Electrical connector with binding detection unit

An electrical connector and detection unit technology, which is applied in the direction of preventing wrong connection, etc., can solve the problems of larger space, higher cost, and increased number of components for electrical connectors, and achieves the effect of increasing the number of settings and achieving manufacturing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

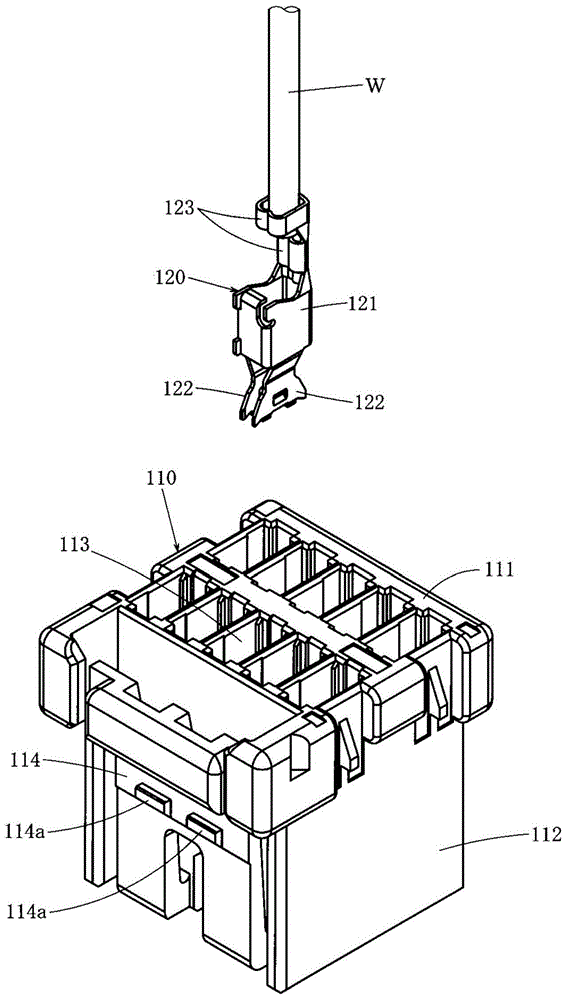

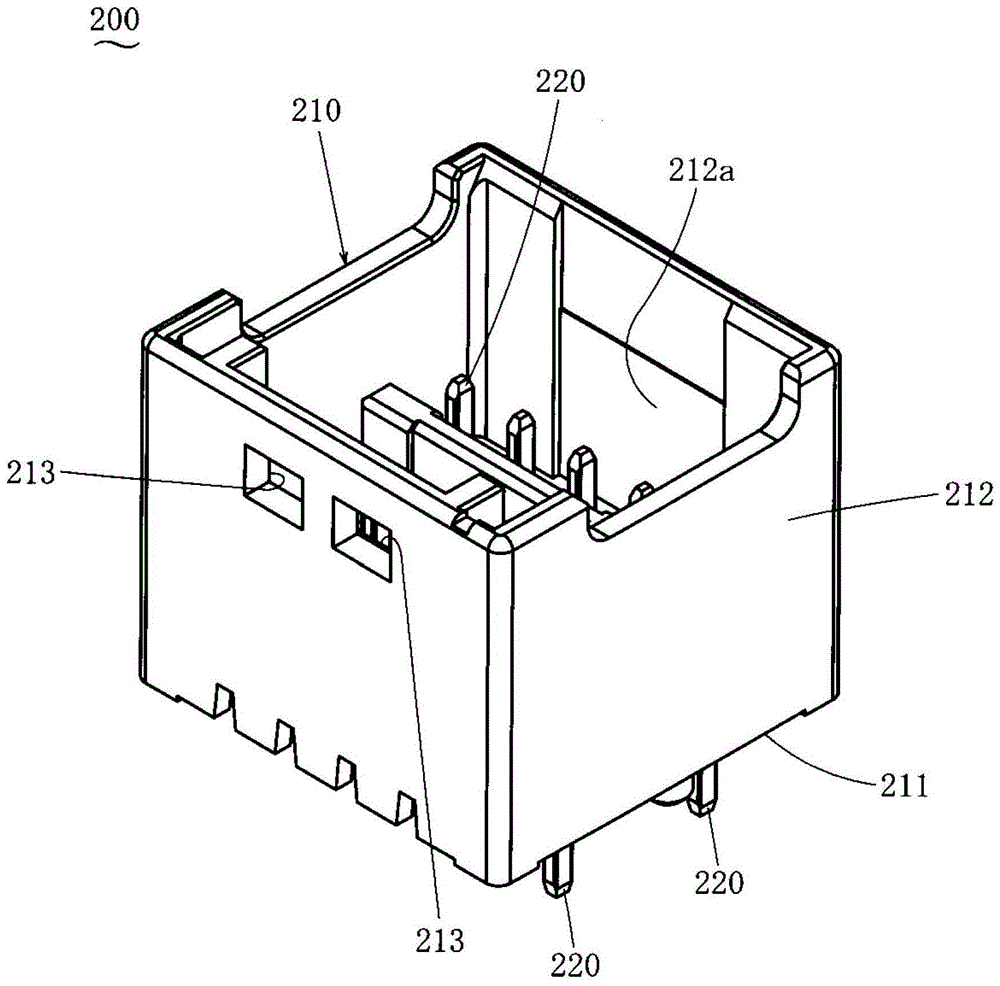

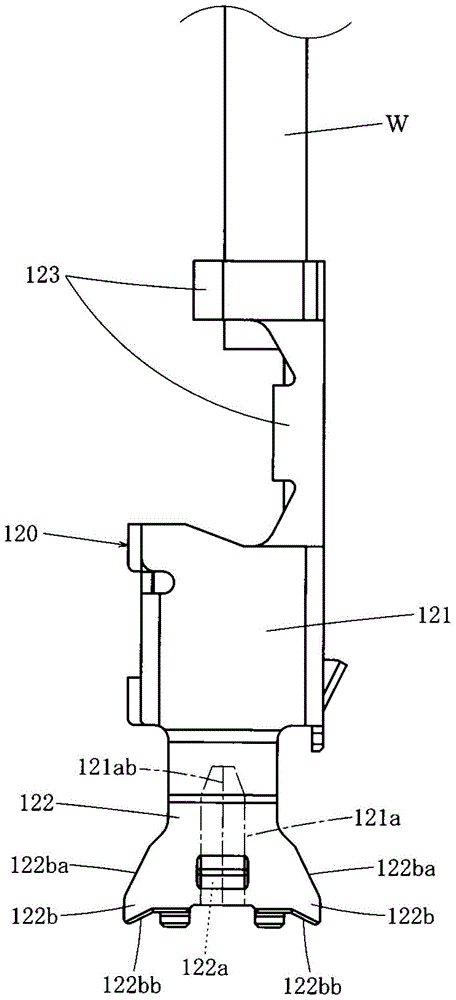

[0044] Next, embodiments of the present invention will be described. Figure 1 to Figure 17 An embodiment of an electrical connector with a combined detection unit of the present invention is shown. The electrical connector with a combination detection unit includes a first electrical connector 100 and a second electrical connector 200 . The mating side is defined as the side mated with the mating electrical connector, and the mating direction is defined as a direction toward the mating electrical connector when the mating sides face each other. Let the side opposite to the above-mentioned mating side be the anti-mating side, and let the direction opposite to the above-mentioned mating direction be the anti-mating direction. Hereinafter, when referring to the above-mentioned mating side or the above-mentioned mating direction, or the above-mentioned anti-mating side or the above-mentioned anti-mating direction with respect to the component or part, when the component or part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com