Intensive oily sludge processing prying tool

An intensive, oily sludge technology, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, etc., can solve the problem of harming personal and environmental safety, high treatment cost and complex process and other problems, to achieve the effect of improving separation efficiency and recovery efficiency, high separation efficiency and good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

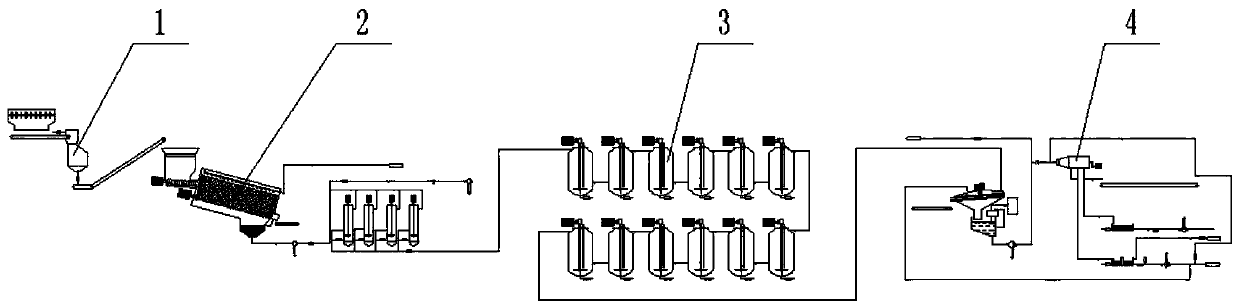

[0053] Such as Figure 1-11 As shown, an intensive oil sludge treatment skid includes a pre-sludge pretreatment device 1, a post-sludge pretreatment device 2, an intensive treatment device 3 and an oil-cement separation device 4, and the pre-sludge pretreatment device 1 is connected to the post-sludge pretreatment device 2; the post-sludge pretreatment device 2 is connected to the intensive treatment device 3; the intensive treatment device 3 is connected to the oil-cement separation device 4.

