Warehouse logistics management rapid sorting device

A sorting device, a technology for warehousing and logistics, applied in sorting and other directions, can solve the problems of inability to meet the logistics warehousing sorting work, and the types of sorting are small, and achieve the effects of improving sorting efficiency, saving time, and increasing the number of types.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

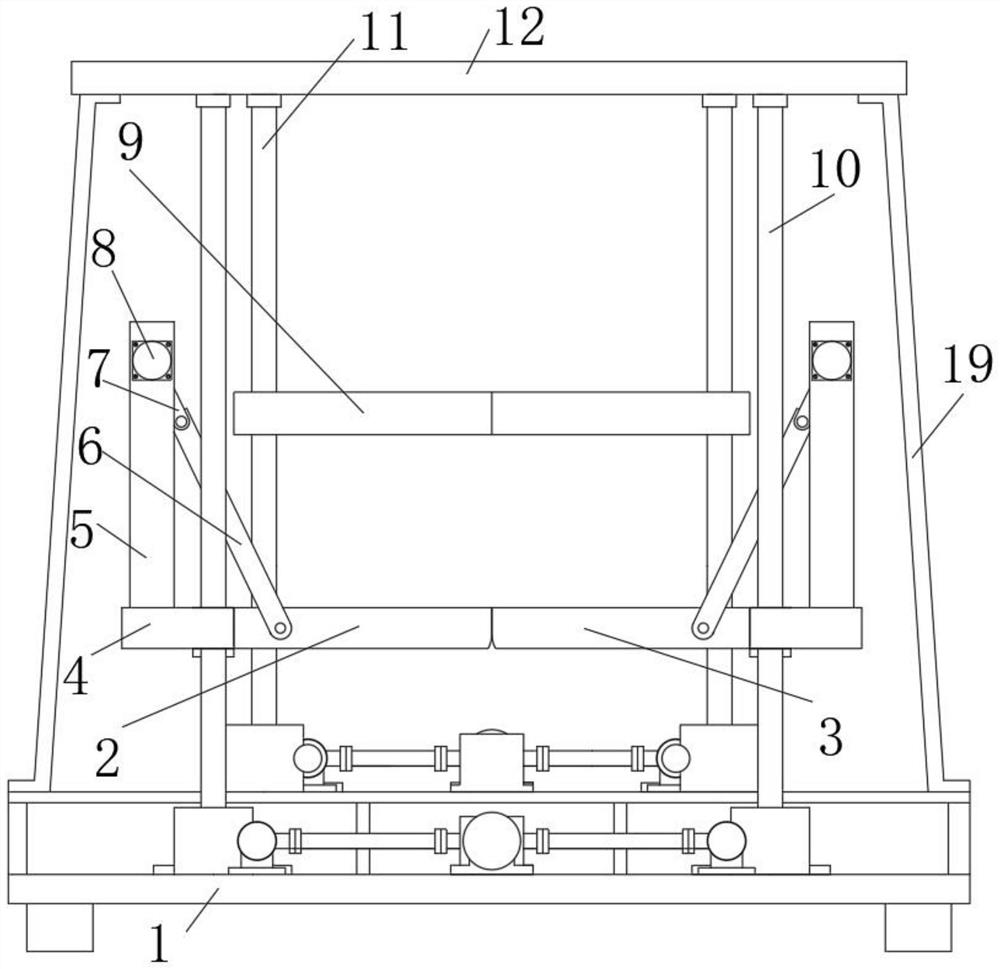

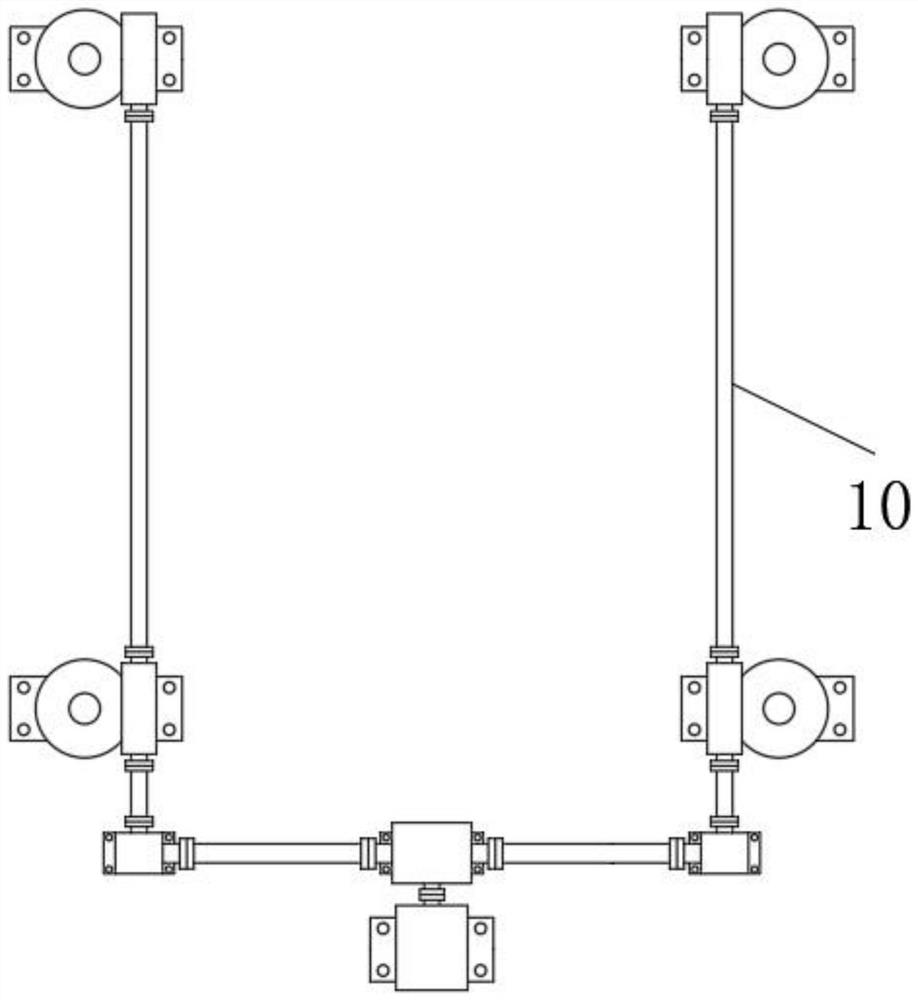

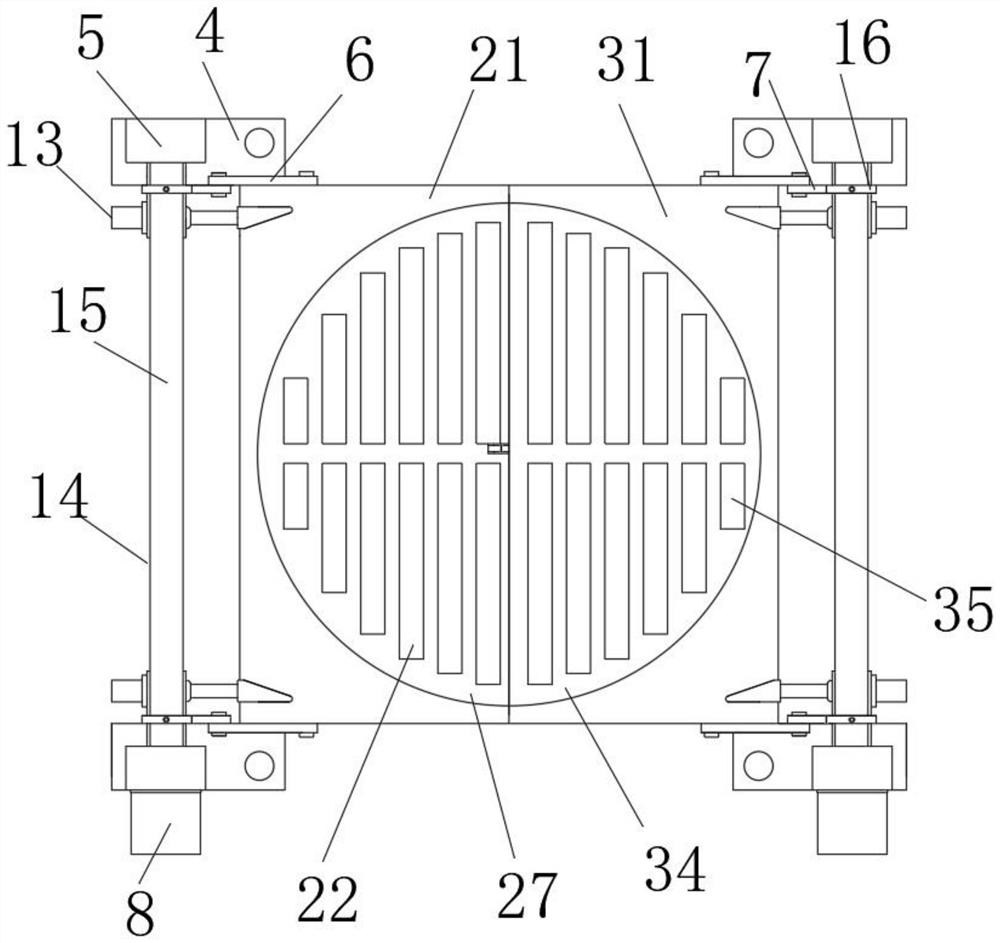

[0039] see Figure 1-21 In this embodiment, a quick sorting device for warehouse logistics management is provided, including a base 1, a support rod 19 and a top plate 12, the four corners of the upper end of the base 1 are fixed with screws to install the support rod 19, and the upper end of the support rod 19 is passed through Screws are fixedly connected to the top plate 12, and the base 1 is divided into upper and lower two-layer structures. The lower layer of the base 1 is fixed with bolts to install the synchronous screw lifting platform 10, and the upper layer of the base 1 is fixed with bolts to install the synchronous screw lifting platform 2 11, and the synchronous screw The top of the lifting platform 10 and the synchronous screw lifting platform 2 11 rotate to connect the top plate 12, the screw of the synchronous screw lifting platform 10 cooperates to connect the splicing sorting platform, and the screw of the synchronous screw lifting platform 2 11 cooperates and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com