation frame and a portal frame on the front face of the workstation frame, and a primary workbench and a secondary workbench are arranged in the middle of the workstation frame; the primary workbench is provided with a positioning clamp assembly, and the secondary workbench is provided with an automatic feeding assembly; robots are arranged on the two sides of the primary workbench correspondingly, and the free ends of the robots are connected with material taking assemblies; and a controller is arranged in the portal frame, a man-machine interaction screen is arranged on the outer side wall of the portal frame, the man-machine interaction screen is connected with the controller, and a hot melting starting button is arranged below the man-machine interaction screen. The nut insert hot meltingworkstation arrangement structure is simple and compact, the connection relation and the position relation between components can be fully utilized, integration of multiple procedures and multiple operation parts is conducted, an independent machining space is formed, and the safety is high; and by adopting an automatic control technology, the welding operation is simplified, and the welding efficiency and the welding quality are improved.

Owner:HUBEI UNIV OF ARTS & SCI

Warehouse logistics management rapid sorting device

The warehouse logistics management rapid sorting device comprises a base, supporting rod pieces and a top plate, the supporting rod pieces are fixedly installed at the four corners of the upper end of the base through screws, the upper ends of the supporting rod pieces are fixedly connected with the top plate through screws, and the base is divided into an upper layer structure and a lower layer structure; a first synchronous lead screw lifting platform is fixedly installed on the lower layer of the base through bolts, a second synchronous lead screw lifting platform is fixedly installed on the upper layer of the base through bolts, and the tops of the first synchronous lead screw lifting platform and the second synchronous lead screw lifting platform are rotationally connected with a top plate. The splicing sorting platform and the integrated sorting platform are arranged and matched with the first synchronous lead screw lifting platform, the second synchronous lead screw lifting platform and the driving component, sorting work can be conducted on the upper-level conveying lines on the upper layer and the lower layer at the same time, and multi-level distribution of the lower-level conveying lines in the space can be achieved; and the rapid sorting work of various products can be met, the sorting efficiency is improved, time is saved, and customers can be better served.

Owner:SHIJIAZHUANG UNIVERSITY +1

Seaming mechanism of can manufacturing machinery

ActiveCN102861833BReduce compositionIncrease the number of settingsHollow articlesEngineeringMechanical engineering

Owner:新益机械工厂股份有限公司

High-resolution rotation-speed measuring device

InactiveCN101907633BImprove measurement resolutionIncrease the number of settingsLinear/angular speed measurementSignal conditioningProjection plane

The invention discloses a high-resolution rotation-speed measuring device. In each rotation-speed collecting unit, rectangular light-transmitting holes are evenly distributed on the end surface of a rotating disk along a circumferential direction, the rectangular light transmitting holes pass through a circle center of the rotating disk along a center line of a length direction, a sensing device approaches to the rectangular light transmitting holes of the rotating disk, the output end of the sensing device is connected with the input end of a signal conditioning device through a signal wire,the signal conditioning device is used for converting signals output by the sensing device into square signals, the output end of the signal conditioning device is connected with a computer through the signal wire; the end surfaces of the rotating disks in each rotation-speed collecting unit are mutually parallel, and a connecting wire of the circle centers of the rotating disks is a straight line and is perpendicular to the end surface of each rotating disk; on a projection plane which is perpendicular to the connection wire, an included angle is formed between the center line of the rectangular light-transmitting holes of the rotating disks along the length direction and an orthogonal projection on the projection plane, and the included angles of the adjacent orthogonal projections of the center line are equal and are greater than zero. The invention can ensure that the measurement resolution is increased exponentially.

Owner:ZHEJIANG UNIV

Nut insert hot melting workstation

InactiveCN112477156AIncrease flexibilityQuality improvementDomestic articlesAutomatic controlEngineering

The invention discloses a nut insert hot melting workstation, which comprises a workbench arranged in the workstation; a positioning clamp assembly is arranged on the workbench; an automatic feeding assembly is arranged on one side of the workbench; a plurality of robots are arranged on the other two sides of the workbench, and material taking assemblies are arranged at free ends of the robots; and the material taking assembly clamps inserts on the automatic feeding assembly and moves the inserts to the position above the positioning clamp assembly to be subjected to hot melting operation. Thenut insert hot melting workstation provided by the invention can automatically conduct nut insert welding work, the automation degree, the intelligent degree and the flexibility are good, all movingparts can move independently or cooperatively, and no movement interference is generated between the moving parts; by adopting an automatic control technology, the welding operation becomes easy and simple, the welding efficiency is high, and the quality is better; and the whole layout is simple and compact, the occupied area is small, no pollution or waste exists in the welding process, noise islow, and the working environment is simple and environmentally friendly.

