Beam down system solar generation device

A technology of solar thermal power generation and solar light, which is applied in the direction of solar thermal devices, solar thermal power generation, heating devices, etc., can solve the problems of central reflector 110 skew or offset, low endurance, and inability to improve strength, etc., and achieve lightening Effects of blocking phenomenon and shadowing phenomenon, improvement of shock resistance and strength, and prevention of shifting of the optical axis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

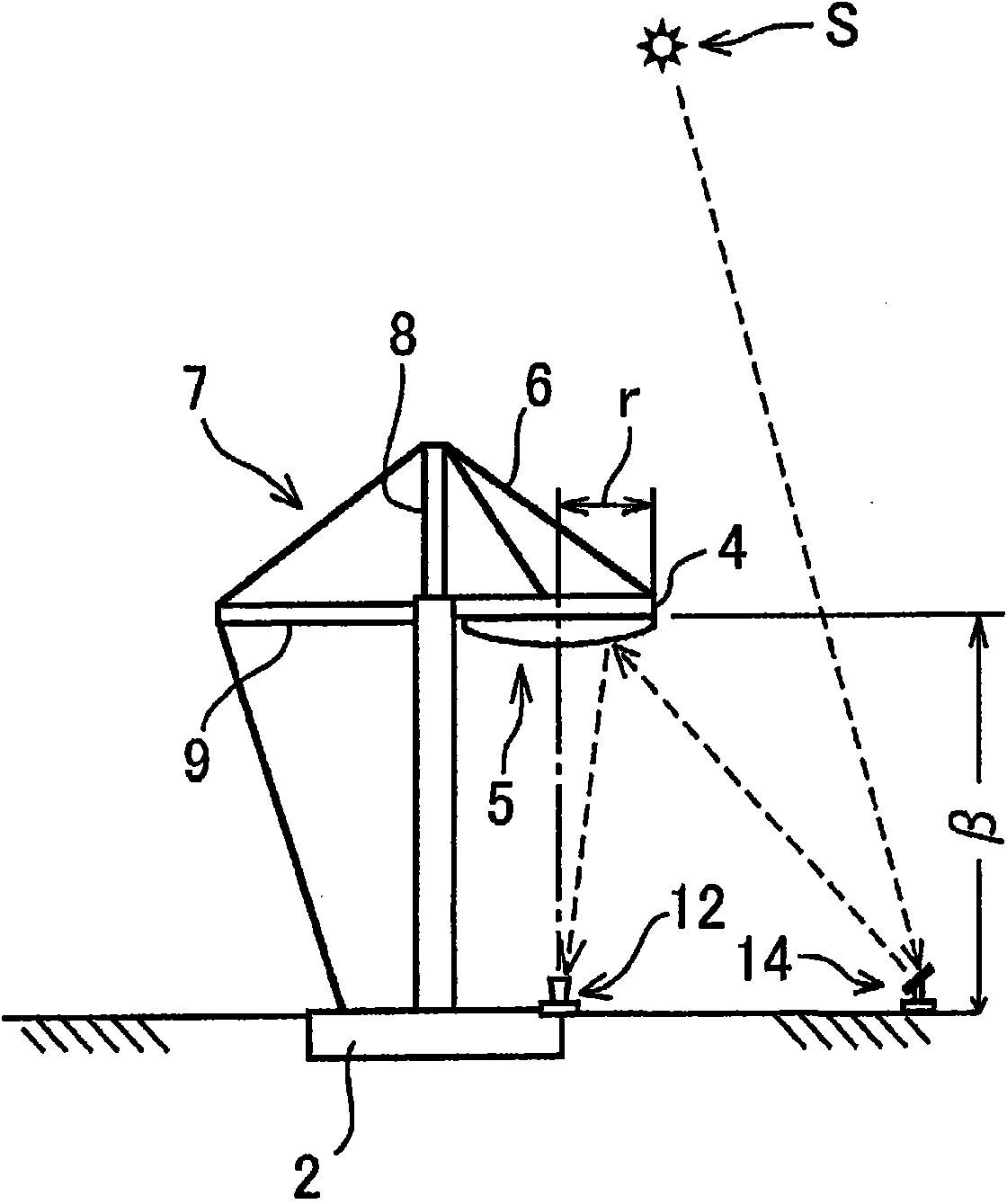

[0055] Such as figure 1 As shown, in the solar thermal power generation device A, a central reflector 5 is installed in a cantilevered manner on one side of the erected pillar 1, and a tower door 8 is erected on the top of the pillar 5. The above-mentioned central reflector 5 is fixed by the brace material 7, and the above-mentioned pillar 1 is supported by connecting the above-mentioned pylon 8 and the protruding material 9 protruding on the back side of the above-mentioned pillar 1 and the brace material 7 of the base 2.