specific Embodiment approach 2

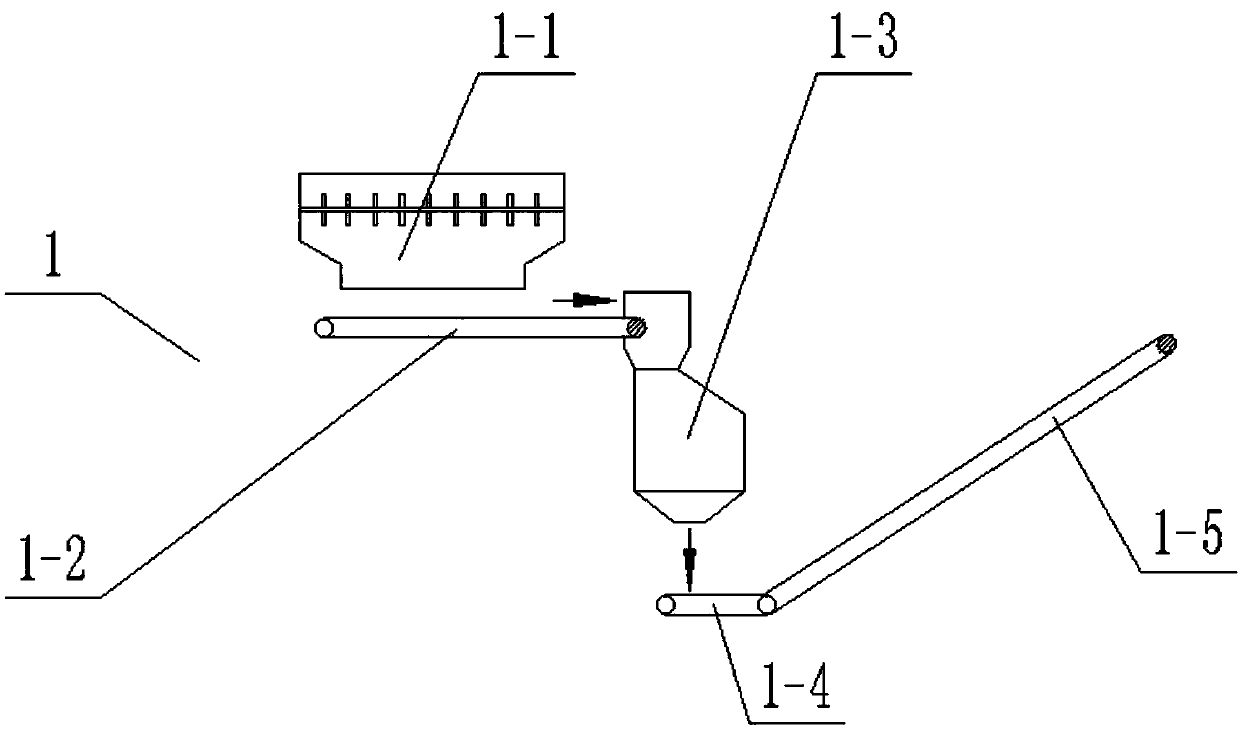

[0054] The pre-sludge pretreatment device 1 includes a shearing machine 1-1, a belt conveyor I1-2, an upper and lower double-roll crusher 1-3, a belt conveyor II1-4 and a belt conveyor III1-5, and the shears The cutting machine 1-1 is arranged on the upper end of the belt conveyor I1-2, and the discharge port of the shearing machine 1-1 is set up against the belt on the belt conveyor I1-2; the right end of the belt conveyor I1-2 is inserted into To the upper end of the upper and lower double-roll crusher 1-3; the upper and lower double-roll crusher 1-3 is arranged on the upper end of the belt conveyor II1-4, and the discharge port of the upper and lower double-roll crusher 1-3 is directly opposite to the belt conveyor The belt conveyor II1-4 is set; the right end of the belt conveyor II1-4 is connected to the belt conveyor III1-5; the belt conveyor I1-2 and the belt conveyor II1-4 are horizontally arranged belt conveyors; The belt conveyor III1-5 is an inclined belt conveyor; ...

specific Embodiment approach 3

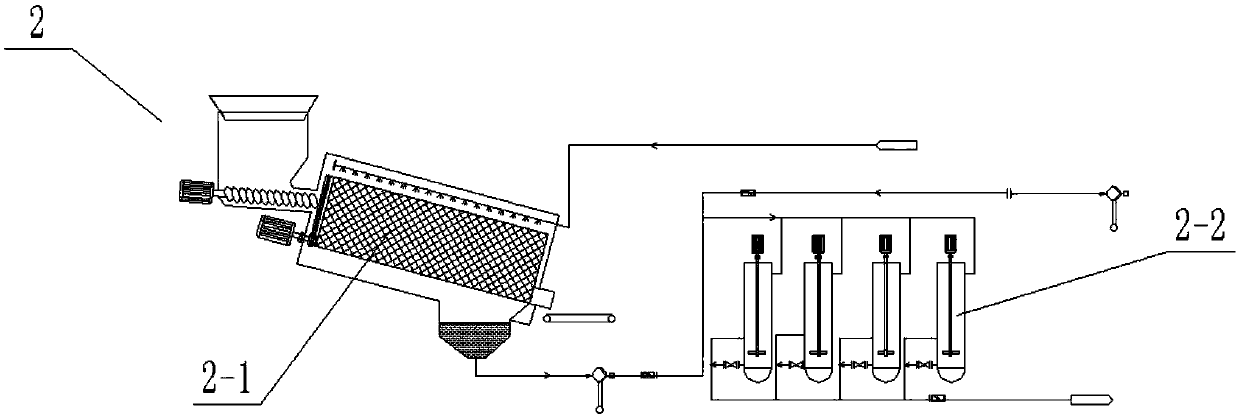

[0055] Such as Figure 1-11As shown, the post-sludge pretreatment device 2 includes a pre-treatment device 2-1 and a post-treatment device 2-2, and the pre-treatment device 2-1 includes a solid sludge sludge feed hopper 2-1-1, a screw pusher Inclined hopper 2-1-2, screw pushing device 2-1-3, screening box 2-1-4, drum type screening machine 2-1-5, spray pipe assembly 2-1-6, mixing water tank 2 -1-7, coarse material conveyor 2-1-8, flushing water inlet pipe 2-1-9 and slurry conveying pipe 2-1-10; the solid sludge feed hopper 2-1-1 is connected and set At the rear end of the front sludge pretreatment device 1; the solid sludge feed hopper 2-1-1 is arranged at the upper end of the inner side of the spiral push slant hopper 2-1-2; the spiral push slant hopper 2- The lower end of 1-2 is connected to the left side of the screening box 2-1-4; the inner lower end of the spiral pushing inclined hopper 2-1-2 is provided with a screw pushing device 2-1-3; the screening The inner middle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com