Induction heating continuous magnesium-smelting system and continuous magnesium-smelting technique

A technology of induction heating and magnesium smelting, applied in the field of induction heating continuous reduction magnesium smelting system, can solve the problems of short life of reduction tank, increased secondary loss of magnesium, and increased burden of magnesium refining process, etc. The effect of improving heat utilization efficiency and shortening reduction reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, but it is by no means intended to limit the scope of the present invention.

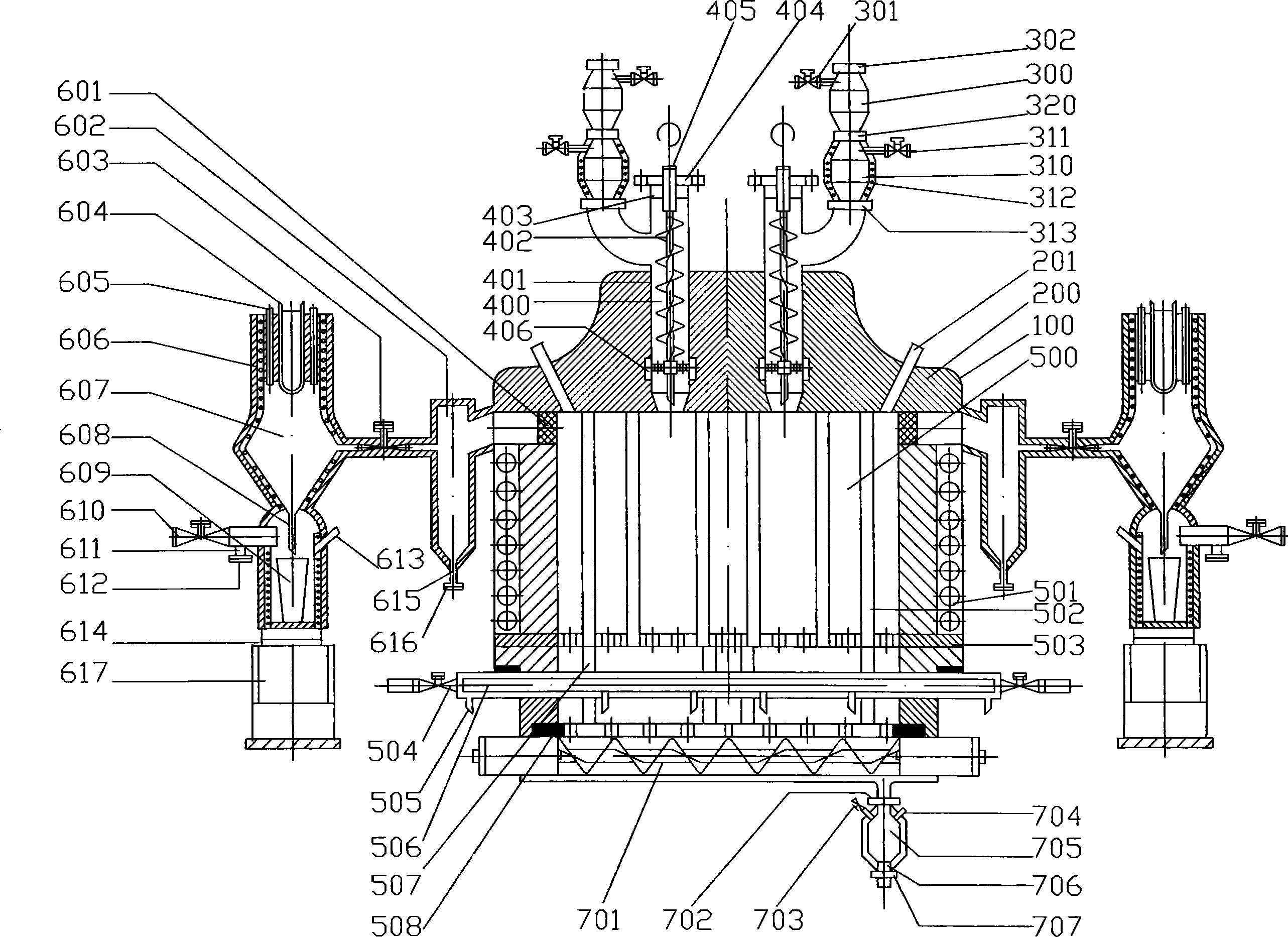

[0026] a. The induction heating continuous magnesium smelting system designed by this patent is shown in the attached figure, including a set of continuous feeding device, an induction heating reaction chamber, two sets of condensing devices for condensing magnesium steam into liquid magnesium, and a set of continuous slagging device .

[0027]b. The furnace shell 100 of the induction heating continuous magnesium smelting system is welded by steel plates, the steel plate is made of A3 steel or No. 45 steel, and the thickness of the steel shell is 10-30 mm; the furnace shell is lined with a heat-insulating refractory layer 200; The furnace body is provided with more than two first observation holes 201, so as to observe the condition of the material level in the furnac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com