Owner:HUBEI UNIV OF ARTS & SCI

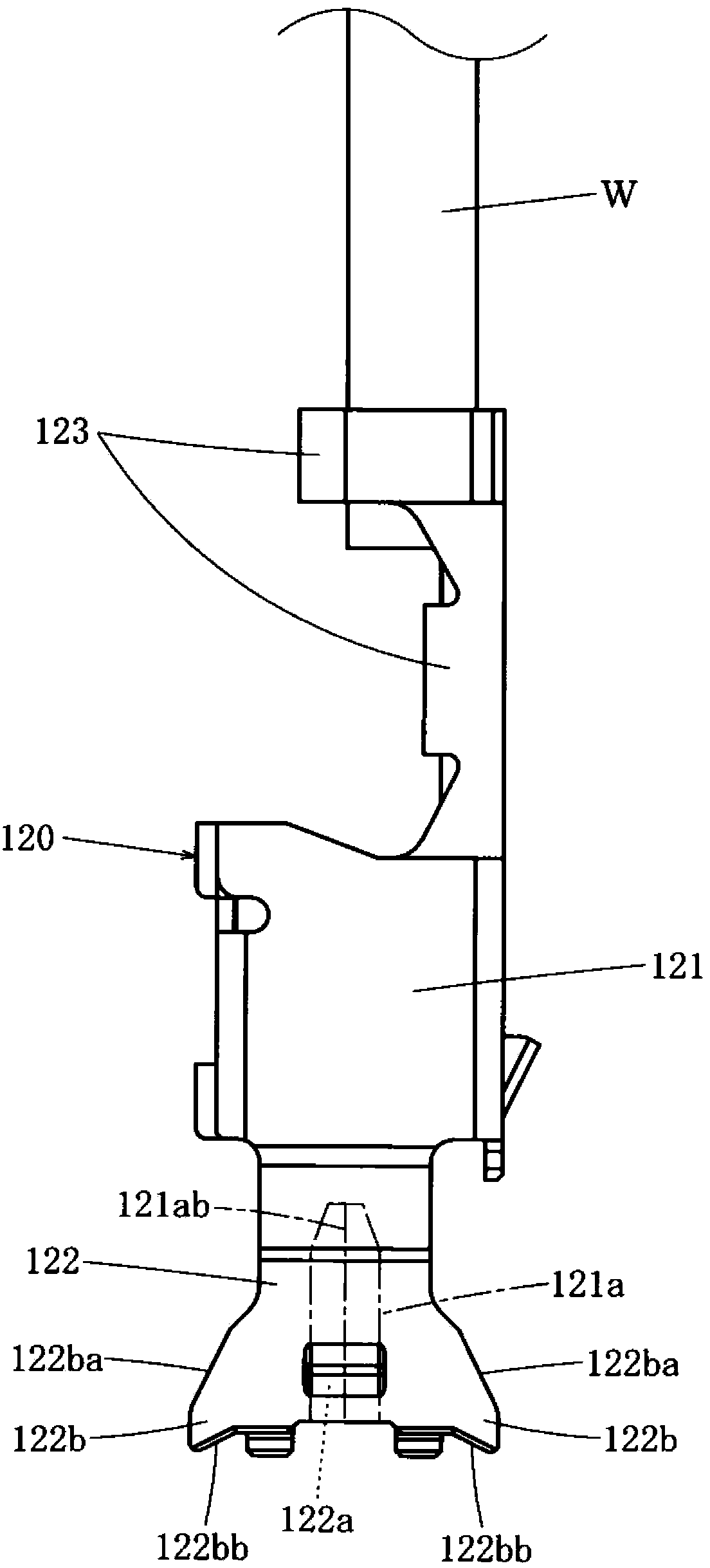

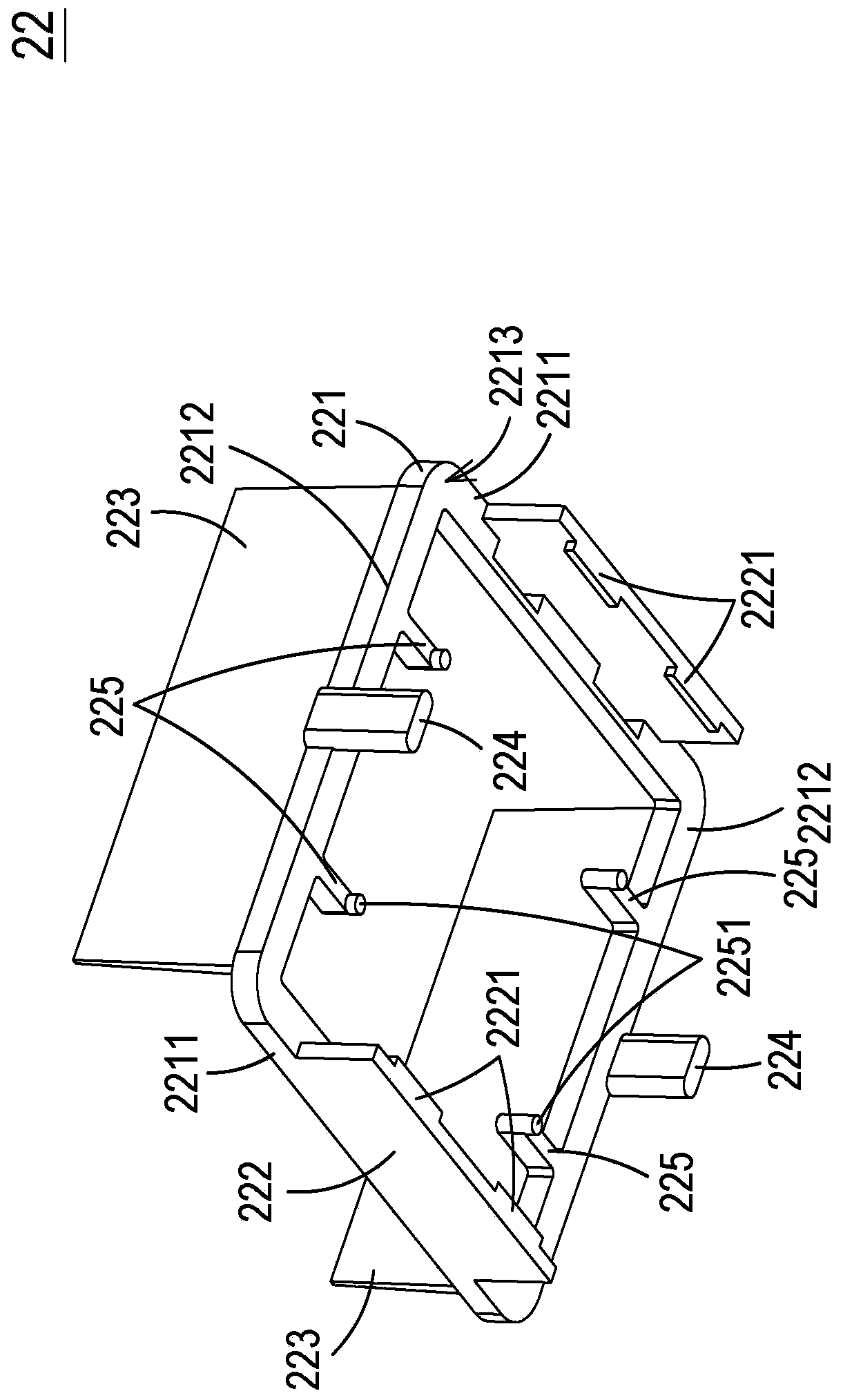

Electrical connector with binding detection unit

ActiveCN103457106BIncrease freedomImprove production efficiencyIncorrect coupling preventionEngineeringElectrical connector

PROBLEM TO BE SOLVED: To provide electric connectors that comprise a detection function of complete fitting, can make both electric connectors compact, improve the installation number of contacts and the freedom of installation positions, and improves manufacturing efficiency and the freedom of material selection without requiring a circuit exclusively for conduction detection.SOLUTION: An electric connector includes coupling detection means which is configured that, in an insertion process, from before a contact part 222 contacts with a contact point 122a until insertion length L of the contact part to a passage space 121a reaches a setting value L1 for an insertion process, a wide part 231 of a second plate 230 pushes a guide protrusion piece 122b out to the width direction outer side, elastically deforms a first plate 122 to the width direction outer side of the passage space, ousts the contact point from the passage space, and blocks contact between the contact part and contact point, and when the insertion length exceeds the setting value for the insertion process, the wide part passes the guide protrusion piece to an opposite fitting side, the first plate deviates to the width direction inner side by its restitutive force, and the contact between the contact part and contact point starts.