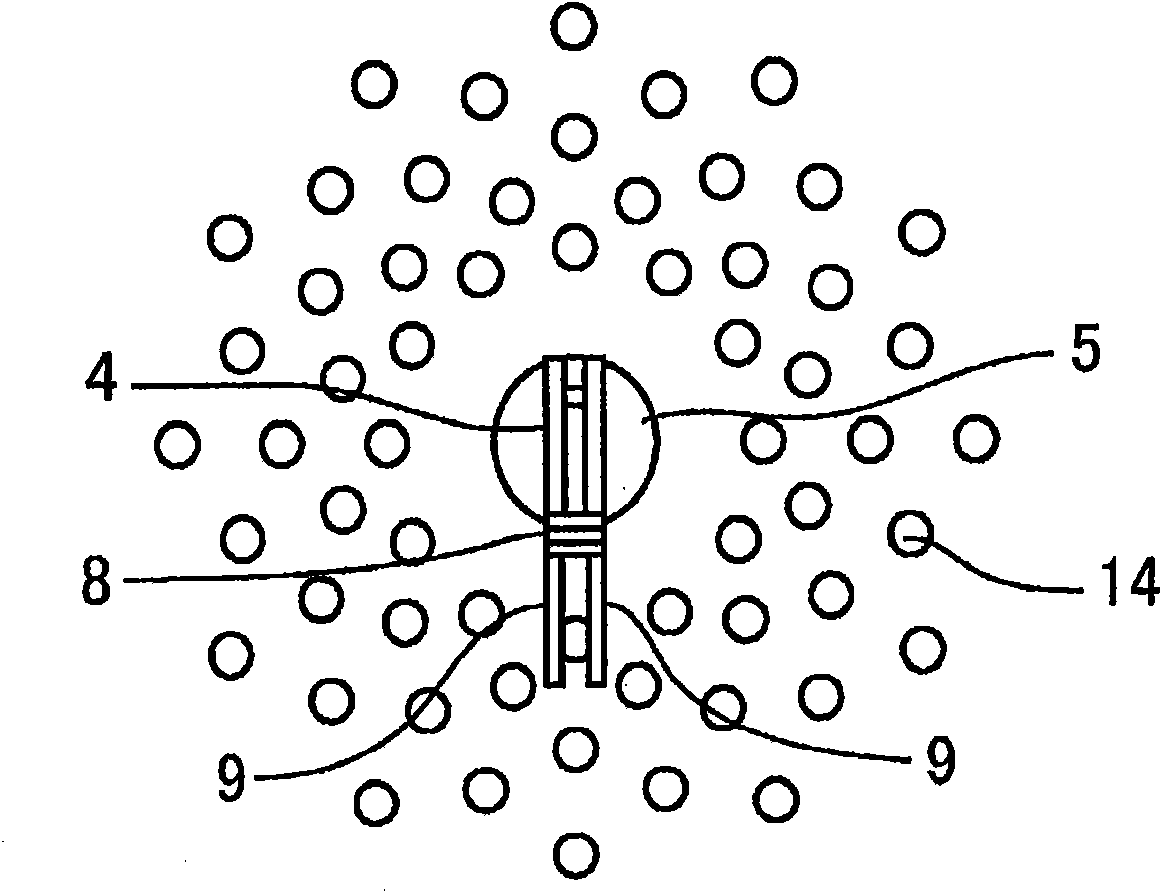

[0056] Furthermore, if figure 2 As shown, many heliostats 14 are concentrically arranged around the pillar 1 on which the central reflector 5 is mounted in a cantilever shape, and are arranged so that the north side of the pillar 1 is denser than the south side of the pillar 1 .

[0057] In the solar thermal power generation device A constituted in this way, many heliostats 14 reflect sunlight, and the reflected light is reflected on the central reflect...

