Nut insert hot melting workstation arrangement structure and hot melting process method

A technology for arranging structures and workstations, which is applied to household components, household appliances, and other household appliances. It can solve problems such as low positioning and clamping accuracy, affecting hot-melt precision, and inability to hot-melt operations, etc., to achieve a simple layout structure. Compact, improved welding quality, easy and simple welding operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

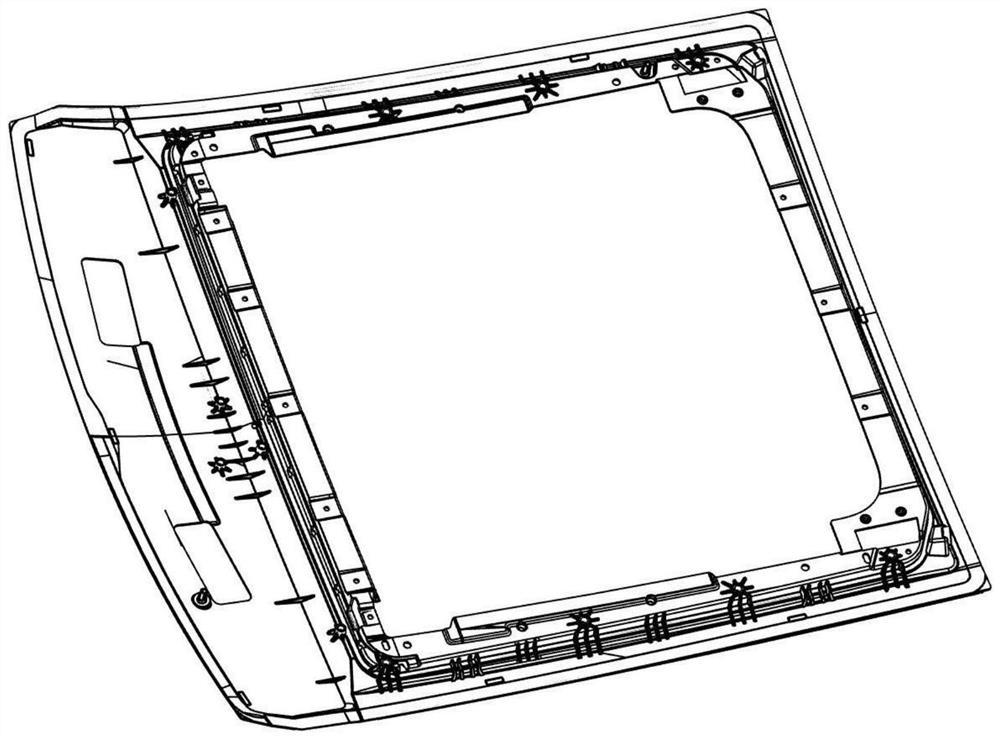

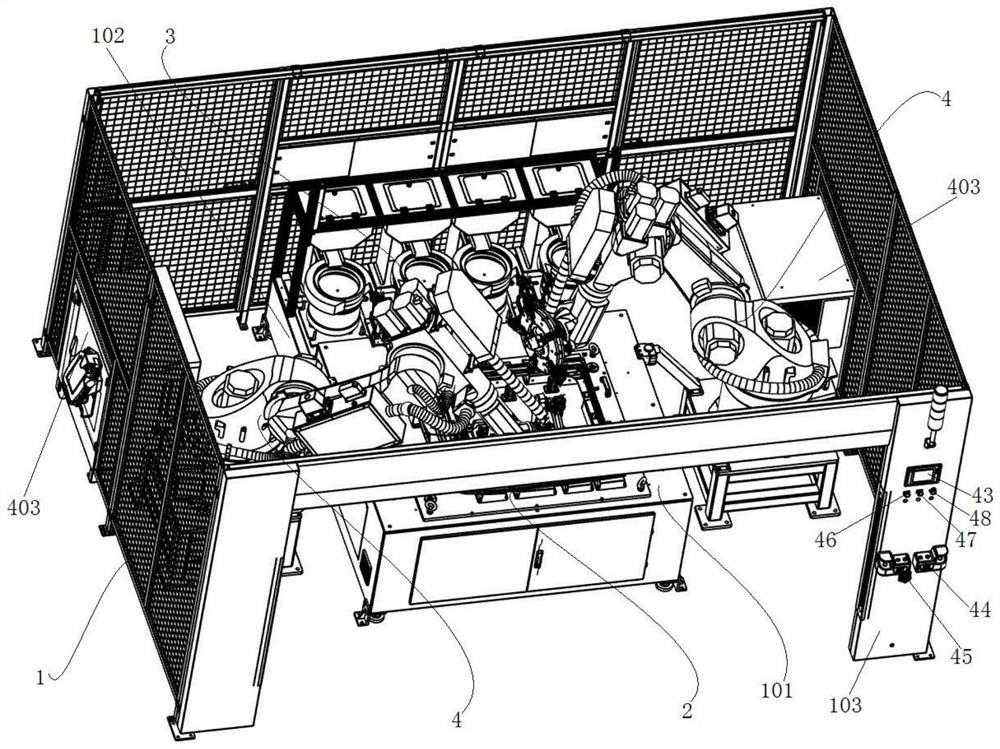

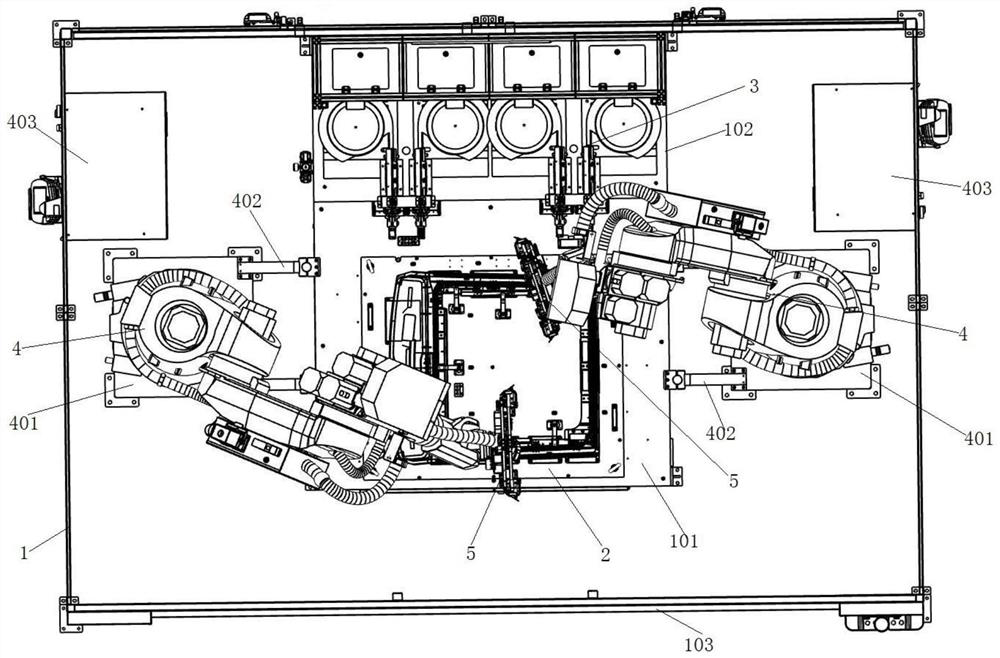

[0052] Such as figure 2 and image 3 As shown, an arrangement structure of a nut-type insert hot-melt workstation includes a workstation frame 1, a gantry frame 103 is provided on the front of the workstation frame 1, and a main workbench 101 is provided in the middle of the workstation frame 1. An auxiliary workbench 102 is provided between the workbench 101 and the back of the workstation frame 1; the main workbench 101 is provided with a positioning fixture assembly 2, and the auxiliary workbench 102 is provided with an automatic feeding assembly 3. The discharge chute 25 of the automatic feeding assembly 3 extends to and is connected to the main workbench 101; the two sides of the main workbench 101 are respectively provided with a robot 4, and the free end of the robot 4 is connected with a retrieving assembly 5 , the workstation frame 1 is respectively provided with a robot electric control box 403 connected with the corresponding side robot near the robot 4; , the co...

Embodiment 2

[0083] This embodiment provides the hot-melt process method of the workstation with the arrangement structure in the first embodiment.

[0084] The hot-melt process method is as follows: press the power button 46 and the lighting system button 47, turn on the lighting system of the workstation, wait for the human-computer interaction screen 43 to start; enter the control program of the human-computer interaction screen 43 and click the human-computer interaction Each robot calls the program on the screen operation page, and the green light of each robot status is on; click the operation page in manual mode, turn on the green robot power supply, vibration plate power supply, electric heating tube and heating rod power supply, and wait for the temperature to rise to the thermal melting value. Turn the hand-automatic mode switching knob 48 to automatic, and press the hot-melt start button 44 to start the hot-melt operation;

[0085] In the process of waiting for the temperature t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com