A kind of environmental protection paint and its preparation system and environmental protection paint processing method

An environmentally friendly coating and preparation system technology, applied in the field of coatings, can solve the problems of inconvenient storage of raw materials, inconvenient discharge of raw materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

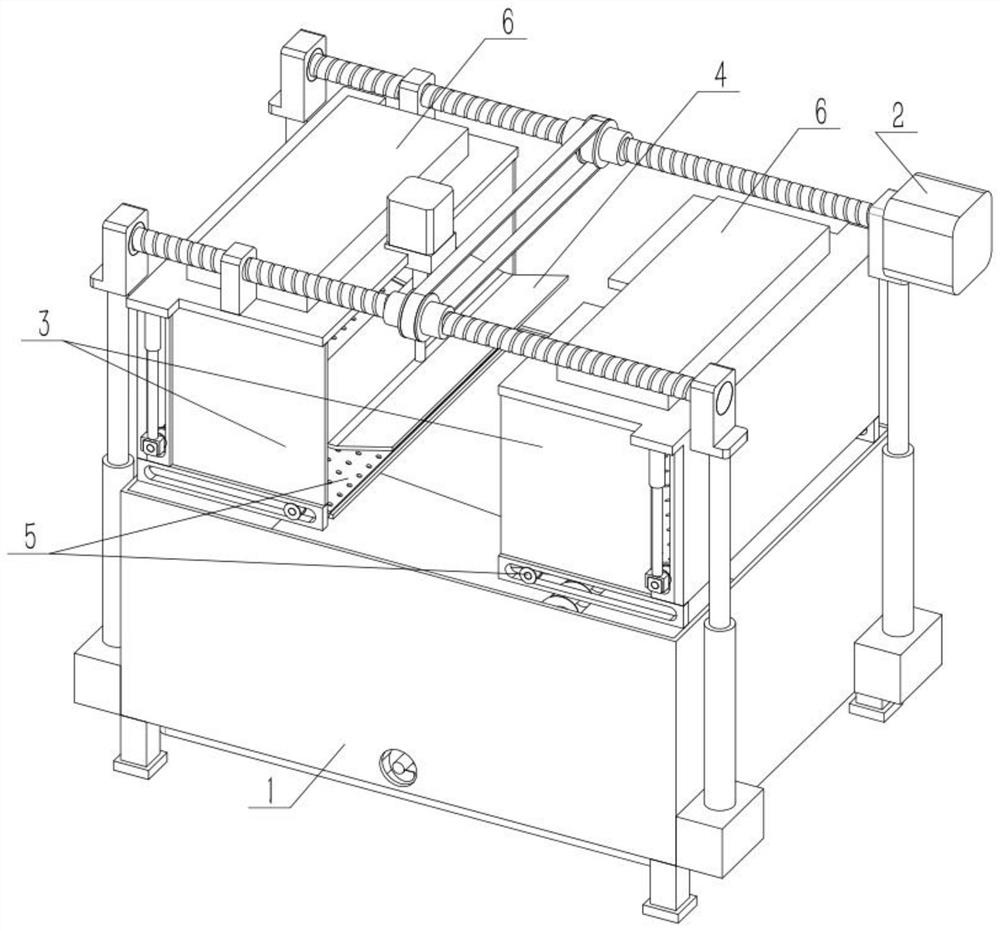

[0032] Such as Figure 1-7 As shown, a kind of environment-friendly paint preparation system comprises a powder material box 1, a moving frame 2, an insertion bin 3, a disperser 4 and a shifting shovel 5, the powder material box 1 is fixedly connected with a moving frame 2, Two insertion chambers 3 are provided in mirror image symmetry, and the two installation chambers 3 are threadedly connected with the master frame 2, and the breaker 4 is fixedly connected to the inner side of the upper end of one of the installation chambers 3, and two displacement shovel plates 5 are arranged in mirror image symmetry. The two displacement shovels 5 are respectively connected with the two placement bins 3 . The flexible use of the two placement bins 3 and the two shifting shovels 5 can dehumidify, de-agglomerate and quickly disperse the moisture of the paint raw materials, and is conducive to the complete transportation of the paint raw materials.

