LED lamp and heat dissipating structure thereof

A technology of LED lamps and heat dissipation structures, which is applied in lighting and heating equipment, cooling/heating devices of lighting devices, electrical components, etc., and can solve the problems of inconsistent heat dissipation requirements of LED lamps, increase in the number of heat pipes, and increase the manufacturing cost of heat dissipation fins, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the attached drawings are only provided for reference and illustration, and are not intended to limit the present invention.

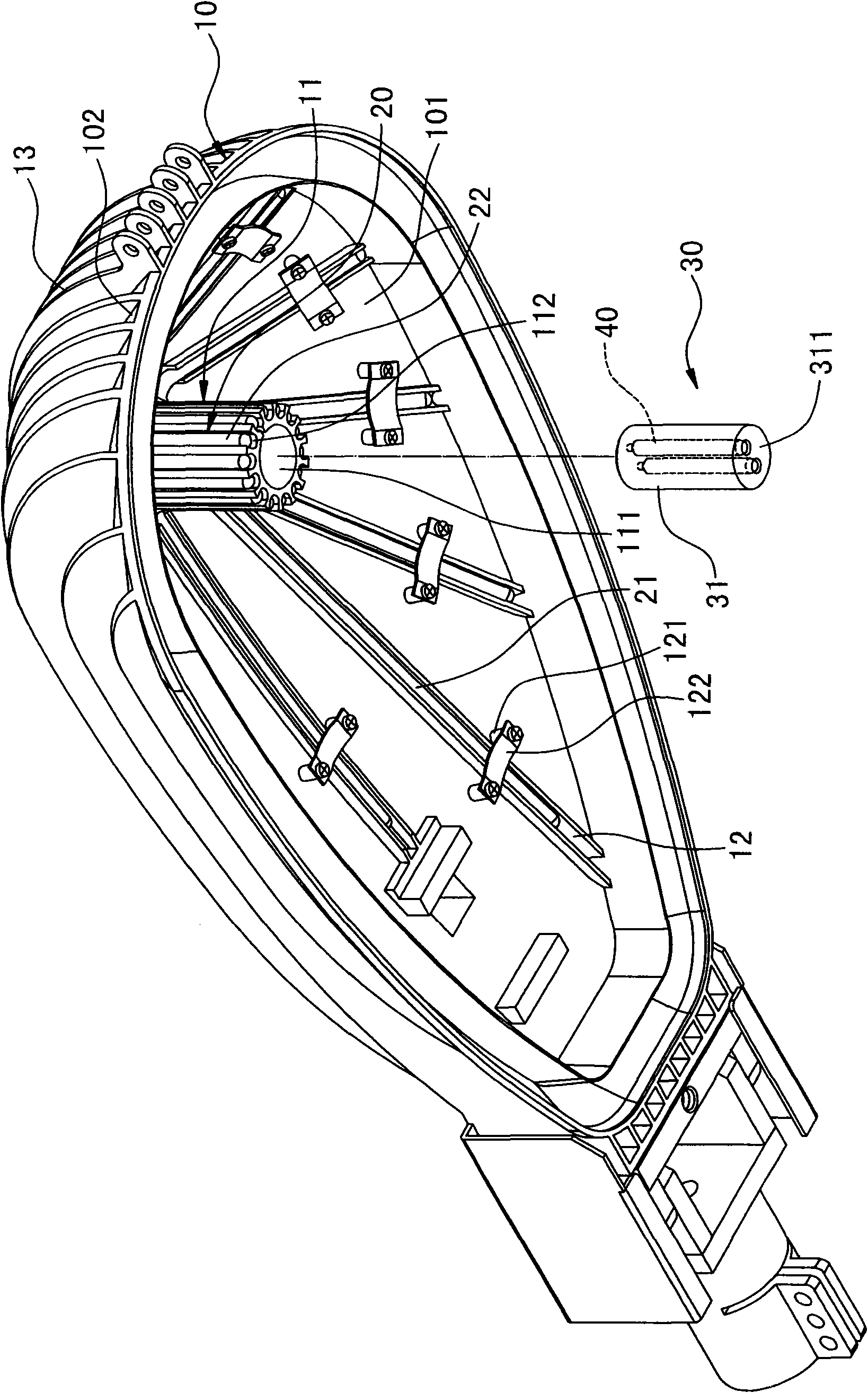

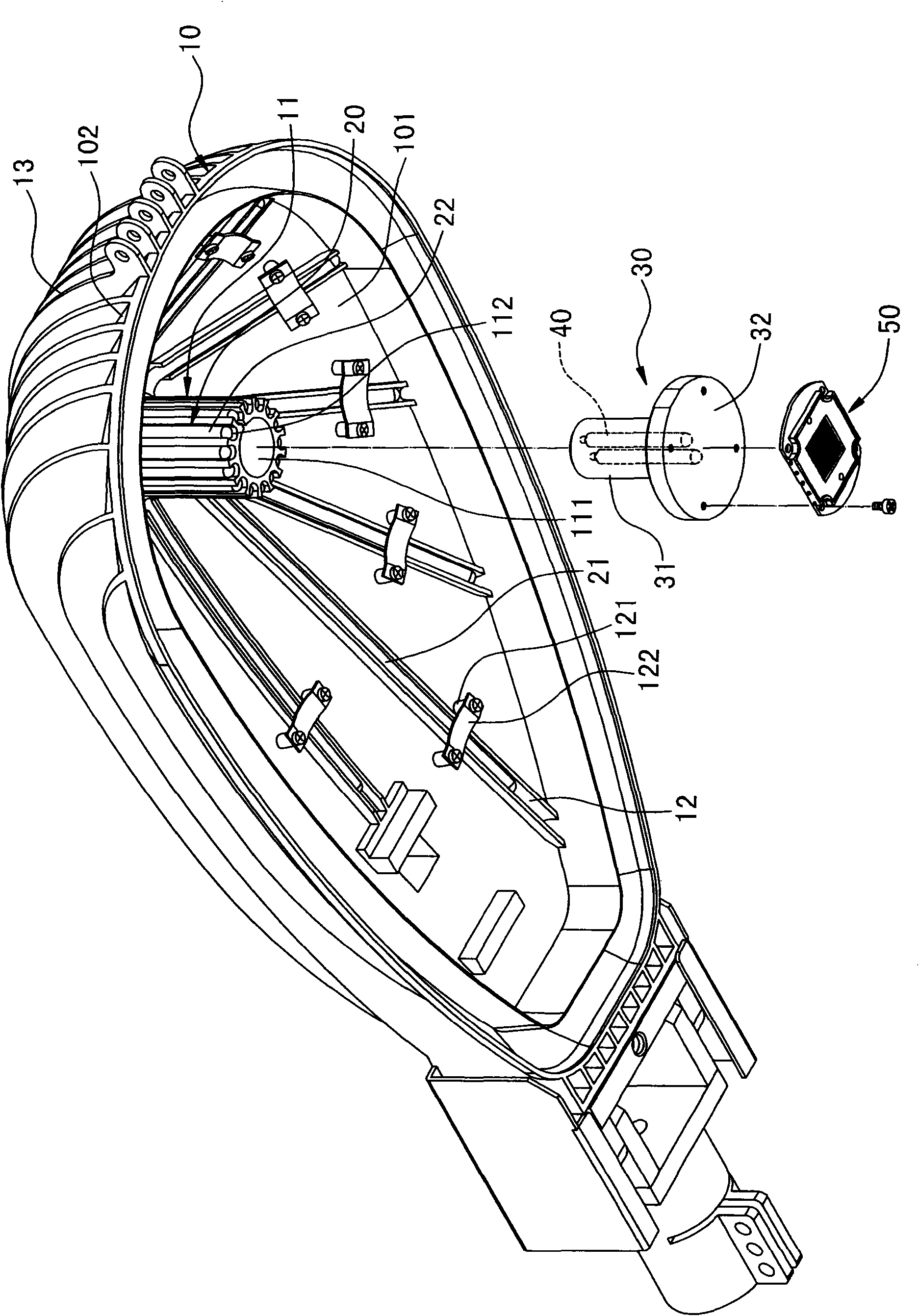

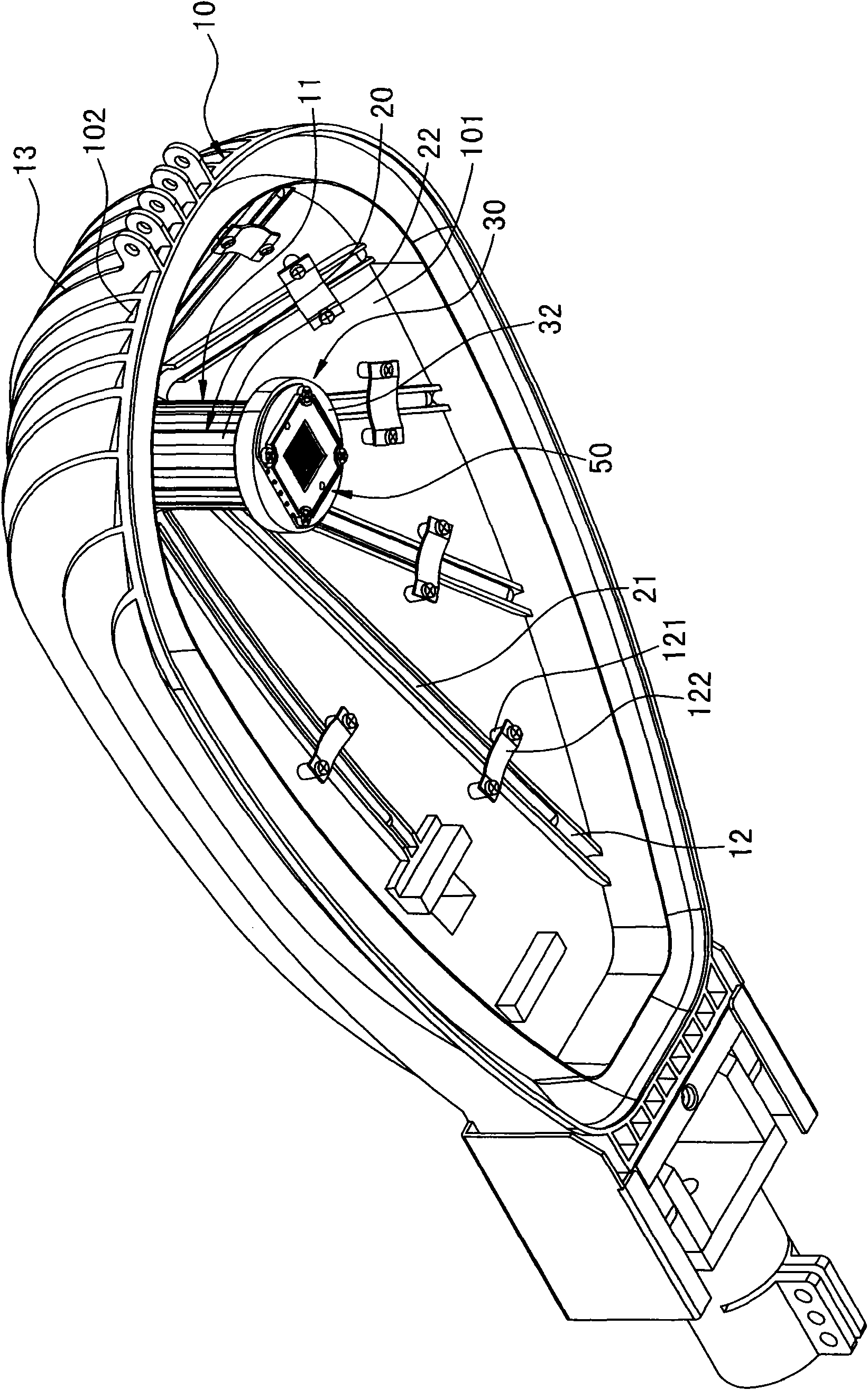

[0033] Please refer to figure 1 , is a three-dimensional combination diagram of the heat dissipation structure of the LED lamp of the present invention; it includes a lampshade 10, and a plurality of heat dissipation fins 13 can be formed on the outer surface, inner surface or inner and outer surfaces of the lampshade 10, and in this embodiment, a plurality of heat dissipation fins 13 are formed on the outer surface The surface 102 is provided with a plurality of heat dissipation fins 13, and a first heat conduction column 11 extends along the inner bottom surface 101 of the cavity. Holes 112, the axis lines of these accommodation holes 112 are parallel to the axis line of the first heat conduction column 11, in this em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com