Owner:JST MFG CO LTD

Backlight module, assembly method thereof and liquid crystal display using backlight module

InactiveCN101630091BIncrease layout spaceReduce difficultyLighting support devicesElectric circuit arrangementsLiquid-crystal displayLight guide

The invention discloses a backlight module, an assembly method thereof and a liquid crystal display using the backlight module. The backlight module at least comprises: a light guide panel; a shell which clamps the light guide panel and forms an accommodating space with the light guide panel; at least one light emitting diode light bar arranged in the accommodating space and provides at least one light beam that enters the light guide panel. The light emitting diode light bar at least comprises a flexible circuit board and a plurality of light emitting diodes; and the flexible circuit board at least comprises a first part and at least two second parts, wherein the light emitting diodes are arranged on the first part of the flexible circuit board and the second parts are overlapped with each other. The difficulties in the assembly of the backlight module can be reduced.

Owner:INNOLUX CORP

Fastening components with low wind pressure loss, heat dissipation components and combined structure with chipset

InactiveCN107104083BImprove cooling efficiencyPrevent escapeSemiconductor/solid-state device detailsSolid-state devicesThermodynamicsEngineering

The invention discloses a low-wind-pressure-loss buckling component, a heat radiation component and a combination structure of the heat radiation component and a chip set. The heat radiation component comprises a heat radiator and the buckling component. The heat radiator comprises a baseplate and multiple heat radiating bodies. The buckling component comprises a rectangular frame, multiple first side plates and multiple flow guide plates. The rectangular frame comprises two first beam bodies, two second beam bodies, a first surface and a second surface, and the first beam bodies and the second beam bodies are defined in a connection way to form a hollow area so that multiple heat radiating bodies are enabled to be arranged in the hollow area in a penetration way. The multiple first side plates extend out of the two first beam bodies of the rectangular frame. The multiple flow guide plates extend out of the second beam bodies of the rectangular frame.