specific Embodiment approach 2

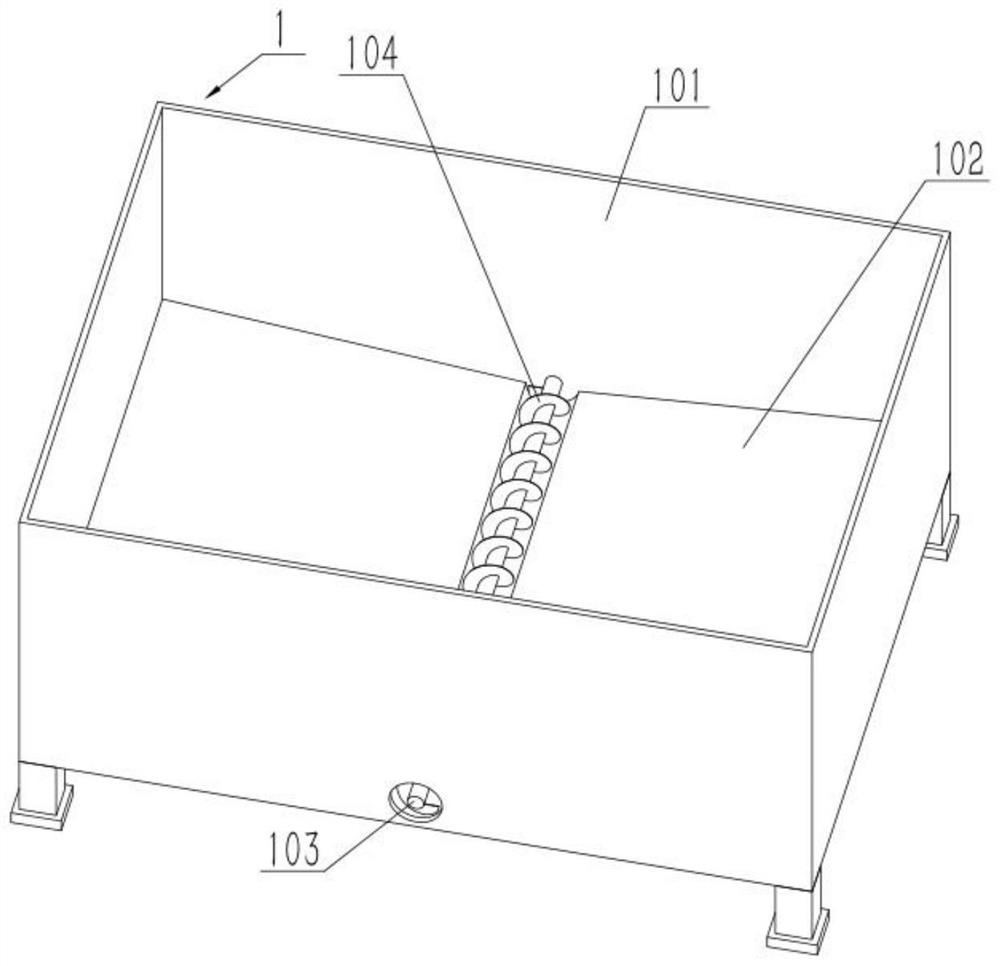

[0034] Such as Figure 1-7 As shown, the powder box 1 includes a powder container 101, a bottom surface 102, a first shaft 103, a screw blade 104 and a first motor 105, the bottom of the powder container 101 is provided with a bottom surface 102, and the middle part of the bottom surface 102 is provided with a half The arc-shaped groove, the left and right sides of the bottom surface 102 are sunken into the groove, the groove is connected with the rear end of the powder container 101, the first axis 103 is arranged in the groove, the first axis The front end of 103 is rotatably connected with the front end of the powder container 101 , and a helical blade 104 is installed on the first shaft 103 . The bottom surface 102 facilitates the concentration of raw materials to the spiral blade 104 .

specific Embodiment approach 3

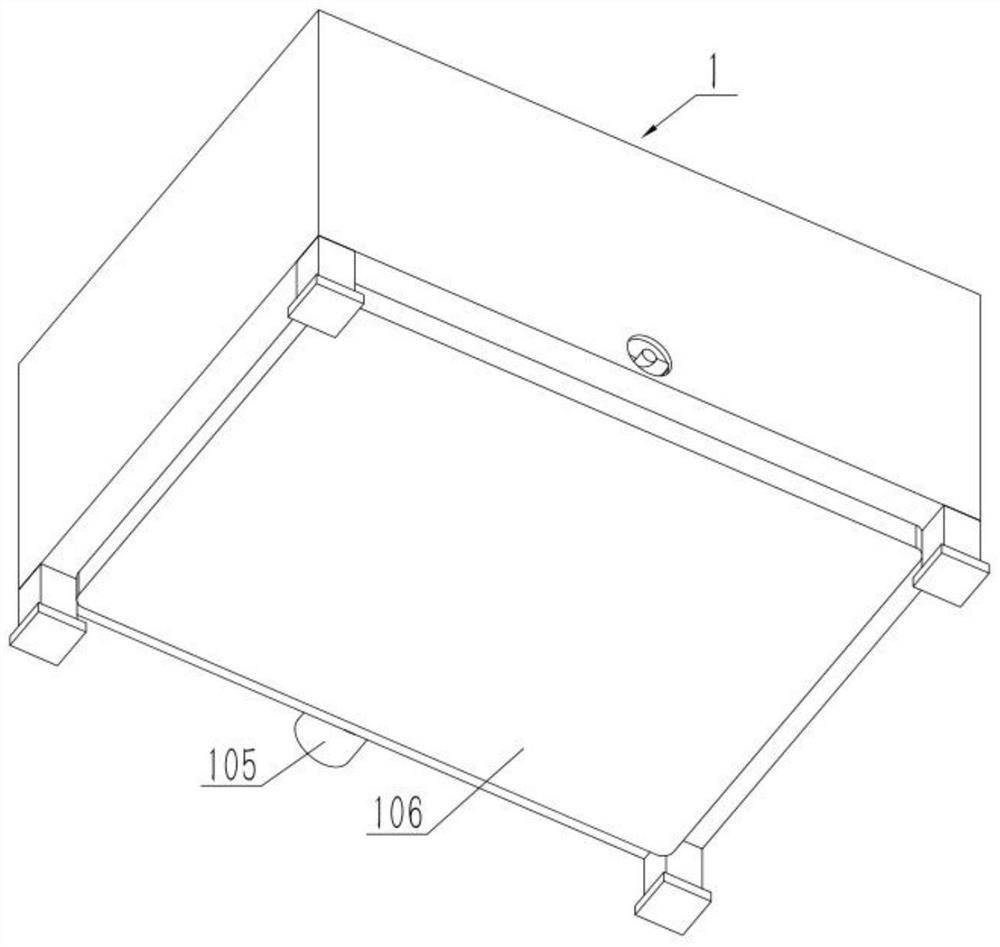

[0036] Such as Figure 1-7 As shown, the powder box 1 also includes a first heating device 106 installed at the lower end of the powder container 101 . The first heating device 106 can use resistance heating or other heating methods to heat up the bottom of the powder container 101, and at the same time combine the support structure to make the bottom of the powder container 101 higher than the ground and in this space above the ground not damp.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com