Embodiment 2

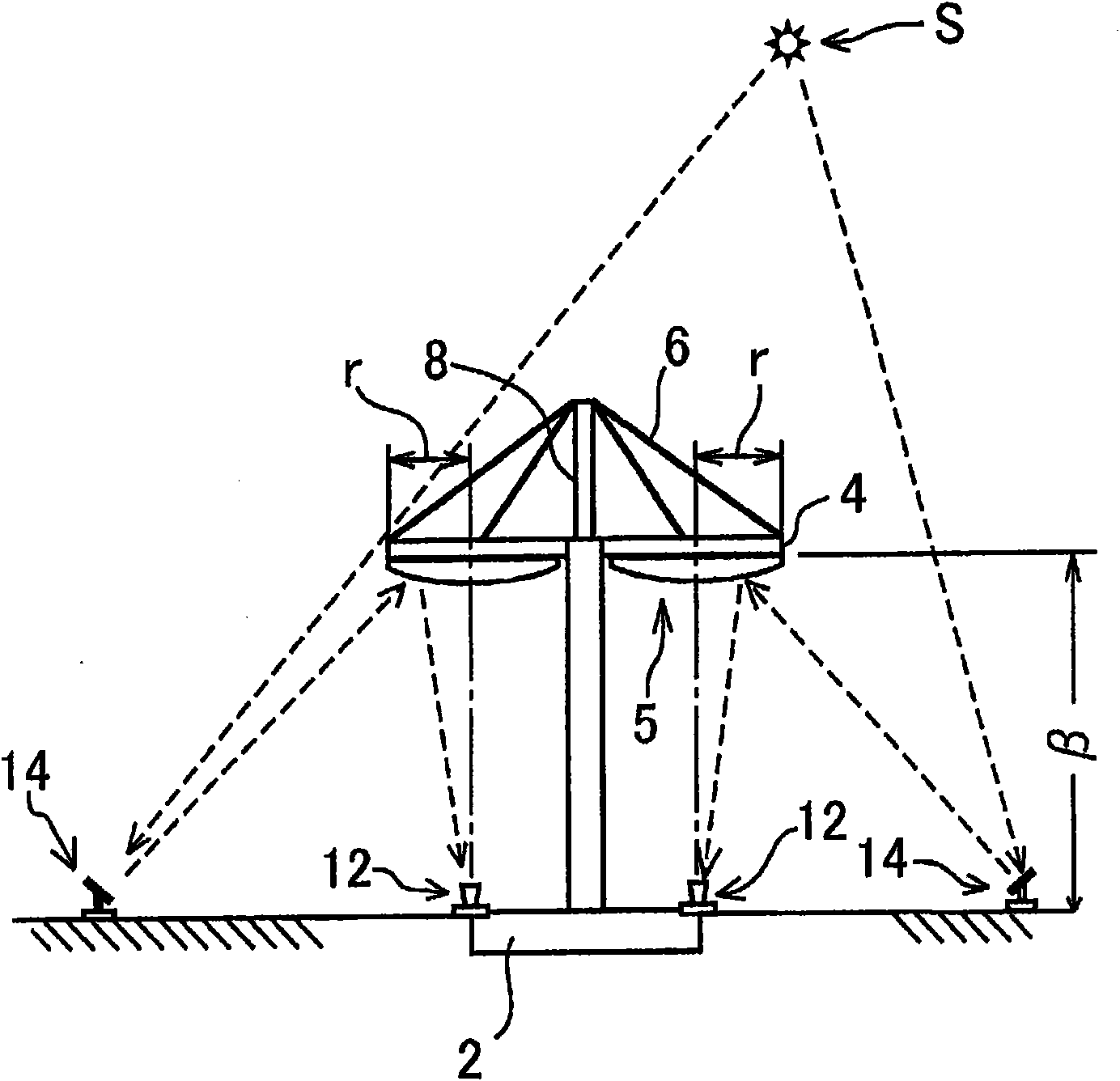

[0060] In the solar thermal power generation device A of this embodiment, if image 3 and Figure 4 As shown, two central reflectors 5, 5 are provided on the central pillar 1. As shown in FIG. Specifically, such as Figure 4 As shown, it is equipped with: a plurality of heliostats 14 that reflect sunlight; central reflectors 5, 5 that condense the reflected light reflected by the heliostats 14 to the heat medium heating units 12, 12; and A steam turbine power generation unit in which the heat medium heated by the above-mentioned heating unit 12 serves as a heat source. Furthermore, the above-mentioned center reflectors 5, 5 are provided in a cantilever shape on both sides of the above-mentioned pillar 1. As shown in FIG.

[0061] In addition, the said heliostats 5, 5 are installed so that the north side of a pillar may become denser than the south side of a pillar, and the reflection efficiency of sunlight may be improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com