Owner:ENZOTECH CORP

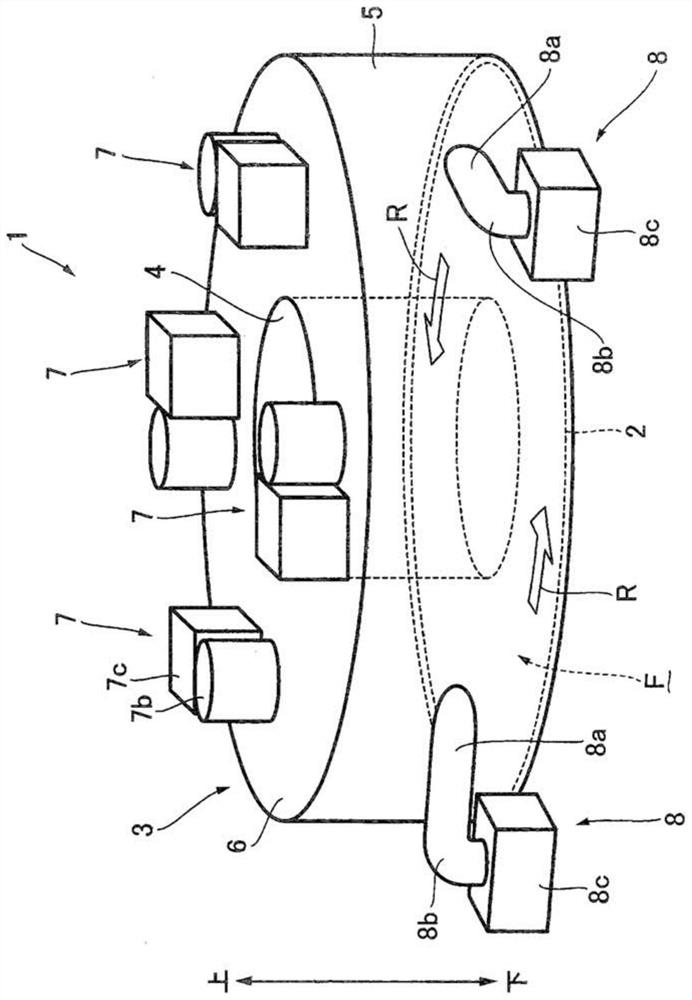

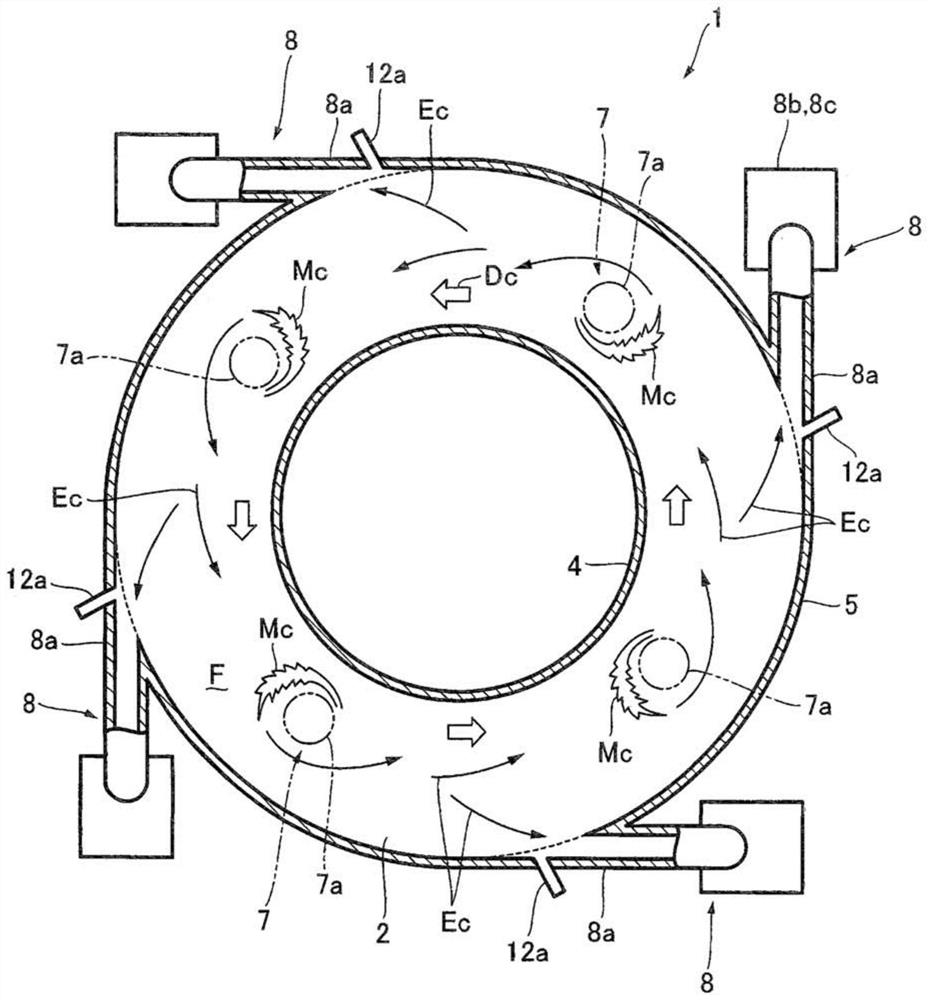

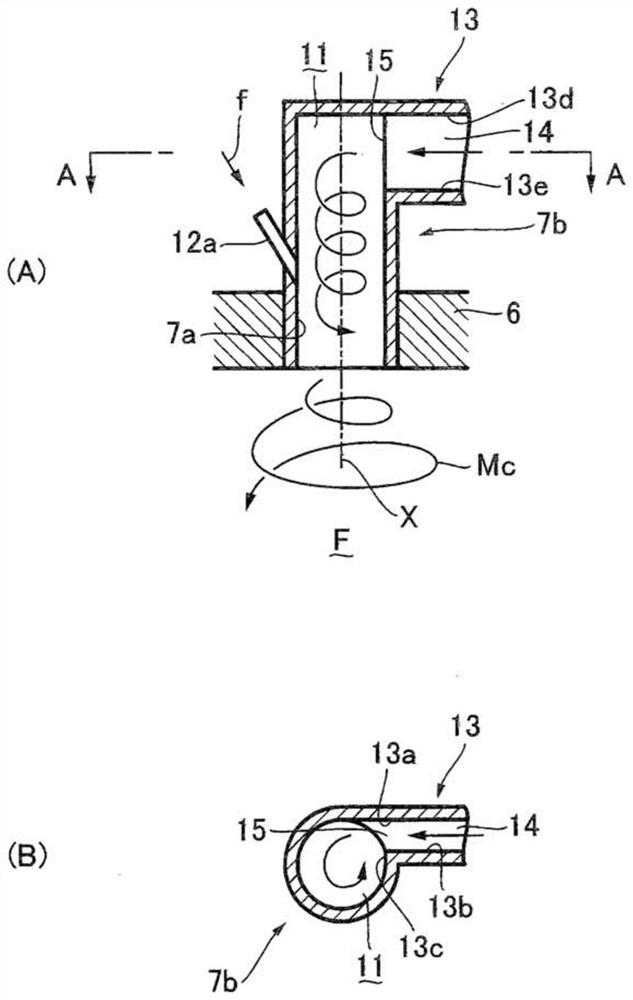

Turn on the bottom furnace and its renovation method

ActiveCN109387076BImprove the mixing effectUniform temperature distributionFurnace componentsIndirect carbon-dioxide mitigationCombustionHearth

The present invention provides a rotary hearth furnace and its modification method. The rotary hearth furnace is based on the use of regenerative burners, and can fully exert its energy-saving effect while improving the agitation of the furnace gas in the furnace to make the furnace The internal temperature distribution is uniform, and the top can be used to increase the installation space of the burner, and the number of burners that can be installed can be increased to ensure a larger combustion volume than before. In the rotary hearth furnace (1) provided with the rotary hearth (2) in the furnace F surrounded by at least the top (6) and the cylindrical outer peripheral wall (5), the top is equipped with The regenerative top burner (7) installed in the outer peripheral wall is equipped with a regenerative peripheral wall burner ( 8).

Owner:CHUGAI RO CO LTD

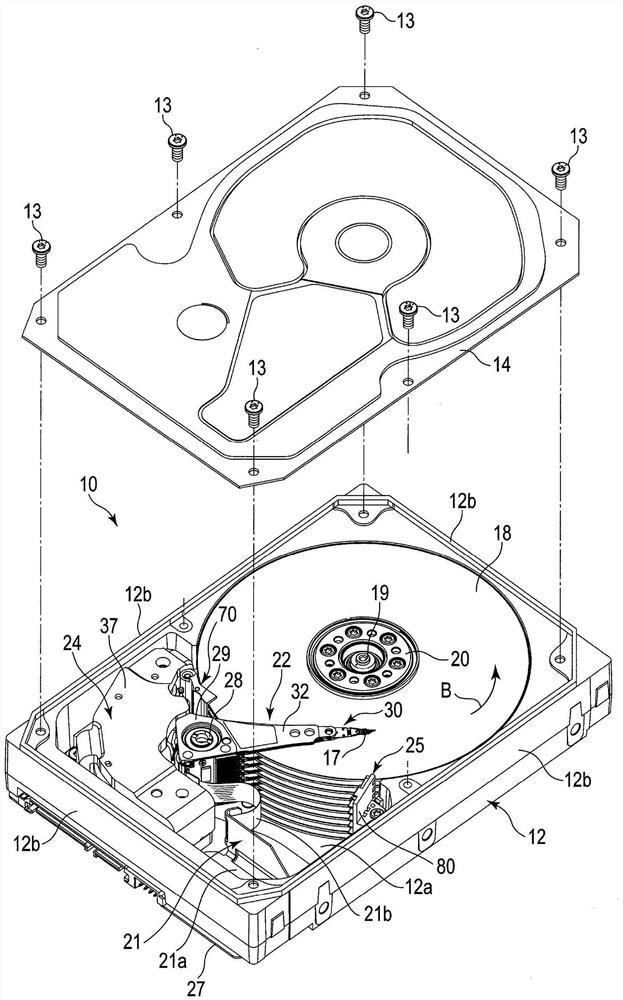

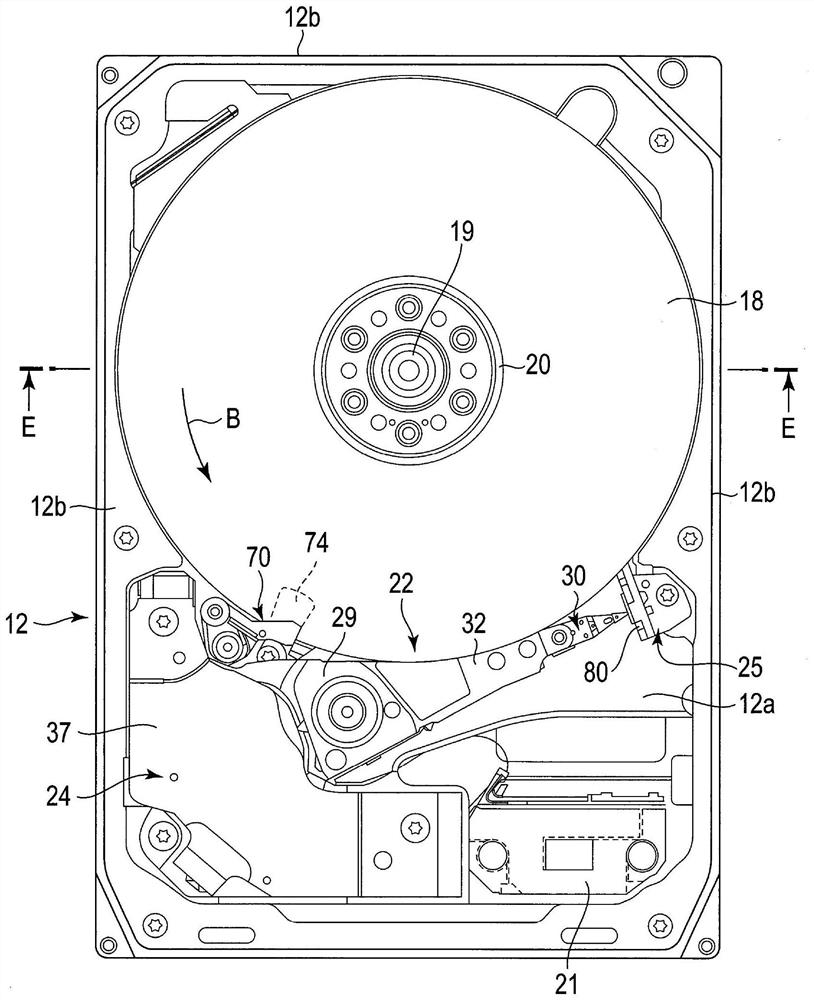

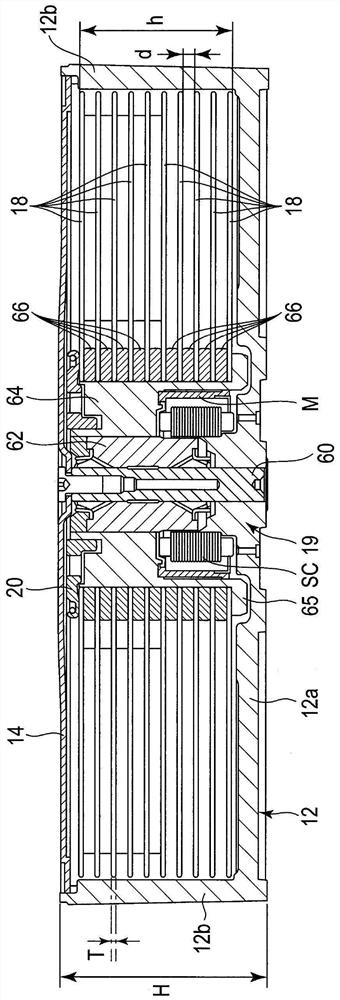

disk device

ActiveCN111540386BIncrease the number of settingsDriving/moving recording headsArm with actuatorsDisks (device)Universal joint

Owner:KK TOSHIBA +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com